Improved process for primary treatment of sewage in urban area

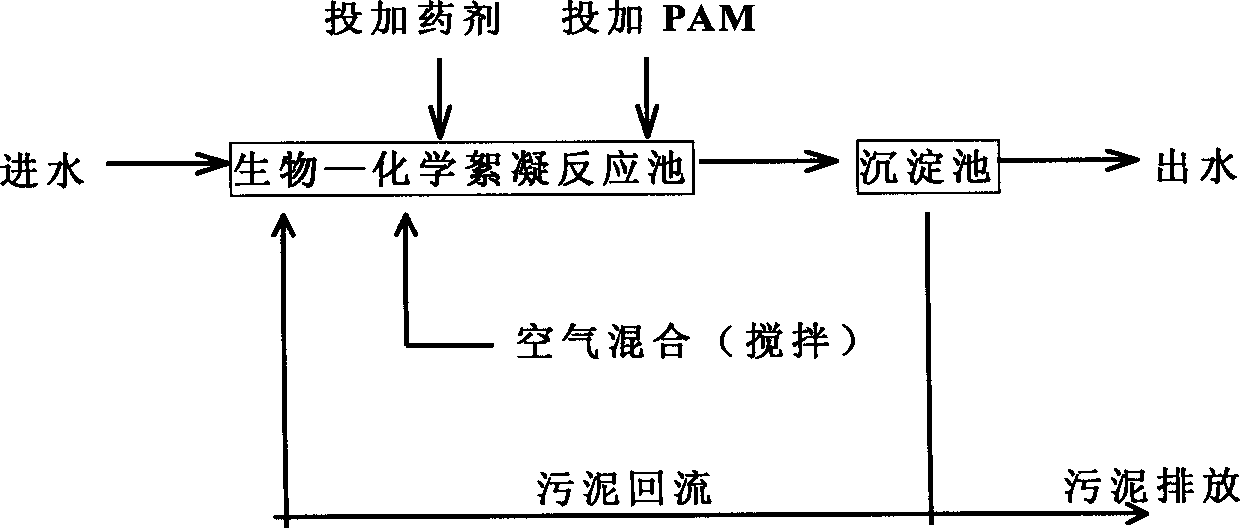

A treatment method and technology for urban domestic sewage, applied in the field of improvement of urban sewage intensified primary treatment method, can solve the problems of poor pollutant removal effect, low SS removal rate, large dosage of chemicals, etc., and achieve enhanced primary treatment effect, increase SS removal rate, removal rate and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0010] Embodiment: Example Influent, effluent pollutants and process parameters are shown in Table 2. The influent water is first mixed with the return sludge and aerated for adsorption and flocculation reaction for 10-30 minutes, and then Al is added 2 o 3 The liquid PAC with a content of 10% is flocculated for 10-15 minutes, and then the coagulant PAM is added for about 1-3 minutes to precipitate naturally. The sedimented sludge is broken by mechanical stirring for 5-10 minutes, and after standing still for 0.5-5 minutes, the upper layer of sludge is taken for activation. Aeration control dissolved oxygen concentration 0.5-3mg / l, activation time 1.5-5 hours, reflux. The remaining sludge is dehydrated and dried. The inlet of the flocculant is set in the middle area of the flocculation tank (including the middle, the near middle and the rear middle), and the inlet of the coagulant aid is set in the outlet area of the flocculation tank.

[0011] Table 1 The method of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com