Feeding device, ink jet type image output equipment and control method of transfer speed

An image output and conveying module technology, applied in printing, printing devices, etc., can solve the problems of time waste, high resistance, failure to take paper, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

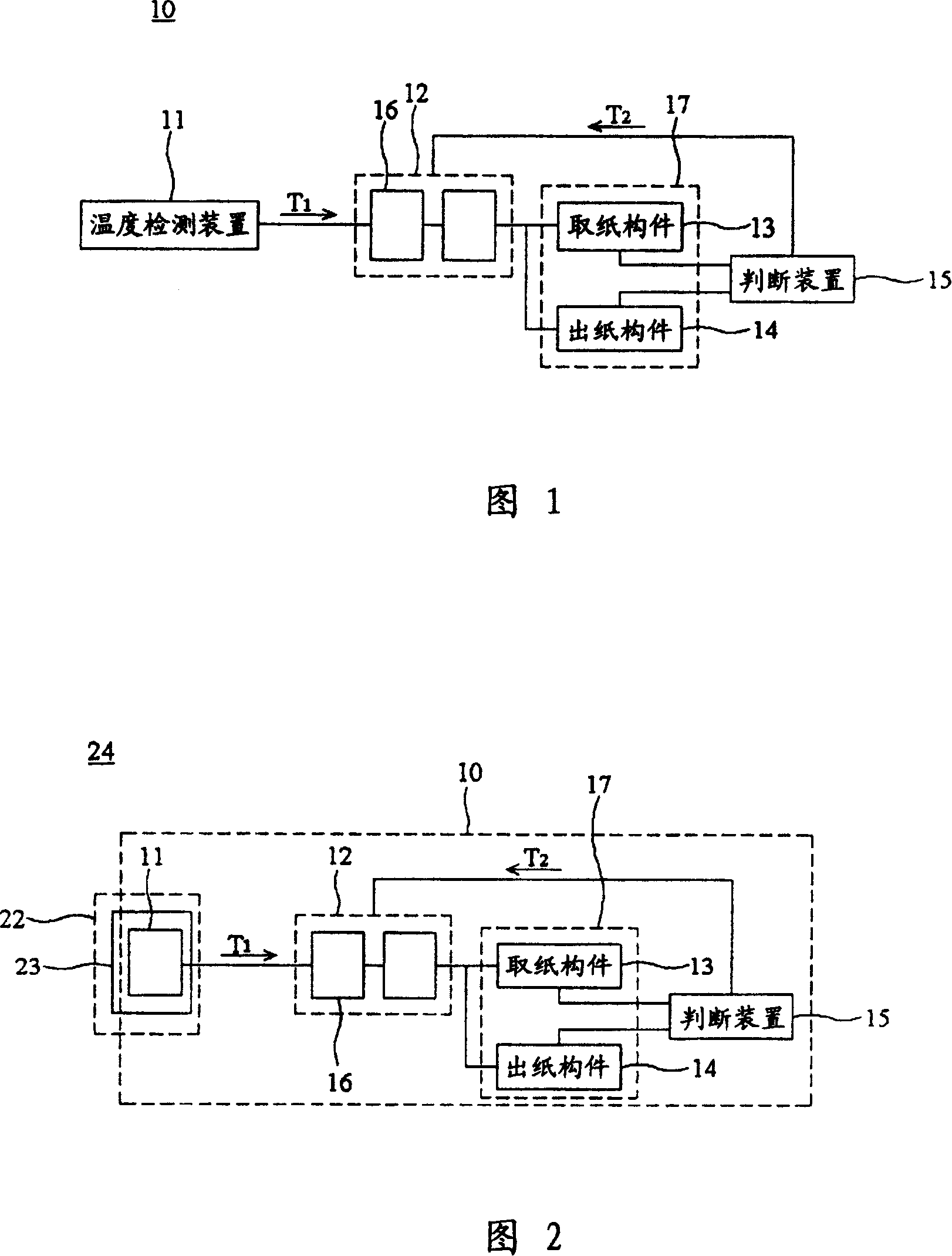

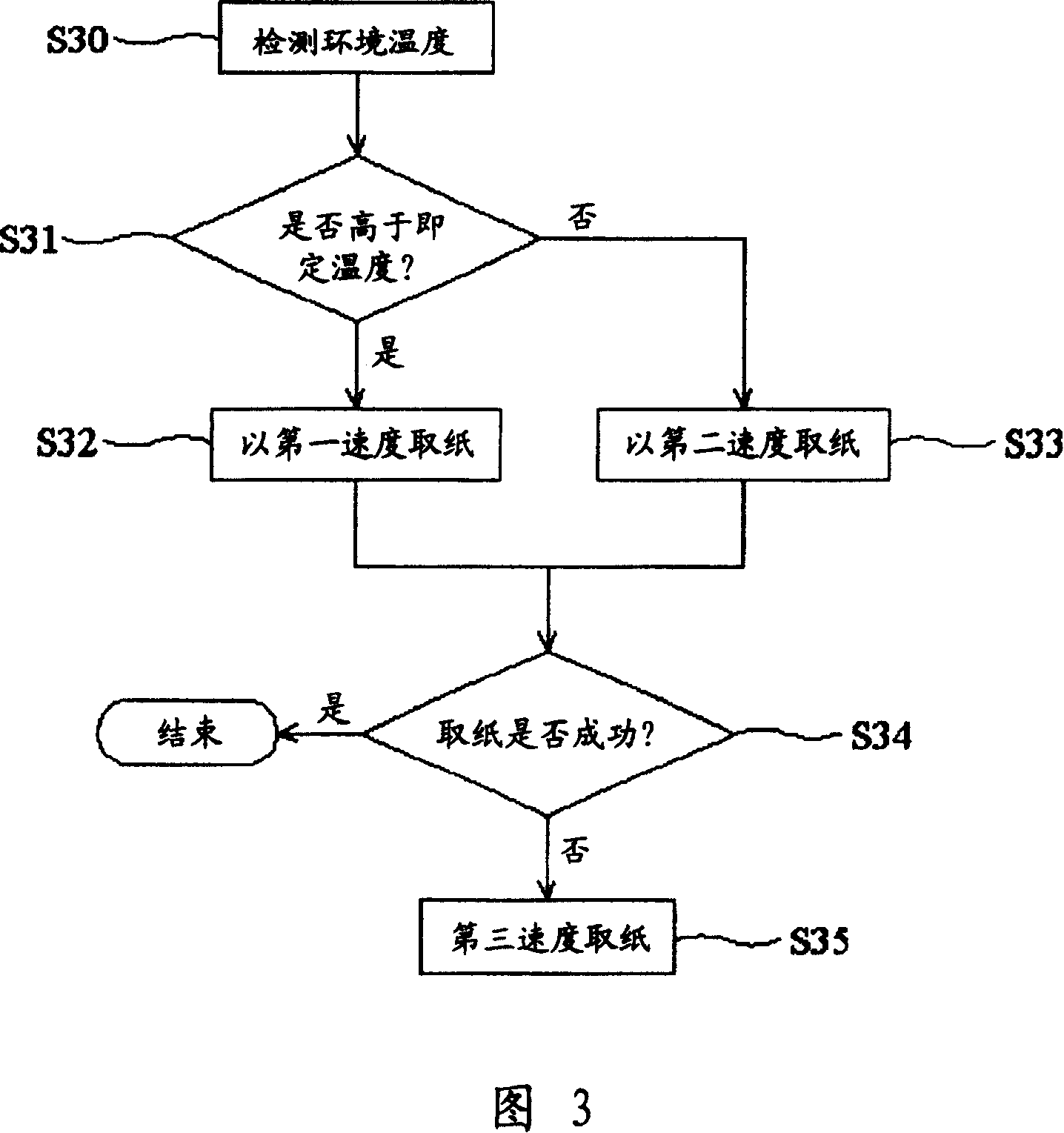

[0025] FIG. 1 shows a block diagram of a delivery module 10 according to an embodiment of the present invention, and the delivery module 10 is suitable for an image output device. The conveying module 10 has a temperature detection device 11 , a control device 12 , a judging device 15 and a conveying member 17 . The transport member 17 includes a paper pick-up member 13 and a paper discharge member 14 .

[0026] The paper-taking member 13 is arranged at the recording medium input place of the image output device, and the recording medium is transported from the recording medium storage place of the image output device to the print work area of the image output device, and the recording medium in the embodiment of the present invention is paper as an example. The temperature detection device 11 detects the ambient temperature before the paper fetching member 13 fetches the paper, and outputs a corresponding temperature signal T1 according to the ambient temperature, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com