Process for synthesizing mesoporous SiO2 melecular sieve with cubic structure

A technology of mesoporous silica and synthesis method, which is applied in molecular sieves and base exchange compounds, chemical instruments and methods, crystalline aluminosilicate zeolites, etc., and can solve problems such as failure to synthesize cubic molecular sieves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

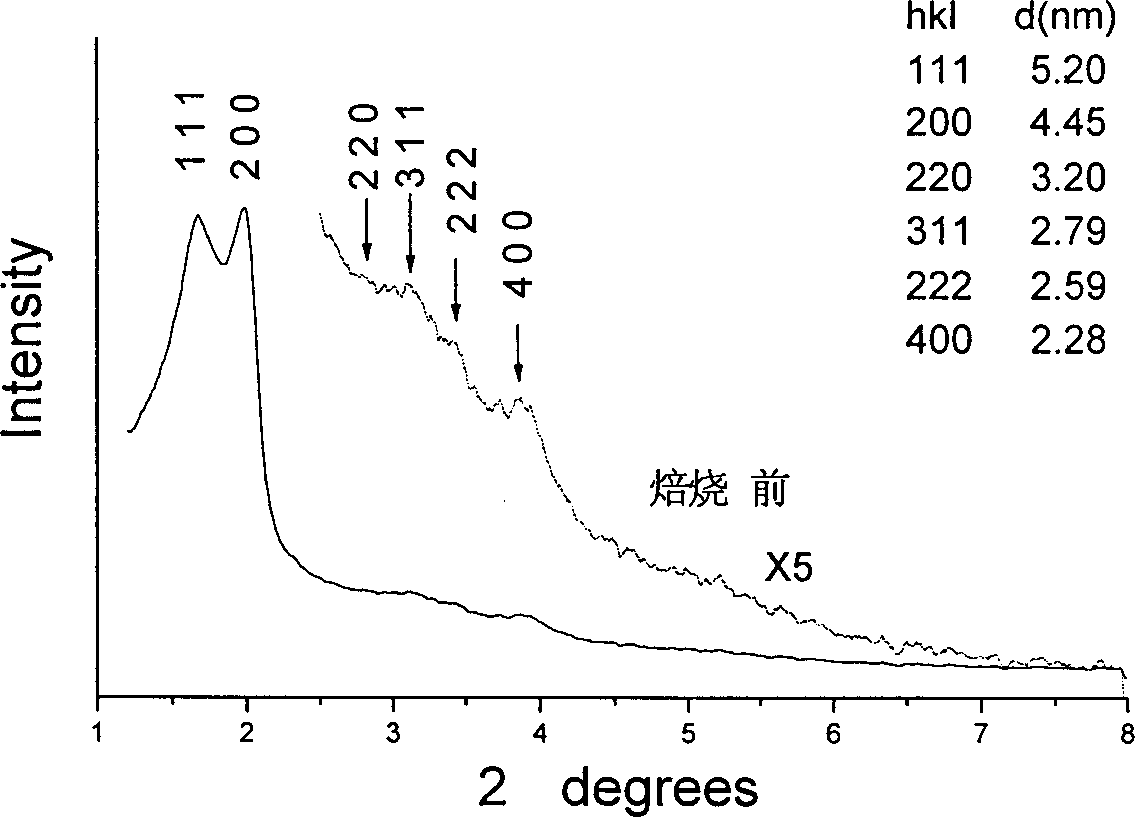

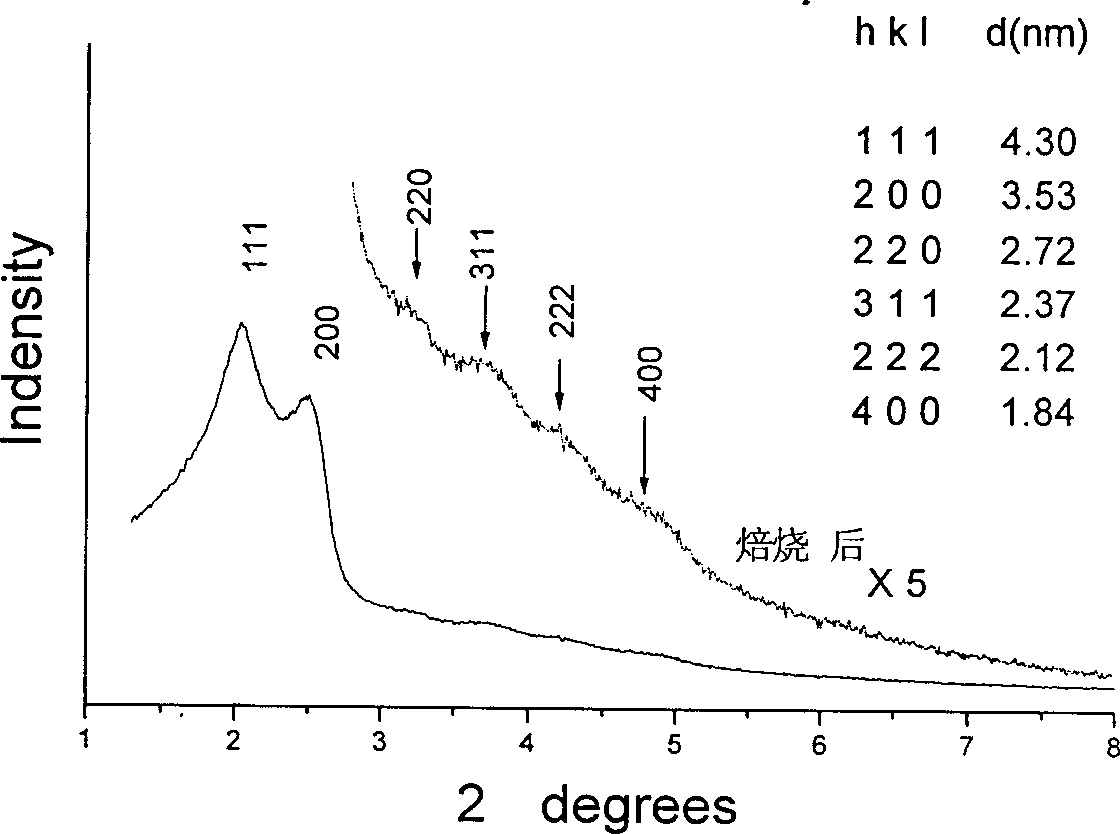

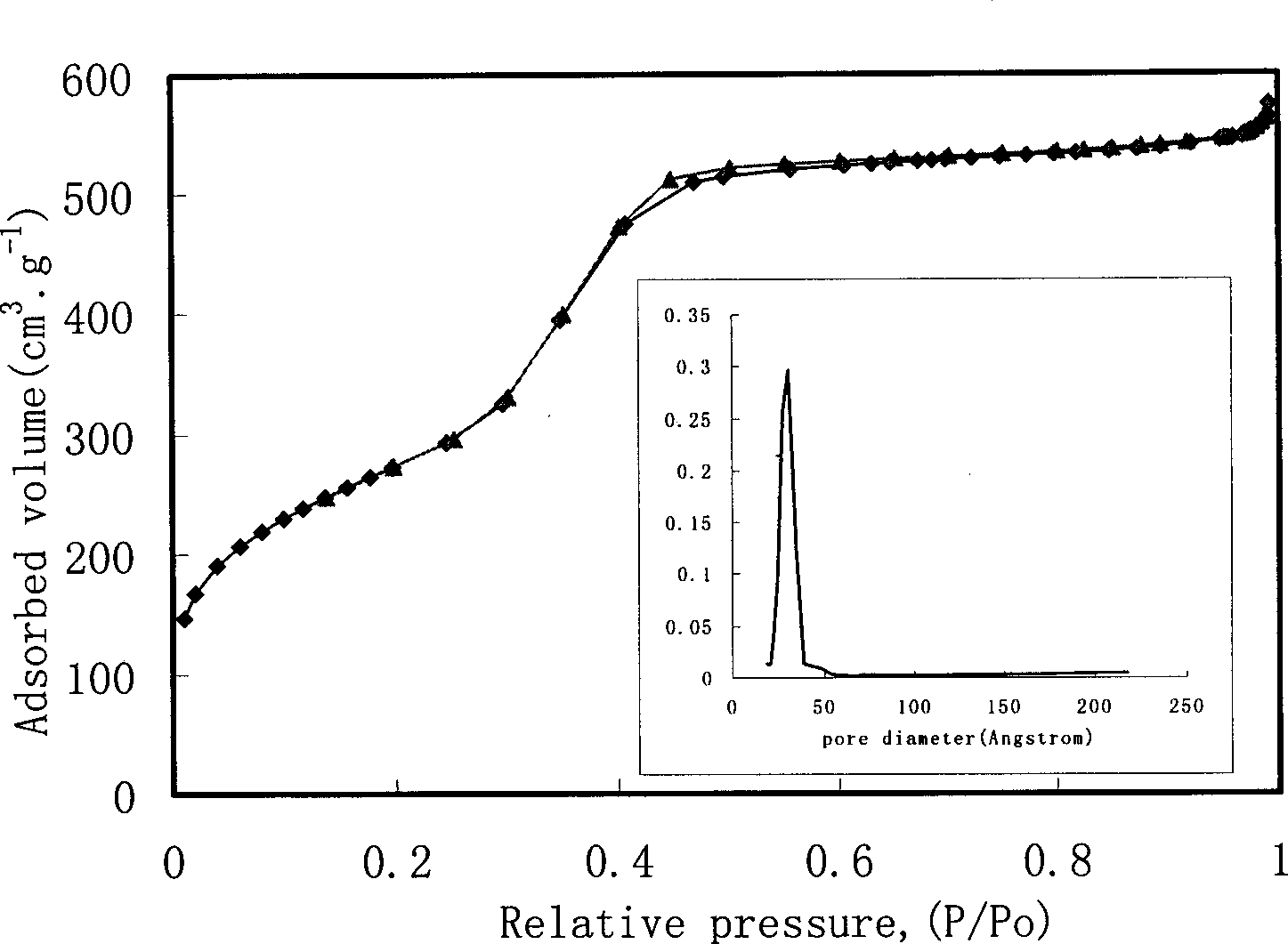

[0013] Example 1, 3g CH 3 (CH 2 ) 16 CH 2 N + (CH 3 ) 2 CH 2 CH 2 N + (CH 3 ) 2 CH 2 CH 2 CH 2 N + (CH 3 ) 3 ·3Br - Dissolve in 120g water, add 48g 0.5MolL -1 Add 8g TEOS (tetraethyl orthosilicate) after stirring evenly, and the molar ratio of the three-head quaternary ammonium salt cationic surfactant, water, sodium hydroxide and tetraethyl orthosilicate is: 0.11: 241.6: 0.625 : 1. The reaction temperature was 18°C. After continuous stirring for 3 hours, the mixture was filtered, washed with deionized water until neutral, dried at room temperature and calcined at 500°C for 4 hours. The position