Rotary oil gas mixing and equalizing distributor

A balanced distribution and rotary mixing technology, applied in distribution devices, textiles and papermaking, engine components, etc., can solve problems such as cloth and machine pollution, insufficient lubrication, excessive oil supply, etc., to achieve a clean working environment and ensure normal operation , Solve the effect of uneven oil supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

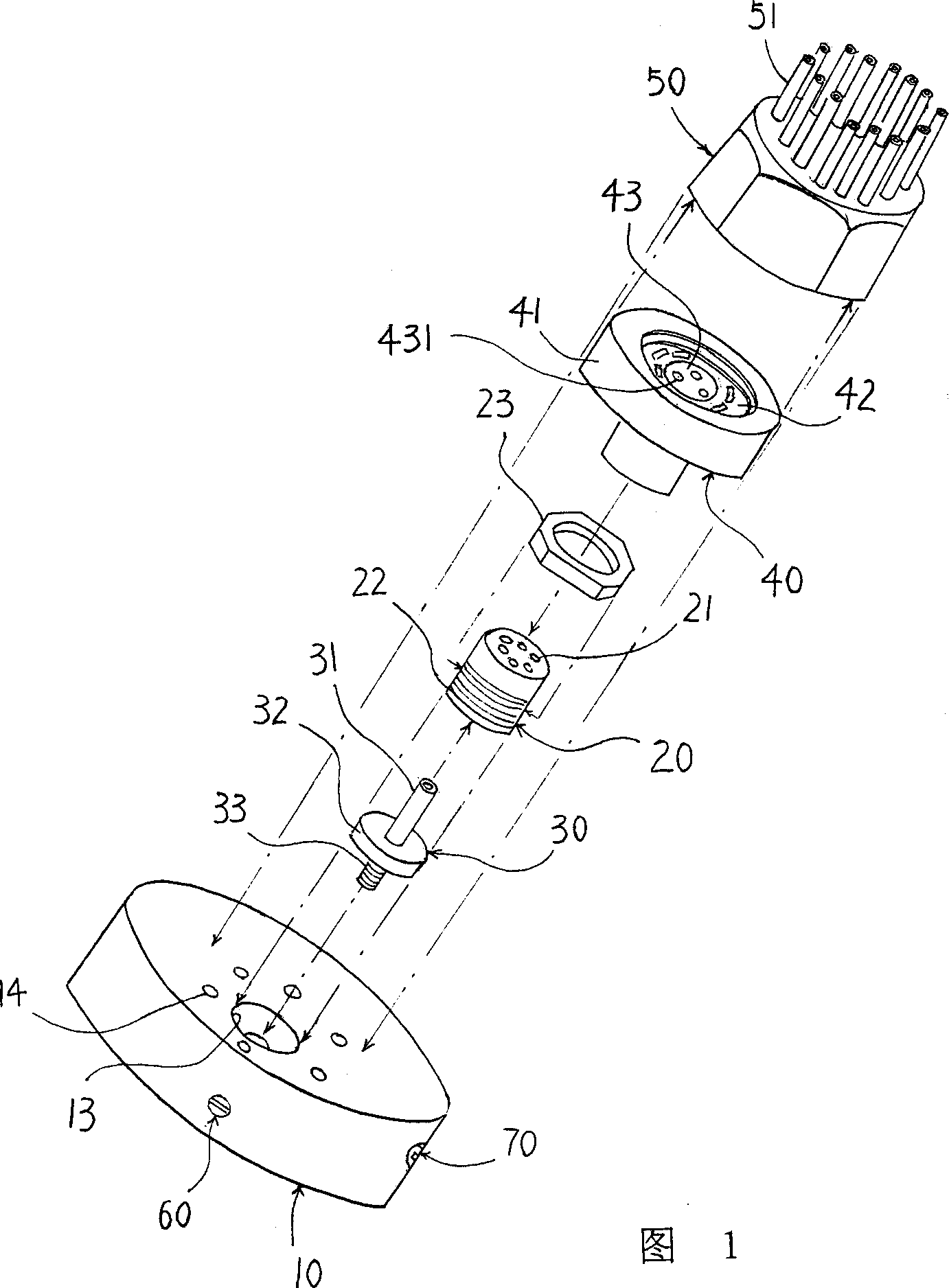

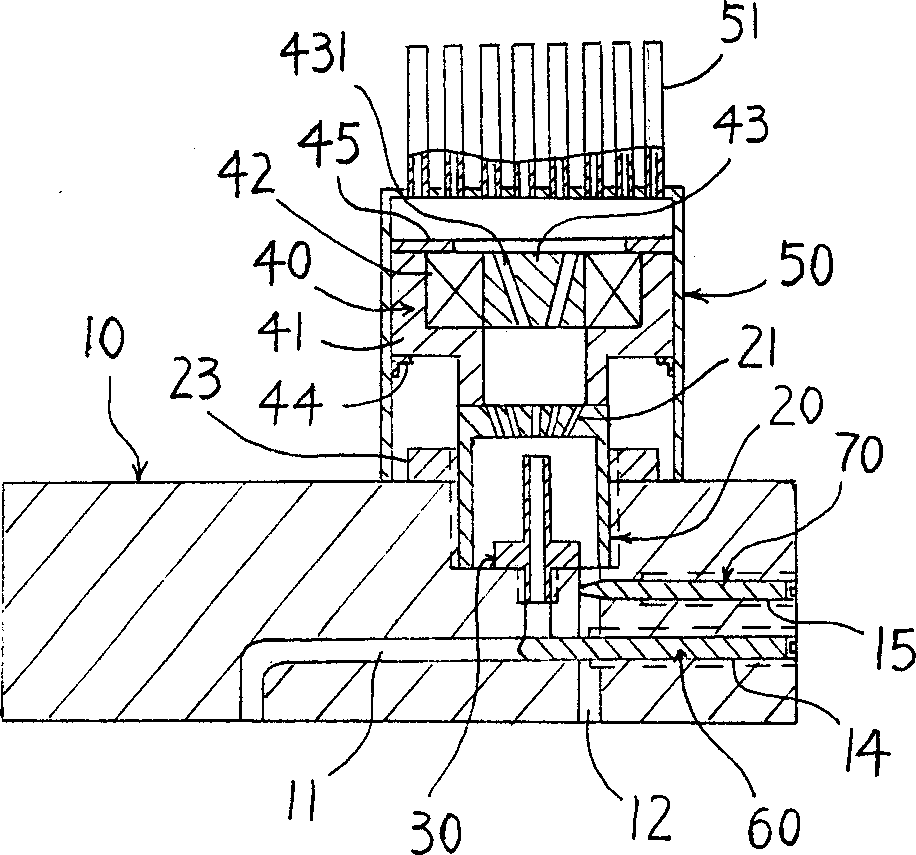

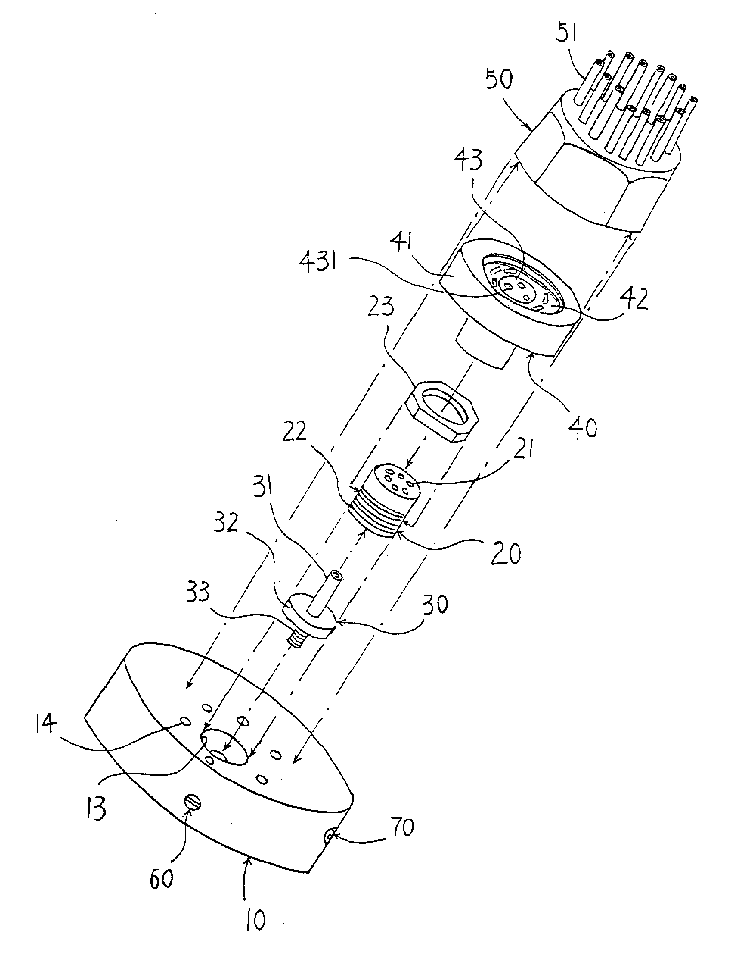

[0017] The rotary mixed oil-gas balanced distribution device of the present invention relates to a multi-channel lubricating oil balanced distribution device mainly used in circular knitting machines, and its structure is shown in Figure 1, figure 2 As shown, the device has a base 10, the base is disc-shaped, the base is provided with a mounting hole 13 for installing the oil-air mixing nozzle 20, and is provided with a lubricating oil channel extending from the bottom of the base to the mounting hole 11 and compressed air channel 12. An oil-air mixing nozzle 20 connected to the oil and gas passages is installed in the installation hole 13. The oil-air mixing nozzle is a hollow sleeve with an open bottom and a plurality of oil injection holes 21 on the top cover. The number is preferably 2 to 12, and the most optim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com