Full two dimension gas phase chromatography modulator

A two-dimensional gas chromatography and modulator technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of poor modulation effect of low boiling point substances, non-repetitive retention time, affecting furnace temperature stability, etc., to achieve equipment investment and the effect of low operating cost, easy availability, and guaranteed reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Example 1. Sample injection peak broadening σ of external modulator i

[0042] Modulator injection peak broadening is an important indicator for evaluating the performance of the modulator. As mentioned above, column 2 is a fast analytical column and needs to be separated within one cycle (1-10 seconds) to avoid overlapping with the separation of the second cycle. Therefore, the broadening of the injection peak will directly lead to the broadening of the second-dimensional peak, and ultimately affect the second-dimensional separation ability.

[0043] The total peak broadening of the second-dimensional analysis component (σ i ) Consists of three parts [Reference 5]:

[0044] σ t 2 = σ i 2 + σ c 2 + σ d 2 - - - 1 ...

Embodiment 2

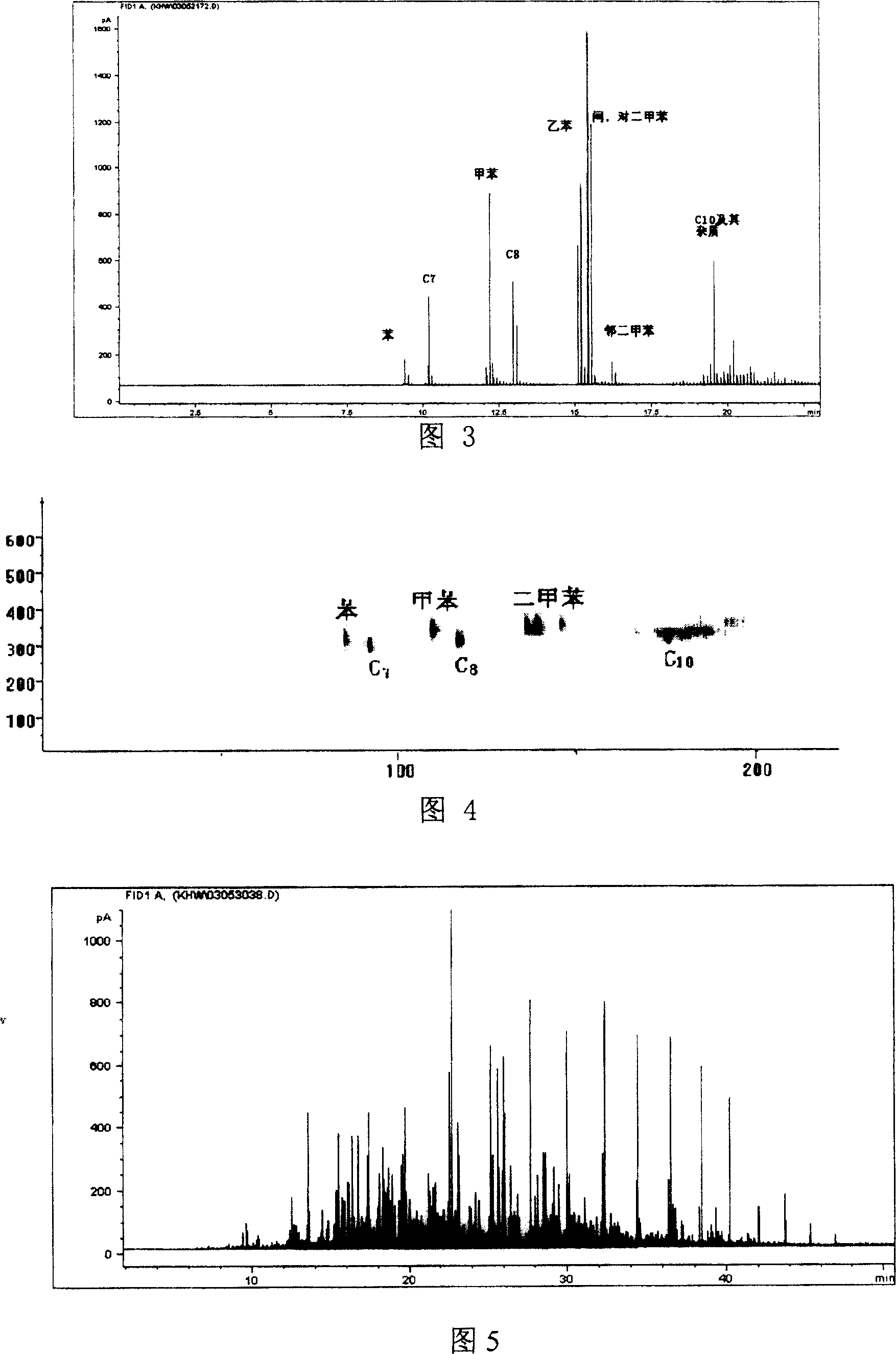

[0067] Example 2. External modulator used for comprehensive two-dimensional gas chromatography to analyze triphenyl and C 7 , C 8 , C 10

[0068] Test conditions: The self-edited software GCXGC workstation is used to process the full two-dimensional spectrum;

[0069] Analysis conditions:

[0070] Chromatographic column: column 1 DB-5 30m×0.25mm×0.5μm (J&W, USA)

[0071] Column 2 DB-17011.75m×0.10mm×0.10μm (J&W, USA)

[0072] Vaporization chamber: 280°C; hydrogen flame detector: 250°C;

[0073] Split ratio 30:1; carrier gas: constant flow of helium (198kPa);

[0074] Column temperature: 35℃(1)→15℃ / min→250℃;

[0075] Sample: Triphenyl and C 7 , C 8 , C 10 ;

[0076] Modulation tube: 1m×0.25mm empty capillary column; auxiliary heater: 30℃ higher than furnace temperature;

[0077] Cold bath: water / ice 0℃; CO 2 The pressure is 7.0Mpa; the nozzle is 3.