of the diffraction peak 2θ was measured by XRD (X-ray diffraction), and the position index of the diffraction peak 2θ was confirmed to be an Fd3m cubic phase structure. The samples were observed with a TEM (transmission electron microscope). XRD spectrum and TEM photos see Figure 1-Figure 4 . The unit cell parameter of the product calculated according to the d ...

Embodiment 2

[0014] Example 2, 12g CH 3 (CH 2 ) 16 CH 2 N + (CH 3 ) 2 CH 2 CH 2 N + (CH 3 ) 2 CH 2 CH 2 CH 2 N + (CH 3 ) 3 ·3Br - Dissolve in 370g water, add 29g 0.5Mol L -1 After stirring evenly, add 20g TEOS (tetraethyl orthosilicate), and the molar ratio of three quaternary ammonium salt cationic surfactants, water, NaOH and TEOS is: 0.176:230:0.152:1.0. After continuous stirring for 3 hours, the mixture was filtered, washed with deionized water until neutral, dried at room temperature and calcined at 50°C for 3.5 hours. The position of the diffraction peak 2θ was measured by XRD (X-ray diffraction), and the position index of the diffraction peak 2θ was confirmed to be an Fd3m cubic phase structure. According to the d value on XRD, the unit cell parameter of the product is a=7.36nm, and the BET surface area is 901m 2 g -1 , BJH pore diameter is 2.4nm, pore volume is 1.03cm 3 .g -1 .

Embodiment 3

[0015] Example 3, at a synthesis temperature of 20°C, 2.485g CH 3 (CH 2 ) 16 CH 2 N + (CH 3 ) 2 CH 2 CH 2 N + (CH 3 ) 2 CH 2 CH 2 CH 2 N + (CH 3 ) 3 ·3Br - Dissolve in 1500g water, add 660g aqueous solution of 2.24g potassium hydroxide, stir evenly, add 83.3g TEOS. The molar ratio of the three-head quaternary ammonium salt cationic surfactant, water, KOH and TEOS is: 0.088:300:1.0:1.0. After continuous stirring for 3 hours, the mixture was filtered, washed with deionized water until neutral, dried at room temperature and calcined at 500°C for 4 hours. The position of the diffraction peak 2θ was measured by XRD (X-ray diffraction), and the position index of the diffraction peak 2θ was confirmed to be an Fd3m cubic phase structure. According to the d value on the XRD, the unit cell parameter of the product is a=7.73nm, and the BET surface area of the product is 951m 2 g -1 , BJH pore diameter is 2.7nm, pore volume is 0.90cm 3 .g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com