Sintered artificial decoration plate

A decorative board and man-made technology, which is applied in building construction, covering/lining, construction, etc., can solve the problems of floor exposure, chipped edge decoration, unsightly appearance, etc., and achieve the effect of convenient purchase and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

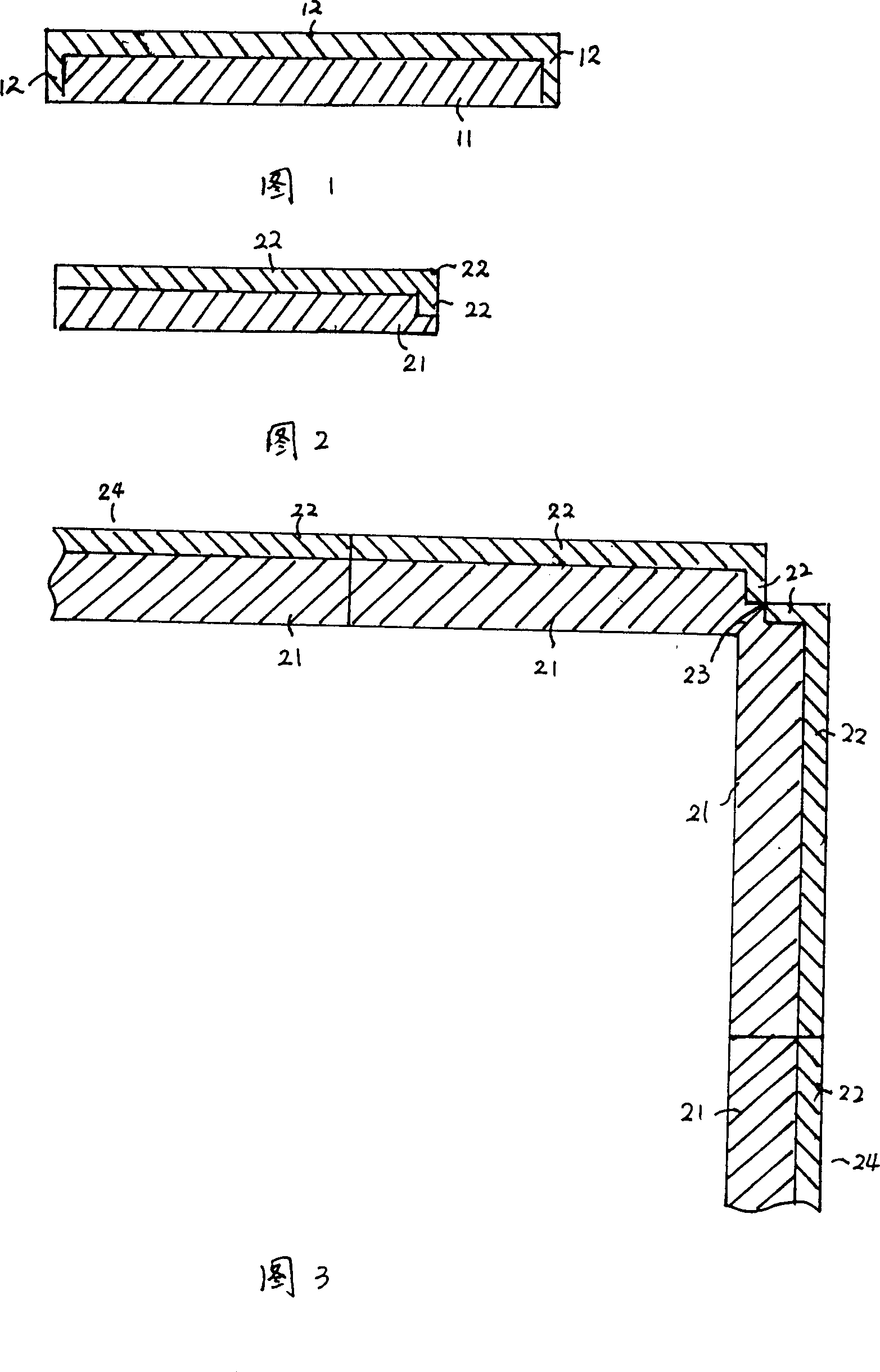

[0020] Refer to Figure 1. The present invention includes a substrate 11 and a decoration layer 12, which has four sides and is rectangular. The decoration layer extends to all sides of the board and covers all the sides of the substrate.

[0021] Figure 1 shows the decorative layers on two sides, and the situation on the other two sides is the same as the two sides shown in the figure.