[0078] The pulse period is 6.5 seconds; the rest are the same as in embodiment 1;

[0079] After modulation, triphenyl and C 7 , C 8...

Embodiment 3

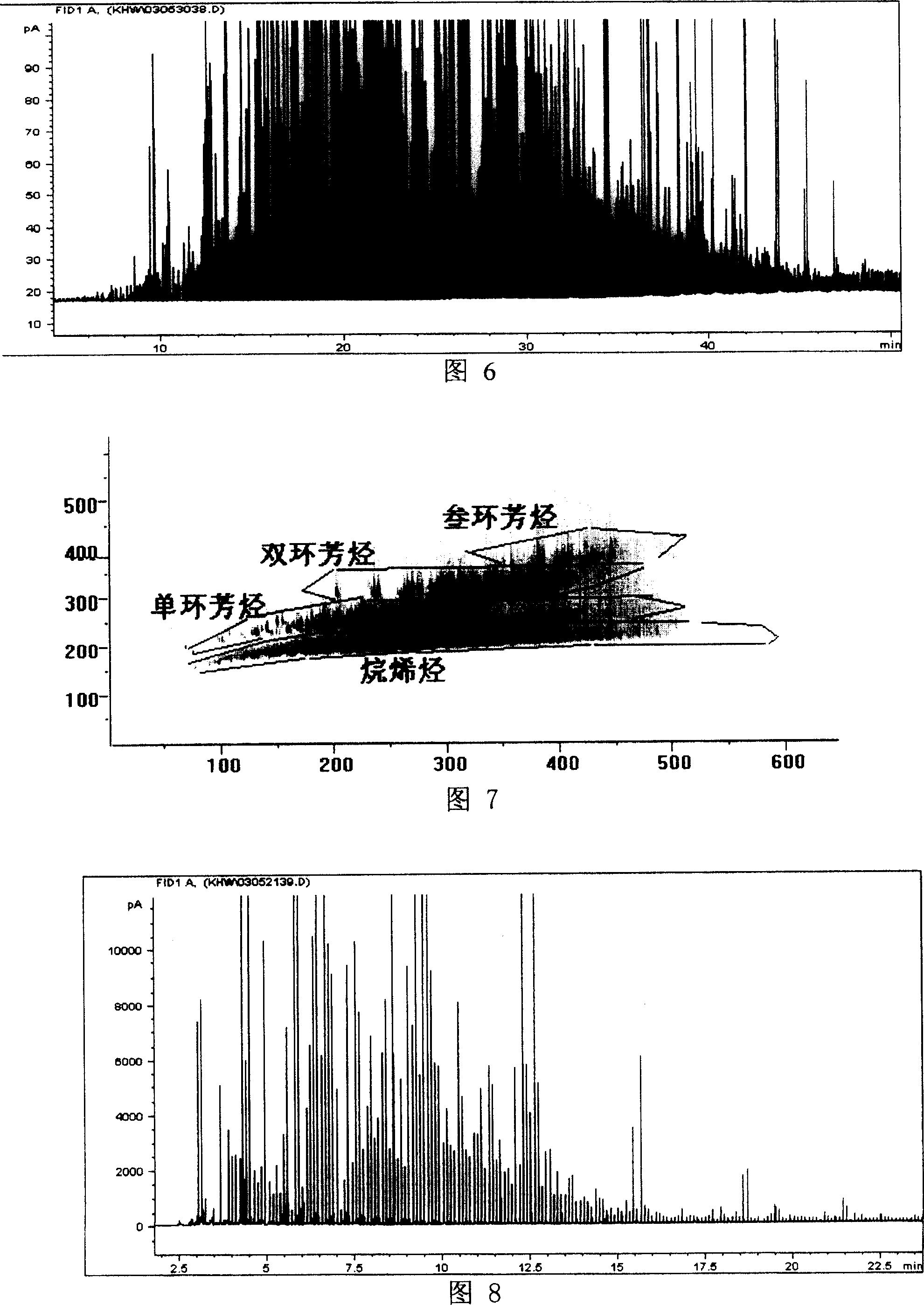

[0080] Example 3. External modulator used for comprehensive two-dimensional gas chromatography analysis of light diesel oil (Sinopec Shanghai Gaoqiao Branch Refinery Catalytic Cracking Diesel)

[0081] Test conditions: same as Example 2

[0082] Analysis conditions: sample: catalytic cracking diesel;

[0083] Carrier gas: constant flow of helium (150kPa);

[0084] Column temperature: 35℃(1)→5℃ / min→270℃;

[0085] Auxiliary heater: synchronized with furnace temperature rise;

[0086] Modulation tube: 2m×0.175mm empty capillary column;

[0087] Cold bath: water / ethanol / dry ice -7℃; CO 2 The pressure is 3.5Mpa; nozzle 5.

[0088] The pulse period is 5.8 seconds; the rest is the same as in embodiment 2;

[0089] The comprehensive two-dimensional chromatographic separation diagram of the modified catalytic cracking diesel is shown in Figure 5, and the enlarged comprehensive two-dimensional chromatographic separation diagram is shown in Figure 6. The comprehensive two-dimensional chromat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com