Electric connector and manufacturing method thereof

A technology for electrical connectors and manufacturing methods, applied in the field of electrical connectors and their manufacturing, capable of solving problems such as difficult assembly, high cost, and complicated processing steps, and achieving the effects of convenient processing, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

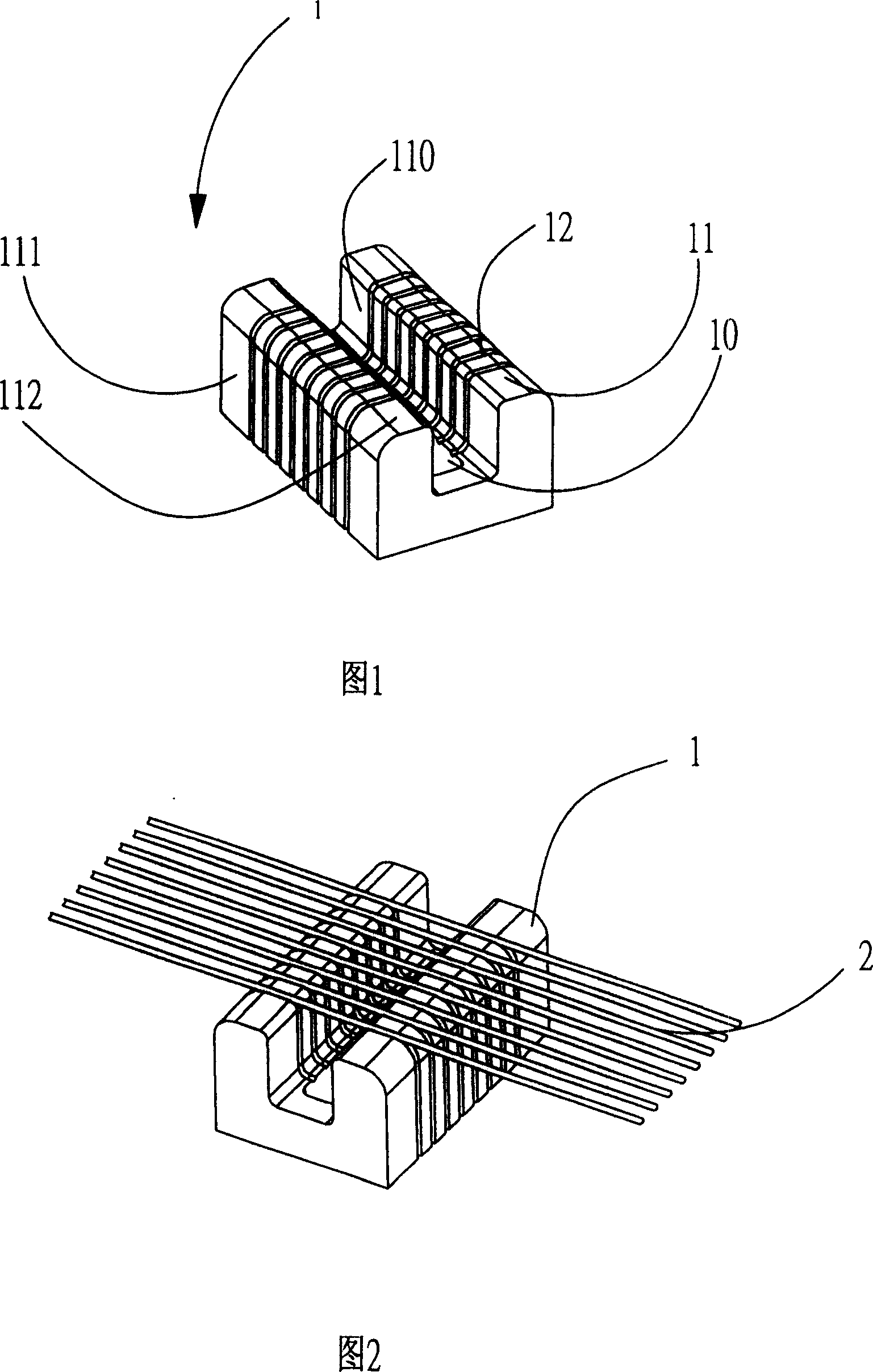

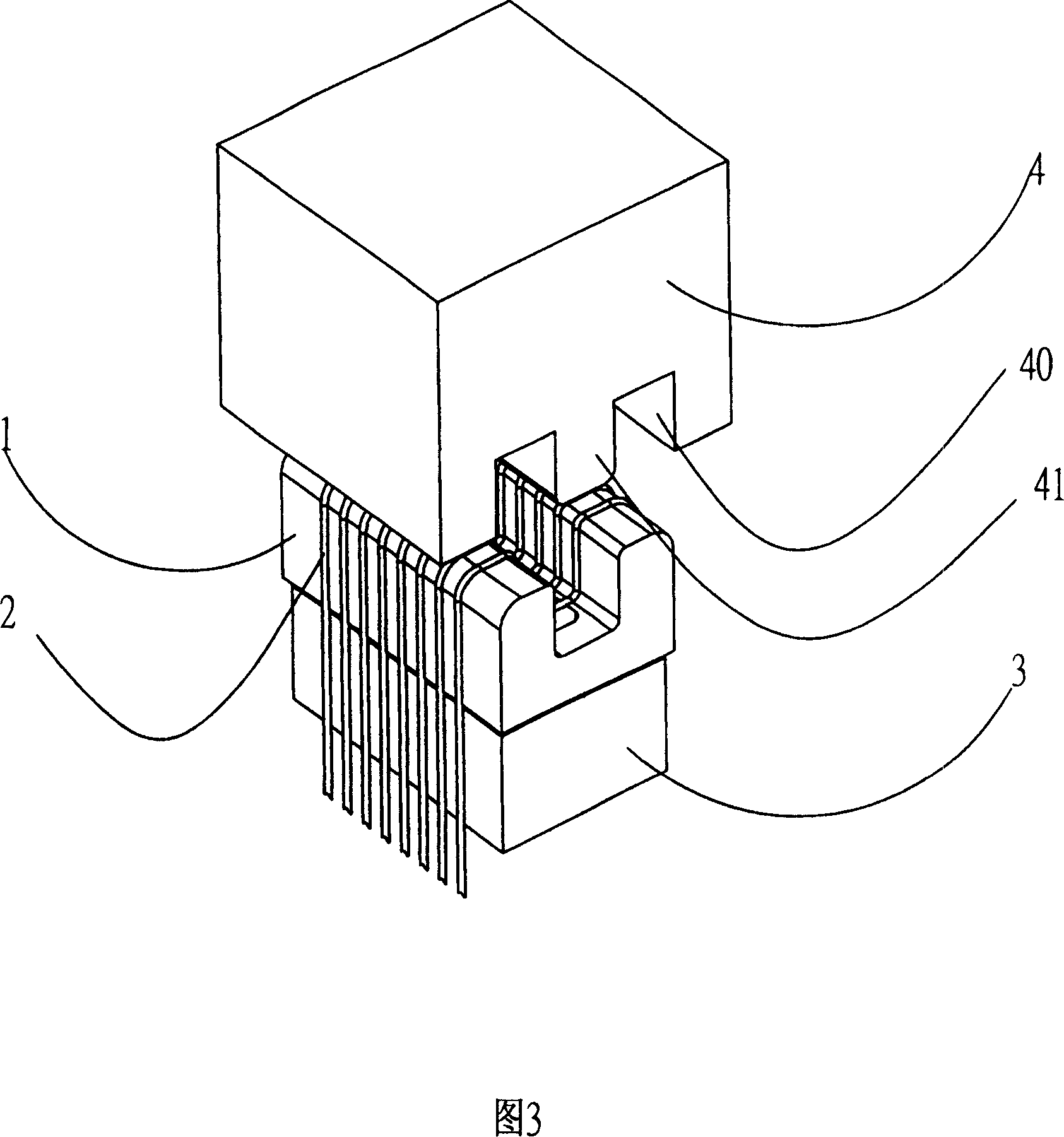