Embodiment 2

[0023] Refer to Figures 2 and 3. The present invention includes a substrate 21 and a decoration layer 22. The decoration layer extends to one side of the board without covering all the sides of the substrate.

[0024] The inscribing starts from the starting position 23 where the substrate is exposed to the outside. The attached icon number 24 is an ordinary decorative board.

Embodiment 3

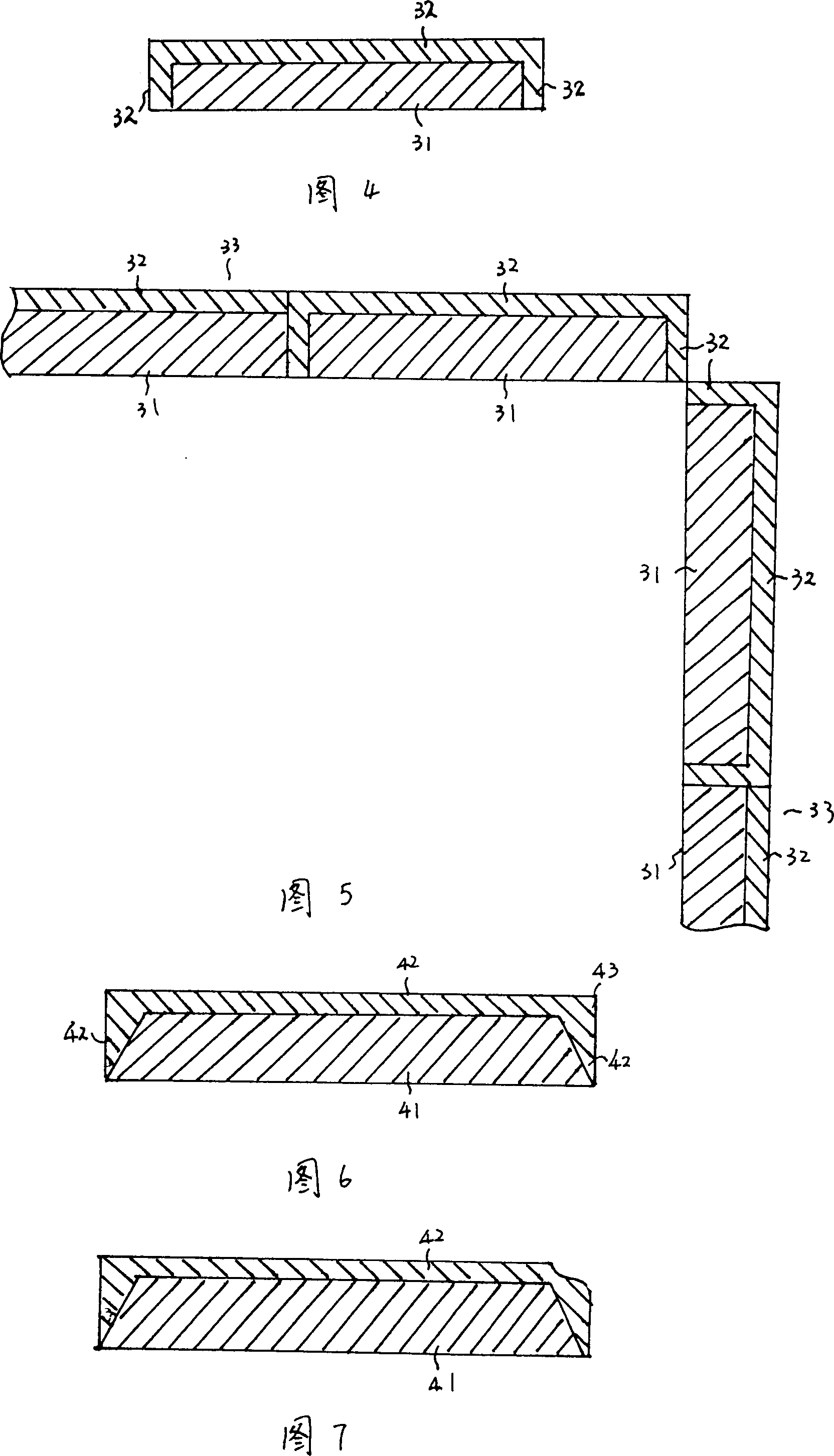

[0026] Refer to Figures 4 and 5. The present invention includes a substrate 31 and a decoration layer 32. It has four sides and is rectangular. The decoration layer extends to the two sides of the board and covers all the sides of the substrate.

[0027] Figure 5 is a schematic diagram of the docking, it does not cut in. The attached symbol 33 is a common decorative board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com