Method of controlling single spindle driving motor of spinning machine

A technology for driving motors and spinning machines, which can be used in spinning machines, continuously wound spinning machines, electronic commutators, etc., and can solve problems such as complex structure and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

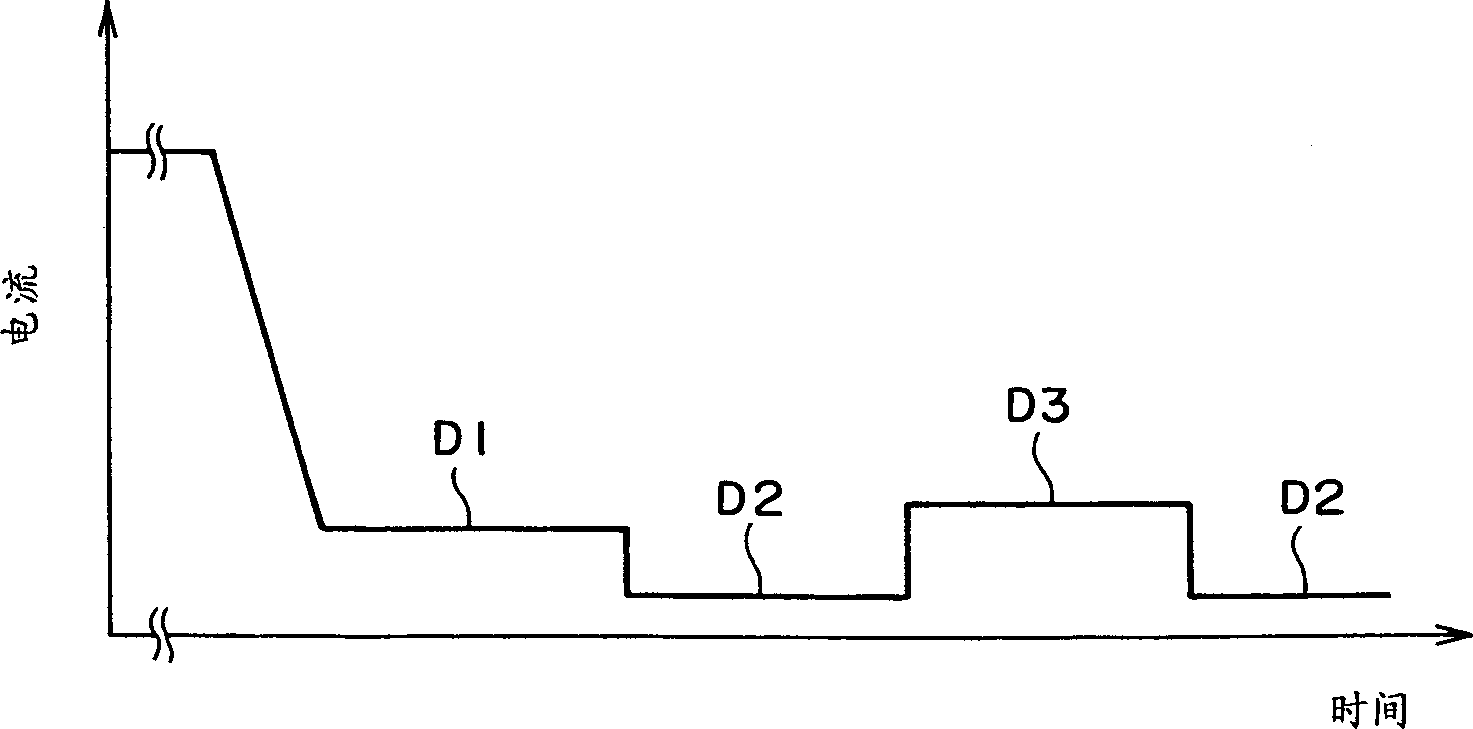

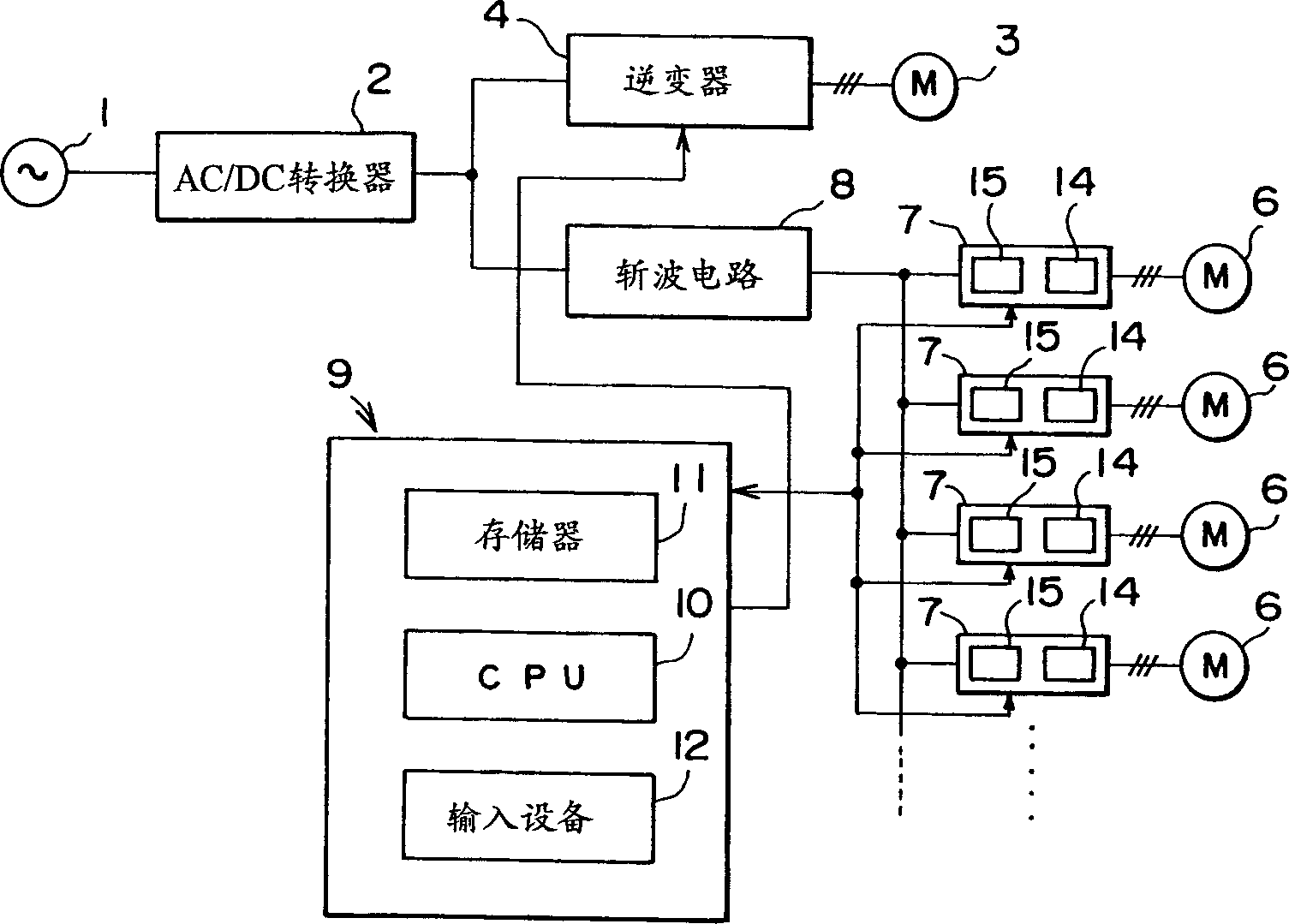

[0017] The following will refer to Figure 1-3 An embodiment of a single-spindle-driven ring spinning machine according to the invention is described.

