Brushless motor and sealed compressor having same

A technology of brushless motor and manufacturing method, applied in machine/engine, manufacturing motor generator, synchronous motor with stationary armature and rotating magnet, etc. Compressor miniaturization and other issues, to achieve the effect of expanding the winding area, good shapeability, and increasing the amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Various embodiments of the present invention will be described below with reference to the accompanying drawings 1 to 13 .

[0041] (Embodiment 1)

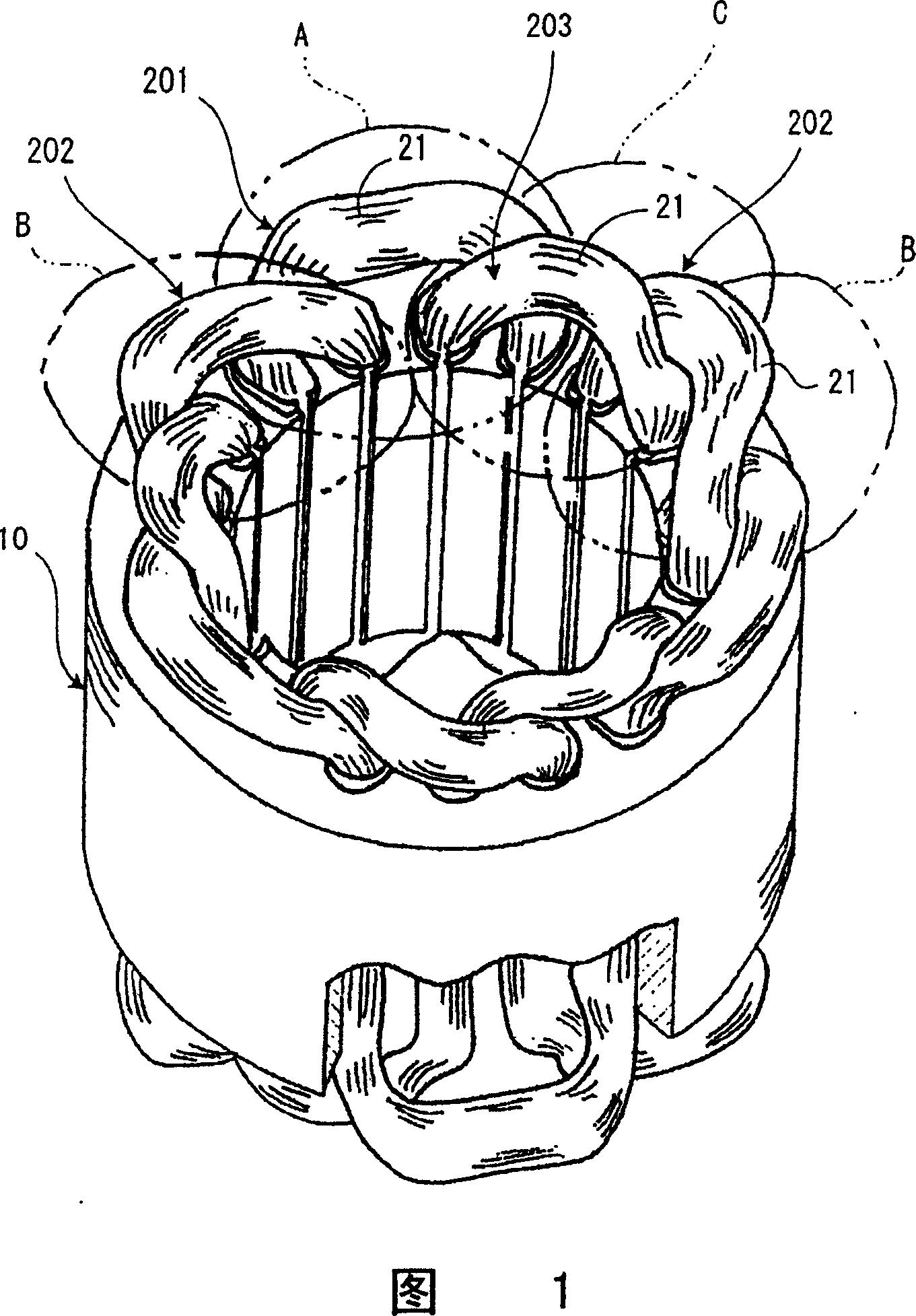

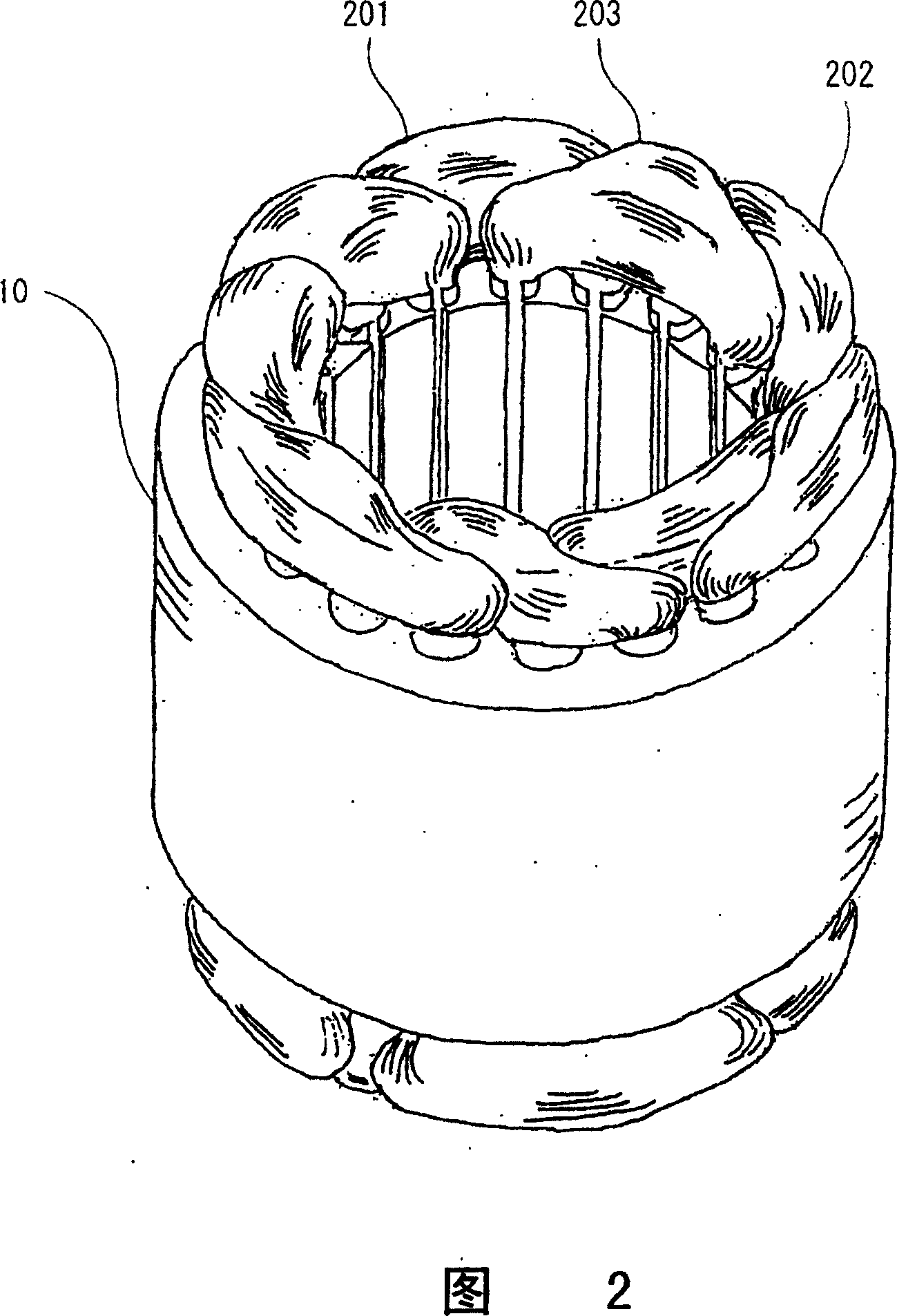

[0042] FIG. 1 shows the coil arrangement of the stator of a three-phase full-segment winding brushless motor with 6 poles in the rotor and 18 slots in the stator.