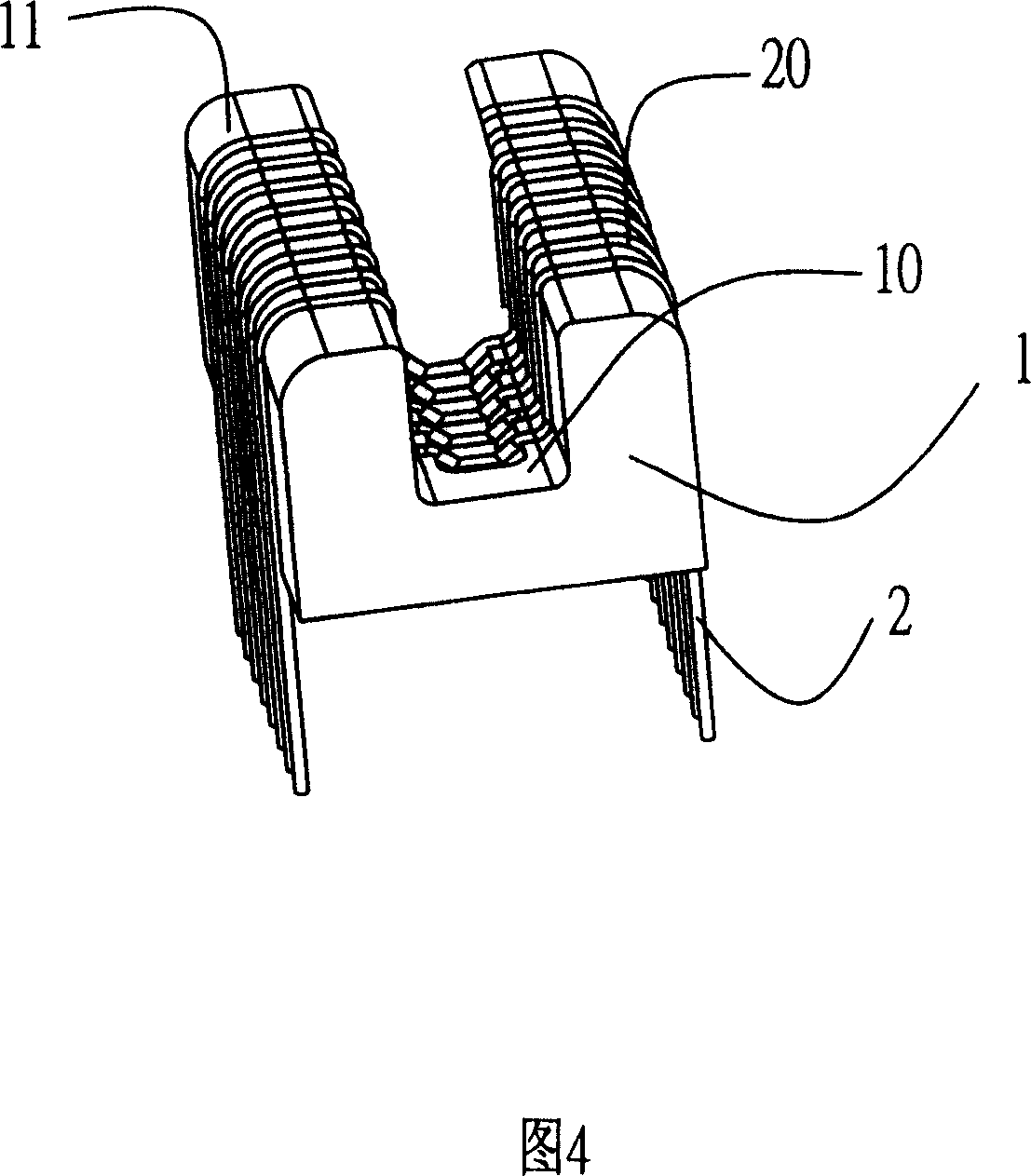

[0017] 1 to 4, the electrical connector of the present invention includes an insulator 1 and a plurality of metal wires 2, wherein a groove 10 is provided in the middle of the insulator 1, side walls 11 are provided on both sides of the groove 10, and the inner and outer sides of the side wall 11 are The sides 110, 111 and the top 112 are provided with grooves 12, and the metal wires 2 are correspondingly embedded in the grooves 12 of the insulator 1, and are bent and formed. The width of at least a part of the grooves 12 is smaller than the width of the metal wires 2, so that the metal The wire 2 is fixed in the insulator 1, at least a part of the metal wire 2 protrudes from the surface of the insulator 1 to form a contact area 20, which can form an electrical connection with an external component (not shown in the figure), and the two ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com