Upflow reactor system with layered catalyst bed for hydrotreating heavy feedstocks

A catalyst layer and heavy raw material technology, applied in the field of reactor systems, can solve the problems of high investment at the high pressure port, increased total investment, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention can be easily understood with reference to these drawings.

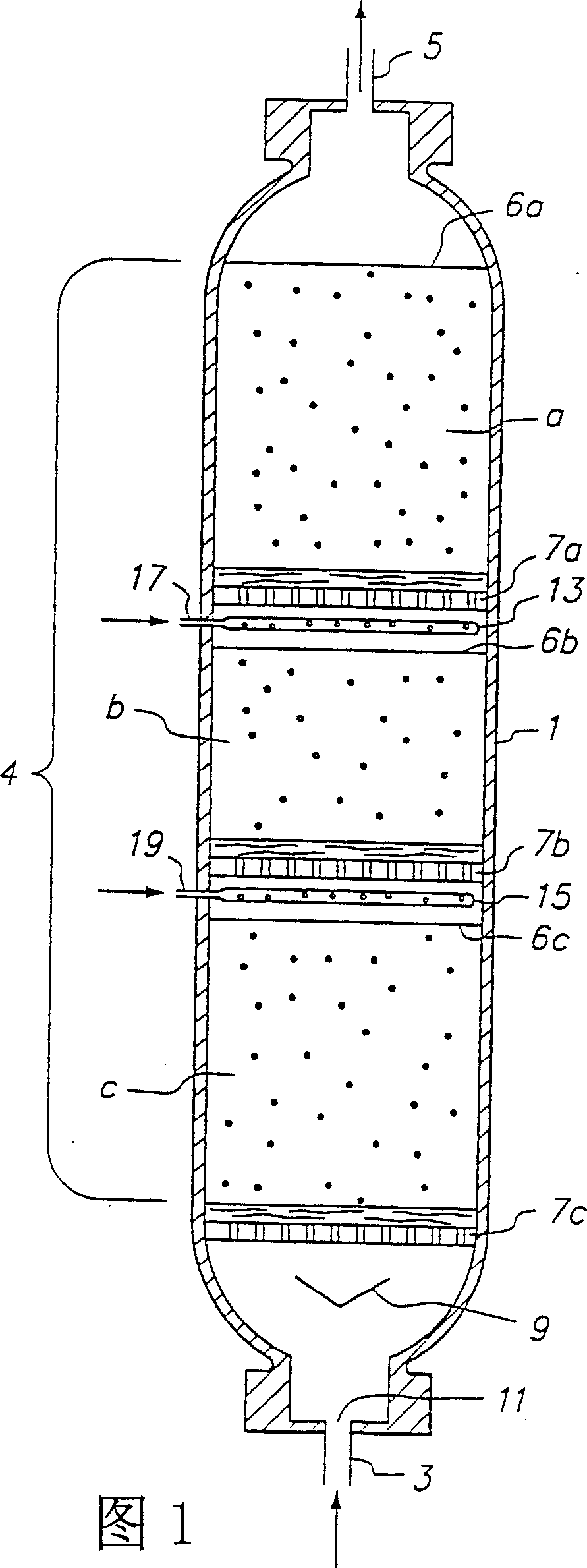

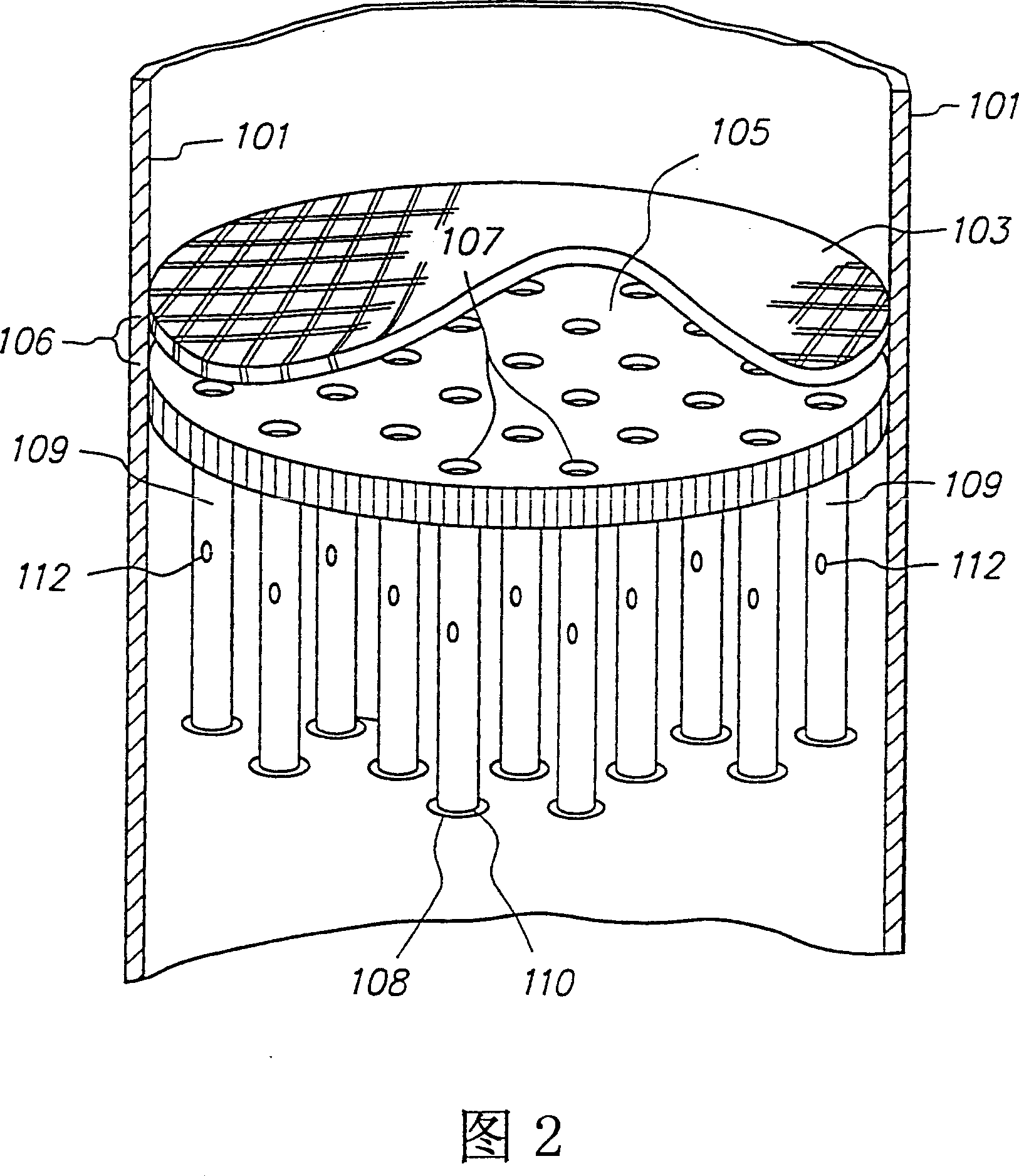

[0027] Figure 1 is a cross-sectional view of one embodiment of the present invention. Hydroprocessing reactor 1 has an inlet conduit 3 for feeding a mixture of heavy feedstock and hydrogen and an outlet conduit 5 for withdrawing a treated product stream along with any excess hydrogen and quench gas or liquid. As shown in this particular embodiment, the catalyst bed 4 is divided into 3 discrete catalyst layers, labeled a, b and c respectively; however, those skilled in the art will appreciate that the number of catalyst layers may be less Up to 2 or more to the number actually required to implement the object of the present invention. In the figures, the top of each discrete catalyst layer is labeled 6a, 6b and 6c, respectively. Each catalyst layer is placed on catalyst support and fluid distribution equipment, for 3 catalyst beds, they are respectively indicated as 7a, 7b and 7c. In th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com