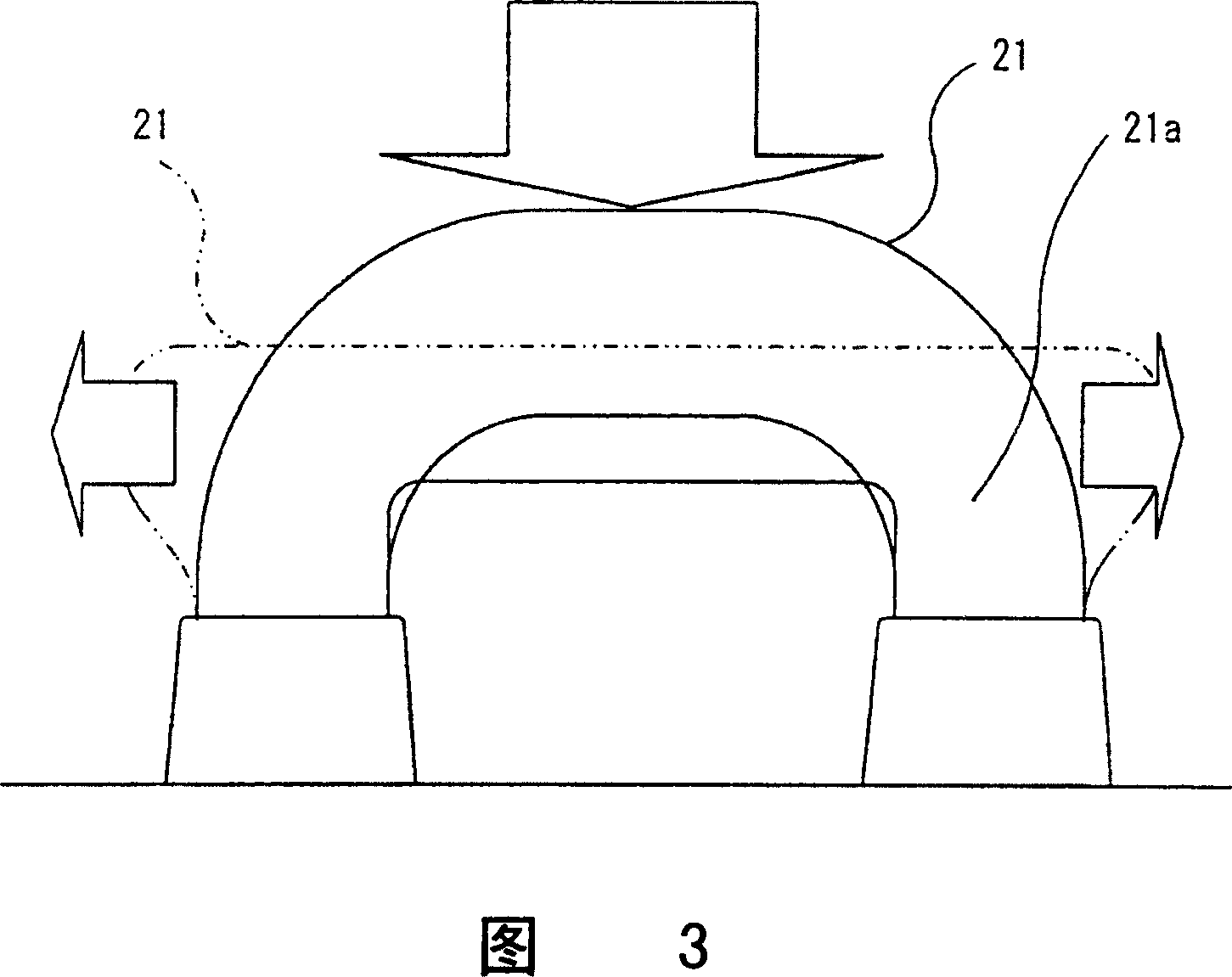

[0043] The end faces of the coils of each phase on the end face of the stator core are arranged at positions where they are inserted into slots where the second coil 202 and the third coil 203 are adjacent to each other (hereinafter referred to as "A part", corresponding to the symbol "A" in FIG. 1 ). ), the first coil 201 is disposed on the outside of the second coil 202 and the third coil 203, and is inserted into the slot where the first coil 201 and the third coil 203 are adjacent to each other (hereinafter referred to as "part B", as shown in Fig. 1 Corresponding to the symbol "B" in ), the second coil 202 is arranged on the inner side of the first coil 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com