Chip welding apparatus and/or lead binding apparatus with chip hold-down device

A chip bonder and wire bonding technology, applied in welding/cutting auxiliary equipment, auxiliary devices, welding equipment, etc., can solve problems such as wear marks of matrix substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

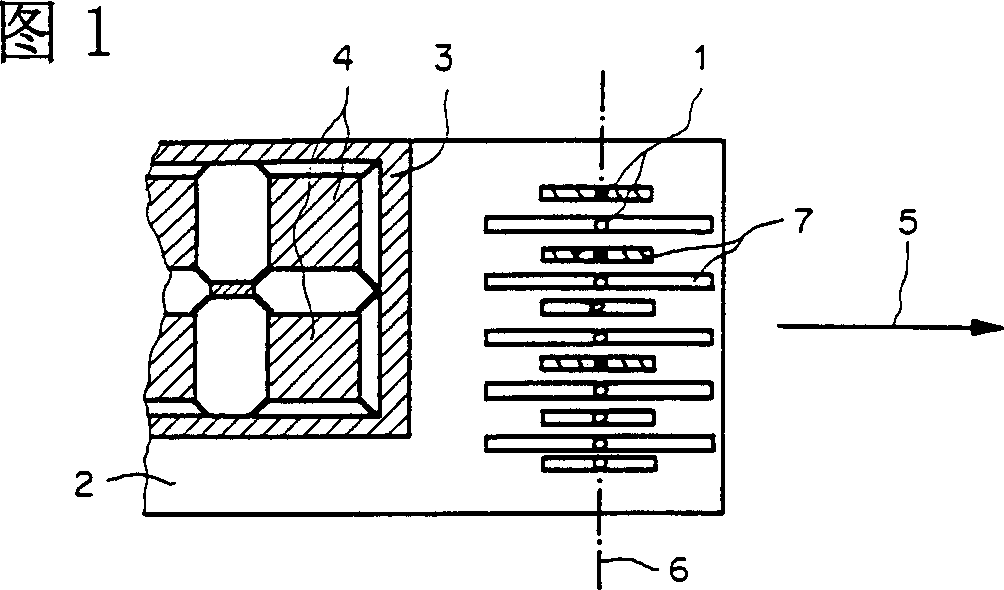

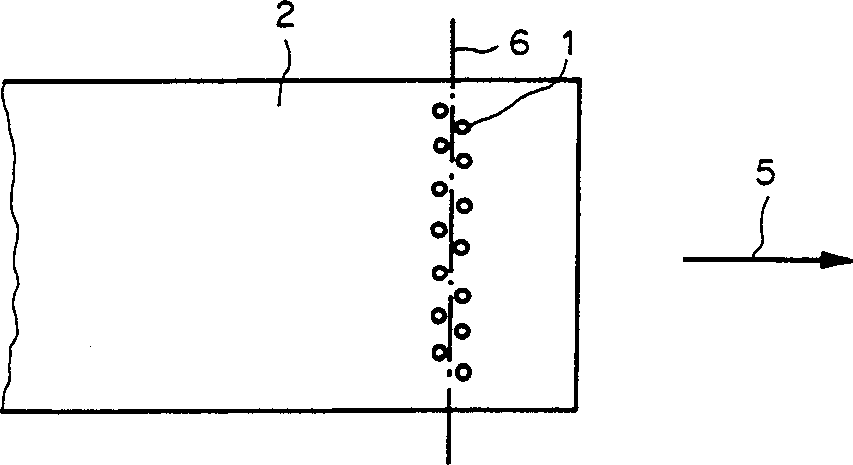

Embodiment 1

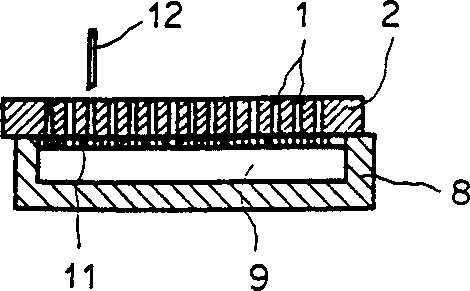

[0021] image 3 A cross-sectional view of the pressing device taken along line 6 in FIG. 1 is shown. The table 2 has a detachable drawer 8, the drawer 8 is combined with the bottom of the table 2, and a slot 9 is formed at the bottom of the drawer 8. During operation, the tank 9 is connected to a vacuum source. In addition, three cams 10 are arranged at the bottom of the drawer 8 (see Figure 4 ). The sheet 11 is inserted into the drawer 8 so that the cam 10 fits into the corresponding hole made in the sheet 11. For the sheet, it is preferable to use a rigid polyvinyl chloride (PVC) sheet such as that sold by VinK AG under the trade name VIKUNYL. The bore 1 of the table 2 is opened on the sheet 11 in the area of the groove 9. When a new type of substrate is reconfigured for the die bonder, the drawer 8 is pulled out, the new slice 11 lubricated by vacuum lubricating oil replaces the slice 11 inserted into the drawer 8, and then the drawer 8 is pushed Into Taiwan 2. In this case...

Embodiment 2

[0024] Figure 5 , 6 The embodiment shown is not suitable for matrix substrates, but is suitable for substrates without notches such as BGA Substrate. Figure 5 The table 2 shown in the top view has at least two cavities 20.1-20.6 with different lengths on the lower surface, and the cavities are connected to a continuous groove 19. In this embodiment, the number of cavities 20.1-20.6 is six. Similar to the first embodiment, this embodiment provides a drawer 8. Figure 6 The drawer 8 shown in has a surface 21 on which 6 cavities 22.1-22.6 are arranged. The cavities 22.1-22.6 have one lateral branch facing the groove 19 and two or three lateral branches facing the borehole 1. Before insertion, vacuum lubricant is applied to the surface 21. The surface 21 of the drawer 8 is placed on the lower surface of the table 2, so that the groove 19 forms a channel through which a vacuum can be applied. Vacuum lubricating oil can ensure that the channels and cavities 20.1-20.6 and cavities 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com