Technological method for pultrusion of glass fibre reinforced plastics pipe and die thereof

A technology of pultrusion and glass steel pipes, which is applied in the pultrusion of glass steel pipes, and in the field of special forming molds for this pultrusion method, which can solve the problems of restricting the application of pultrusion technology, mold blocking, and resin peeling on the inner wall. Achieve the effect of overcoming the wrinkle phenomenon of the felt layer, curing well, and avoiding uneven temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

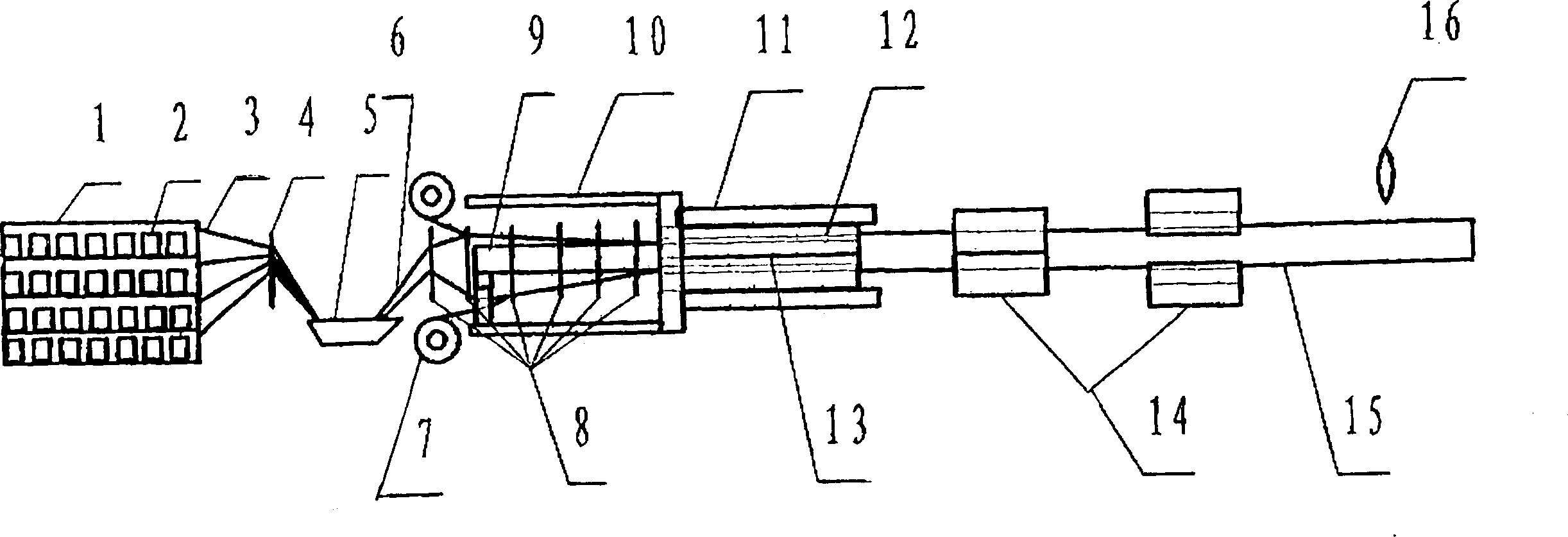

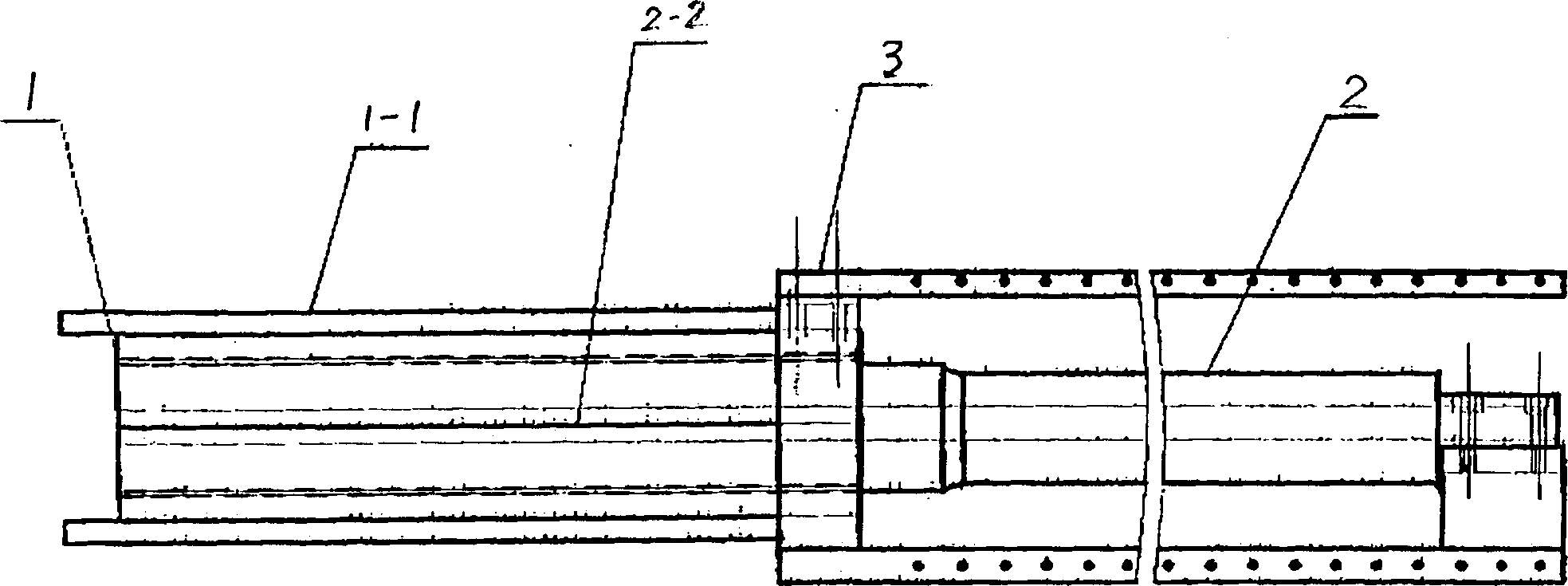

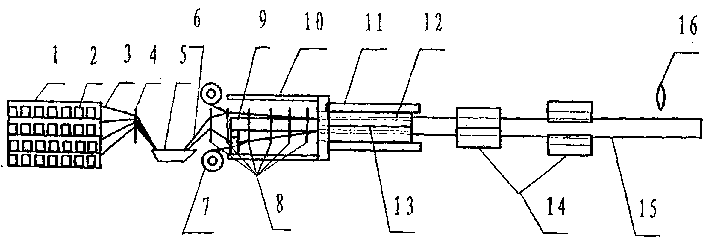

[0020] The product object of this embodiment is a glass fiber reinforced plastic cable protection tube with an inner diameter of 150 mm and a wall thickness of 3.3 mm. For the process, see figure 1 , where 1 is the creel, 2 is the yarn cluster, 3 is the yarn bundle, 4 is the yarn guide plate, 5 is the rubber tank, 6 is the dipped yarn, 7 is the felt roll, 8 is the reinforcing felt, and 9 is the mold core. 10 is a mold core support, 11 is a mold cavity heating plate, 12 is a mold cavity, 13 is a mold core heating device, 14 is a drawer head, 15 is a product, and 16 is a cutting device. The specific process steps are: A. Dipping yarn— ——Pull out the yarn end from the glass fiber yarn cluster on the creel and arrange it through the yarn guide plate

[0021] Finally, impregnate through the glue tank filled with resin ingredients; B, felt yarn compounding - use multiple glass fiber felts drawn from the felt frame to overlap to form two layers,

[0022] The glass fibe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com