[0018] Such as figure 2 As shown, an AC power source 1 is connected with an AC / DC converter 2 . A traction motor 3 constituting a traction section drive system is connected to an AC / DC converter 2 through an inverter 4 . The traction section drive system is connected to a hoist drive system (not shown) for synchronous operation. The hoist drive system is used to raise or lower a ring plate and a hook plate angle through a rotary transmission device (not shown), and the traction Motor 3 also drives the lift drive system.

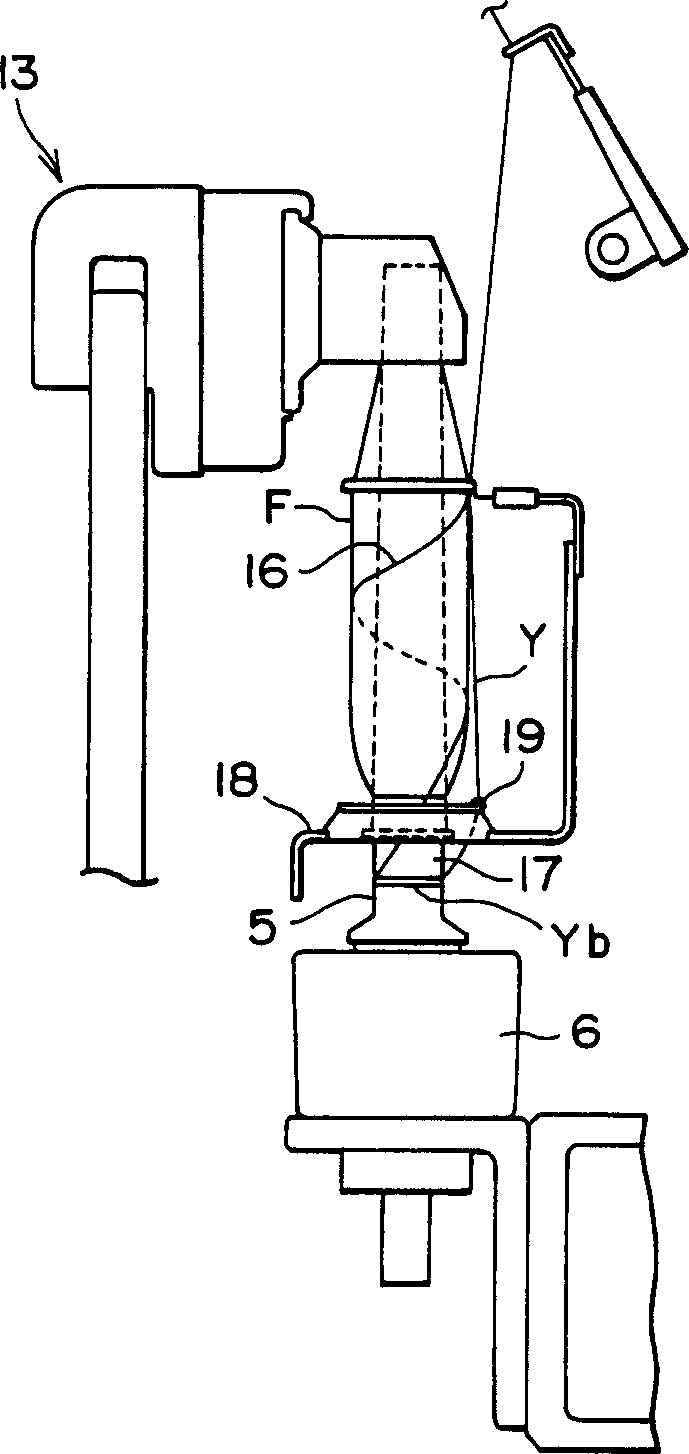

[0019] The respective spindles of the spinning machine are equipped with single spindle drive motors 6 for individually driving each spindle 5 ( image 3 shown). A synchronous motor is used for the single spindle drive motor 6 . In this embodiment, a switched reluctance motor (SR motor) is used. The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com