Exposure device, exposure method and element making method

A technology of exposure device and manufacturing method, which is applied in the direction of photolithographic process exposure device, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems of pattern segmentation position limitation, size limitation, difficulty, etc., and achieve the goal of improving bonding accuracy and exposure uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

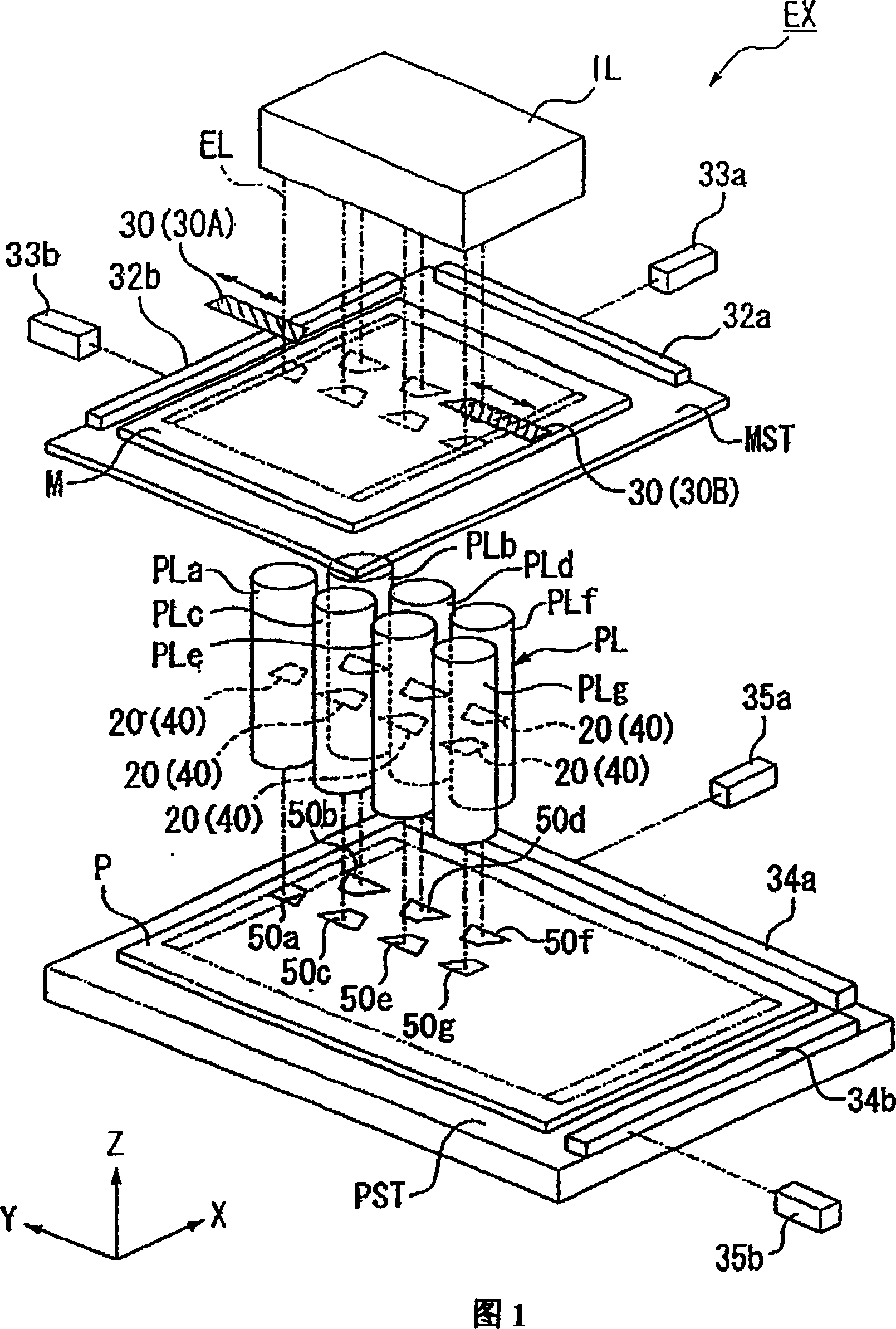

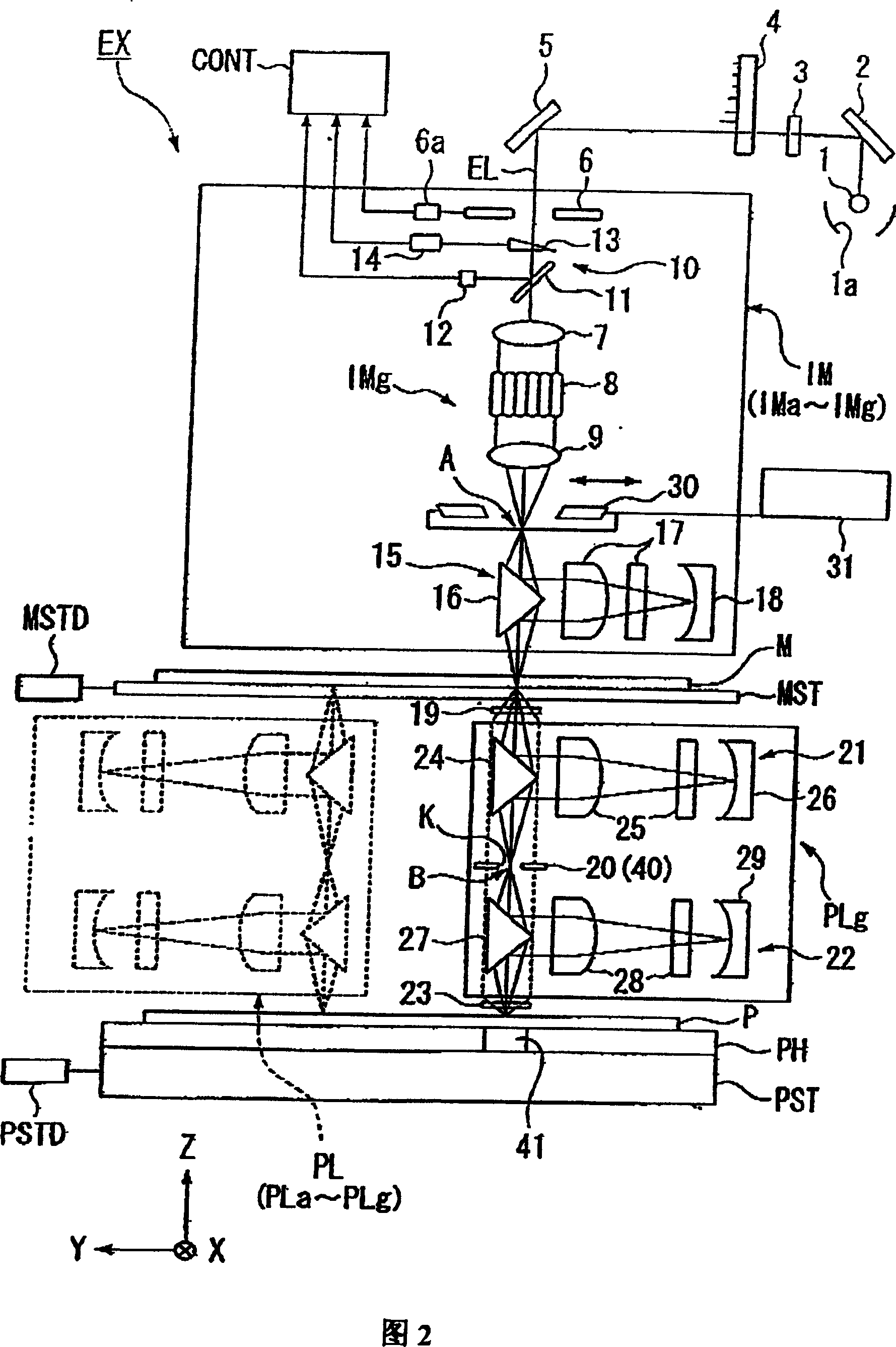

[0062] Hereinafter, the exposure apparatus and the exposure method of this invention, and the manufacturing method of the element are demonstrated with reference to drawing. FIG. 1 is a schematic perspective view of an embodiment of the exposure apparatus of the present invention, and FIG. 2 is a schematic configuration diagram of the exposure apparatus.

[0063] In FIGS. 1 and 2, the exposure device EX includes a mask table MST on which a mask M is placed; and an illumination optical system IL that can emit an exposure (beam) EL to illuminate the mask M on the mask table MST; and a substrate table PST , placing the photosensitive substrate P so as to expose the pattern formed on the mask M; and the projection optical system PL, projecting and exposing the pattern image of the mask M irradiated by the illumination optical system IL on the substrate stage PST. This illumination optical system IL has a plurality (seven in this embodiment) of illumination elements IM (IMa˜IMg). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com