Method and equipment for transmitting information to ink-jet printing head

An inkjet print head and inkjet printing technology, applied in printing and other directions, can solve the problems of increasing the cost of the print head, increasing the cost, and multiple shielding steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

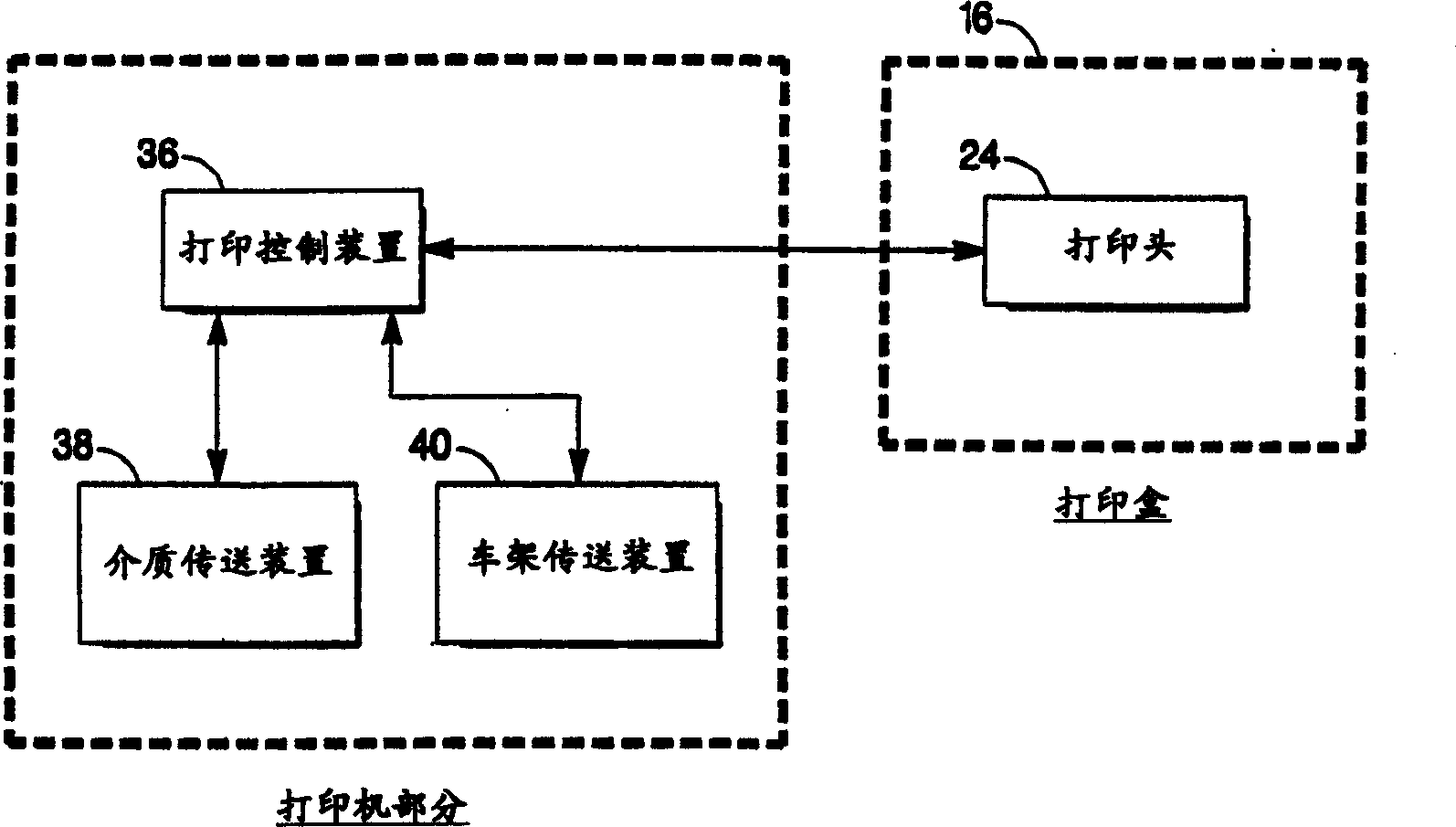

[0023] figure 1 It is a perspective view of an embodiment with the top cover of the inkjet printing system 10 of the present invention opened. Inkjet printing system 10 includes a printer portion 12 having at least one print cartridge 14 and 16 mounted in a scanning carriage 18 . Printer portion 12 includes a media tray 20 for receiving media 22 . Scanning carriage 18 moves print cartridges 14 and 16 through the print medium as print medium 22 is stepped through the print zone. Printer portion 12 selectively activates drop generators in a printhead portion (not shown) associated with print cartridges 14 and 16 to deposit ink onto a print medium, thereby effecting printing.

[0024] An important aspect of the present invention is the method by which printer portion 12 communicates drop generator activation information to print cartridges 14 and 16 . This drop generator activation information is used by the printhead portion to activate the drop generators as the print cartri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com