Warp knitting machine with at least one stripping comb

A technology of warp knitting machine and floral bar, which is applied in the field of warp knitting machine, can solve problems such as the deformation of the second yarn guide rod, and achieve the effect of increasing life and improving sliding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

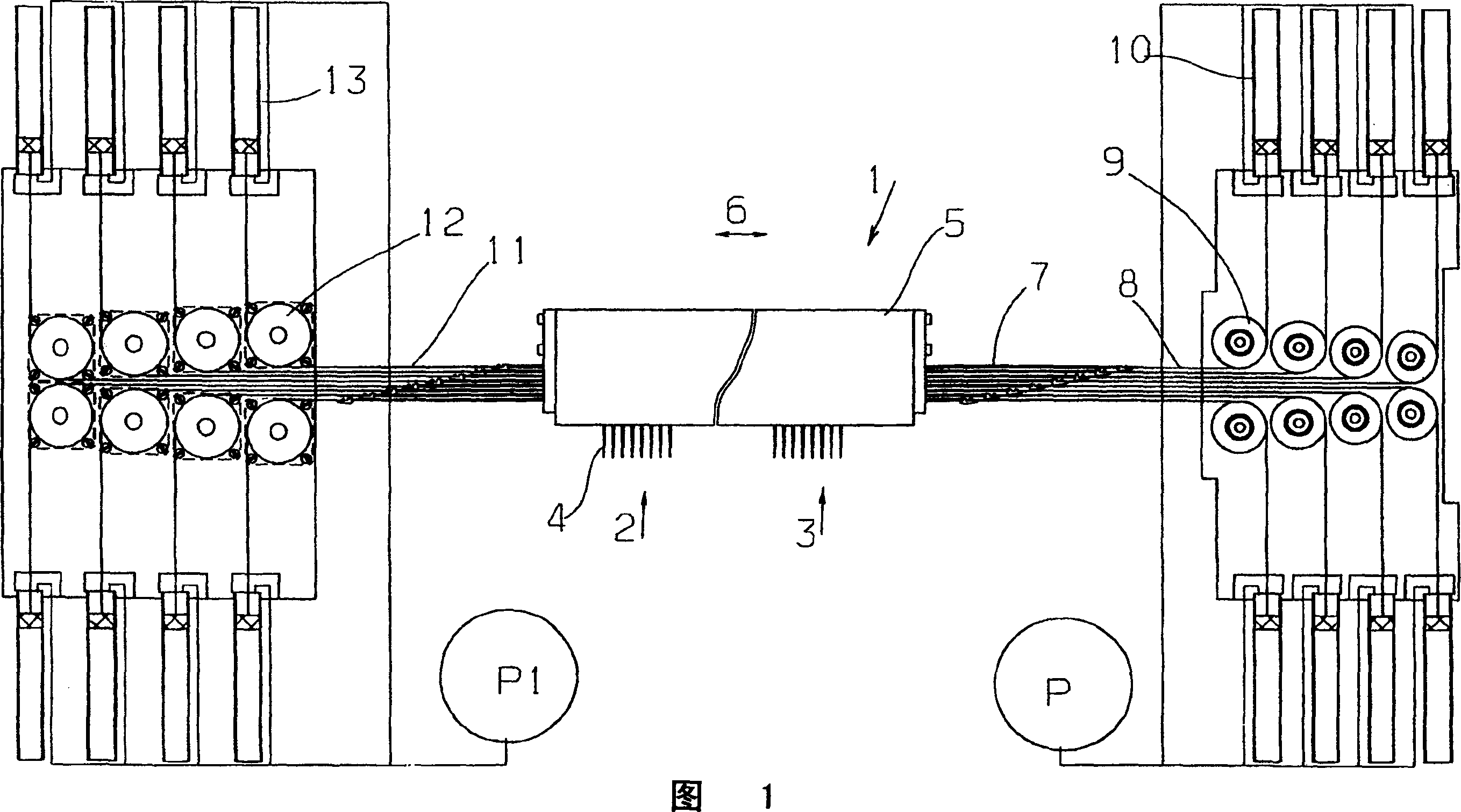

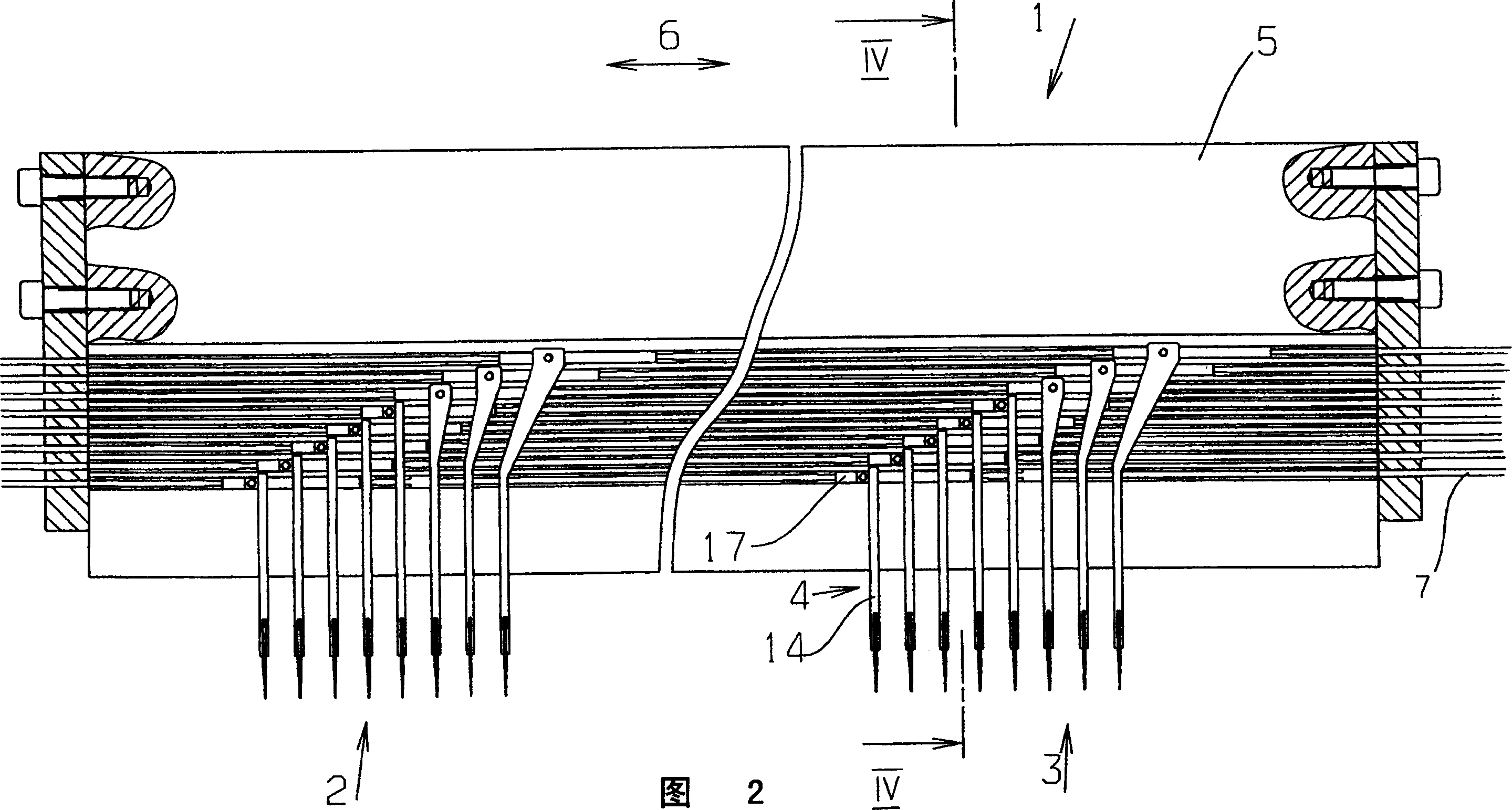

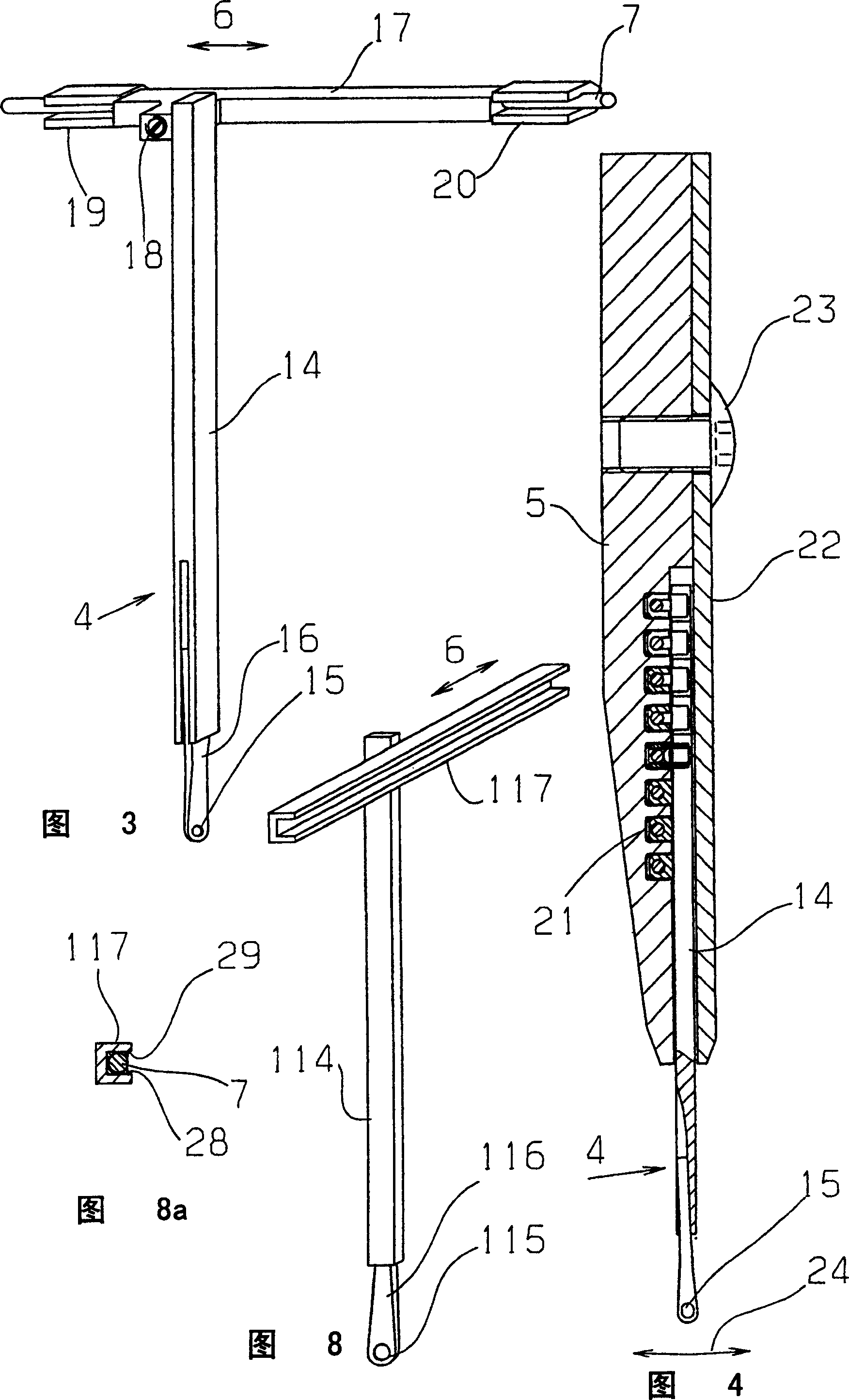

[0034] Fig. 1 shows a flower bar 1 with multiple sets of 2,3 yarn guides 4. The thread guides 4 of each group 2, 3 that are mutually consistent, that is, the first, second, third, etc. thread guides 4 of each group 2, 3 are collectively driven, that is to say, they are relative to the bar holder The frame 5 is movable in a traversing direction 6 indicated by a double arrow, a device (not shown in detail) is provided, by means of which the bar carriage 5 is also movable in the traversing direction 6 .

[0035] For driving the thread guide 4, traction elements 7 are provided, which are of wire or cable construction and therefore have a small cross-section. The traction elements 7 , which will be described in more detail below with reference to FIGS. 2 and 4 , are arranged one above the other perpendicular to the traversing direction. Each traction element 7 is connected to a drive motor 9 via a drive belt 8, wherein the drive belt 8 is fixed at its other end in a tension member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com