Regular icosahedron titanium-base quasi-crystal material with hydrogen-storage function and its preparing method

A technology of icosahedron and quasicrystal, which is applied in the field of Ti-Zr-Ni-Cu single icosahedral quasicrystal material and its preparation, can solve problems such as production and application difficulties, achieve excellent hydrogen absorption performance, and facilitate industrial chemical, high electrochemical discharge capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

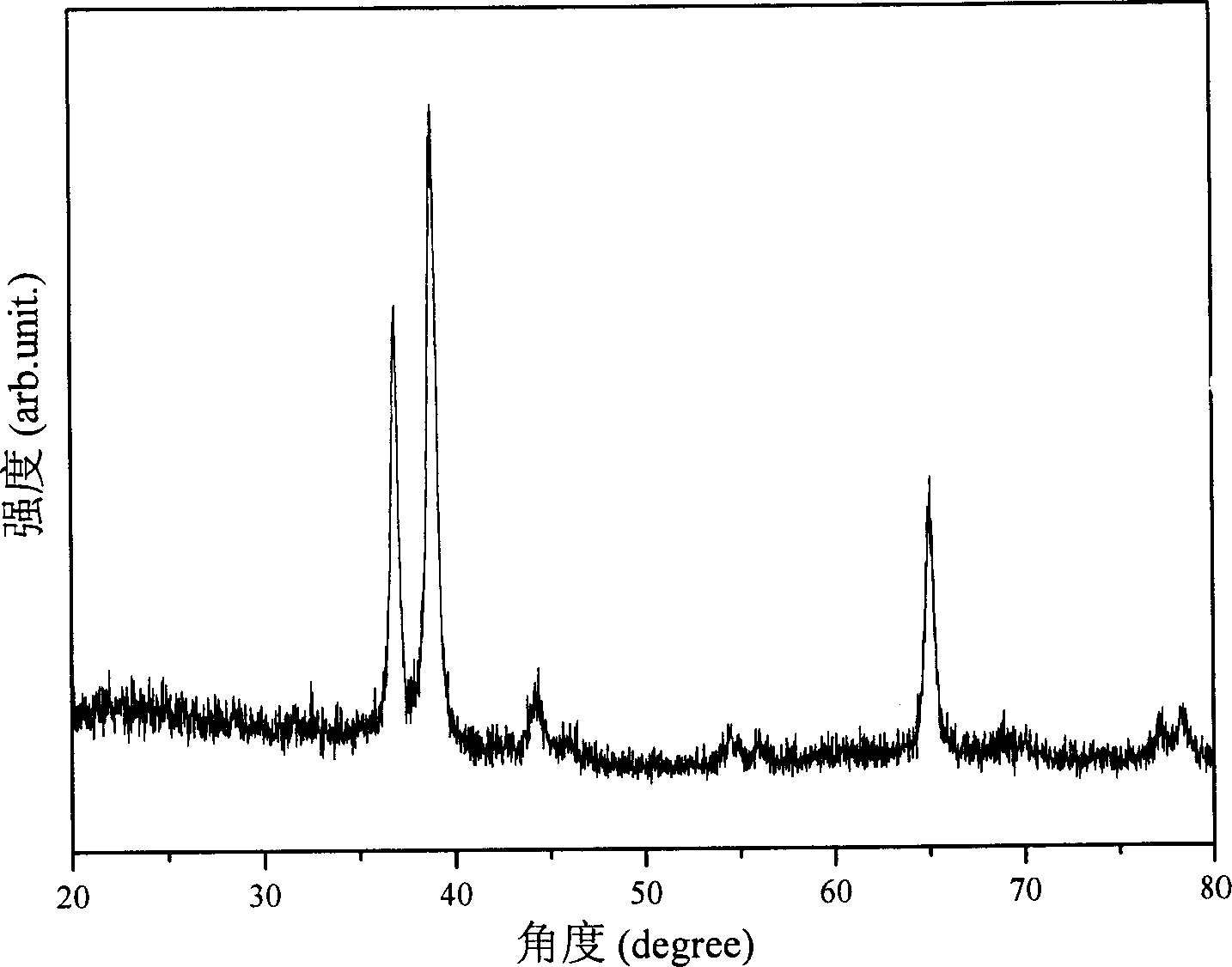

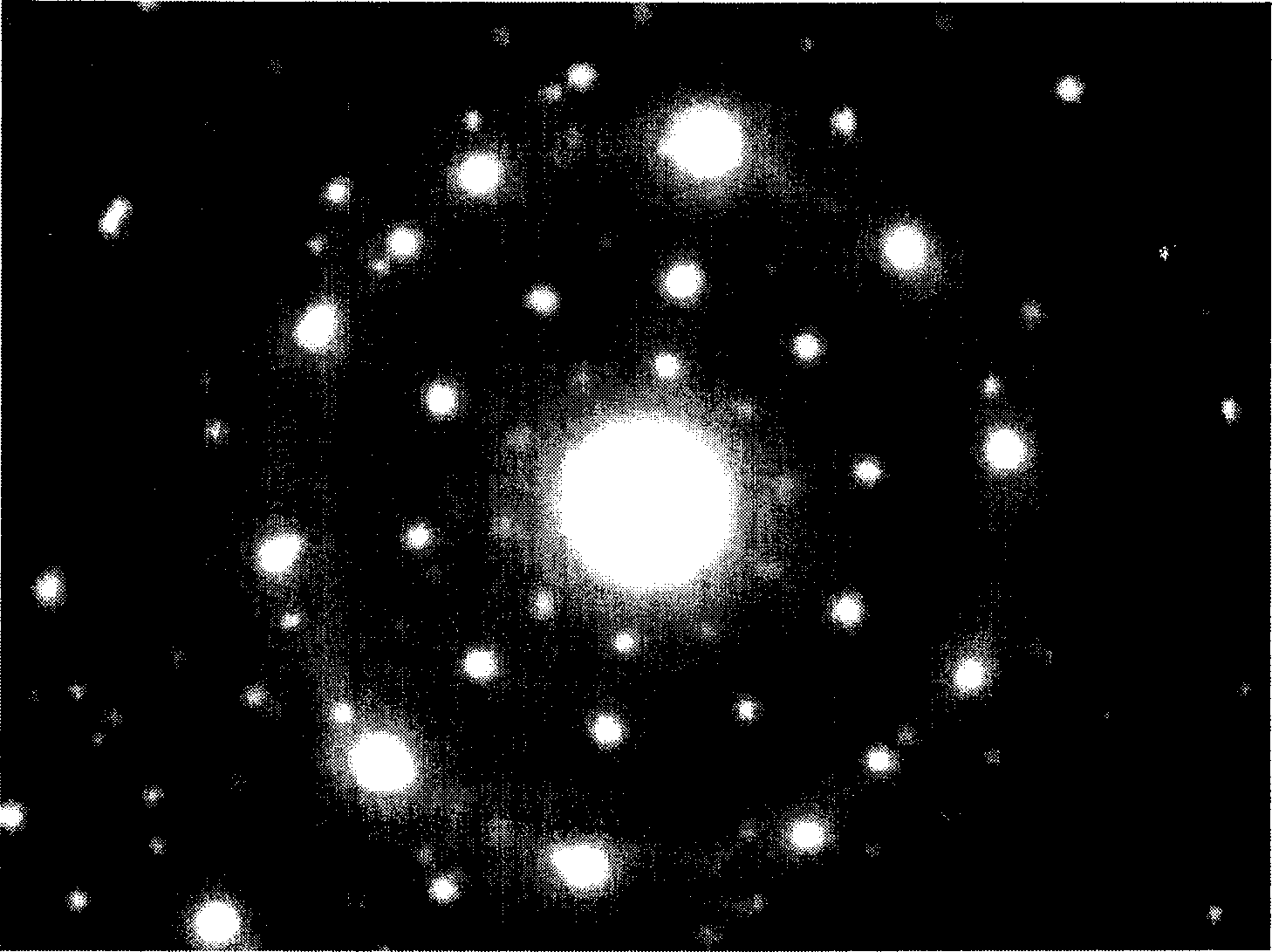

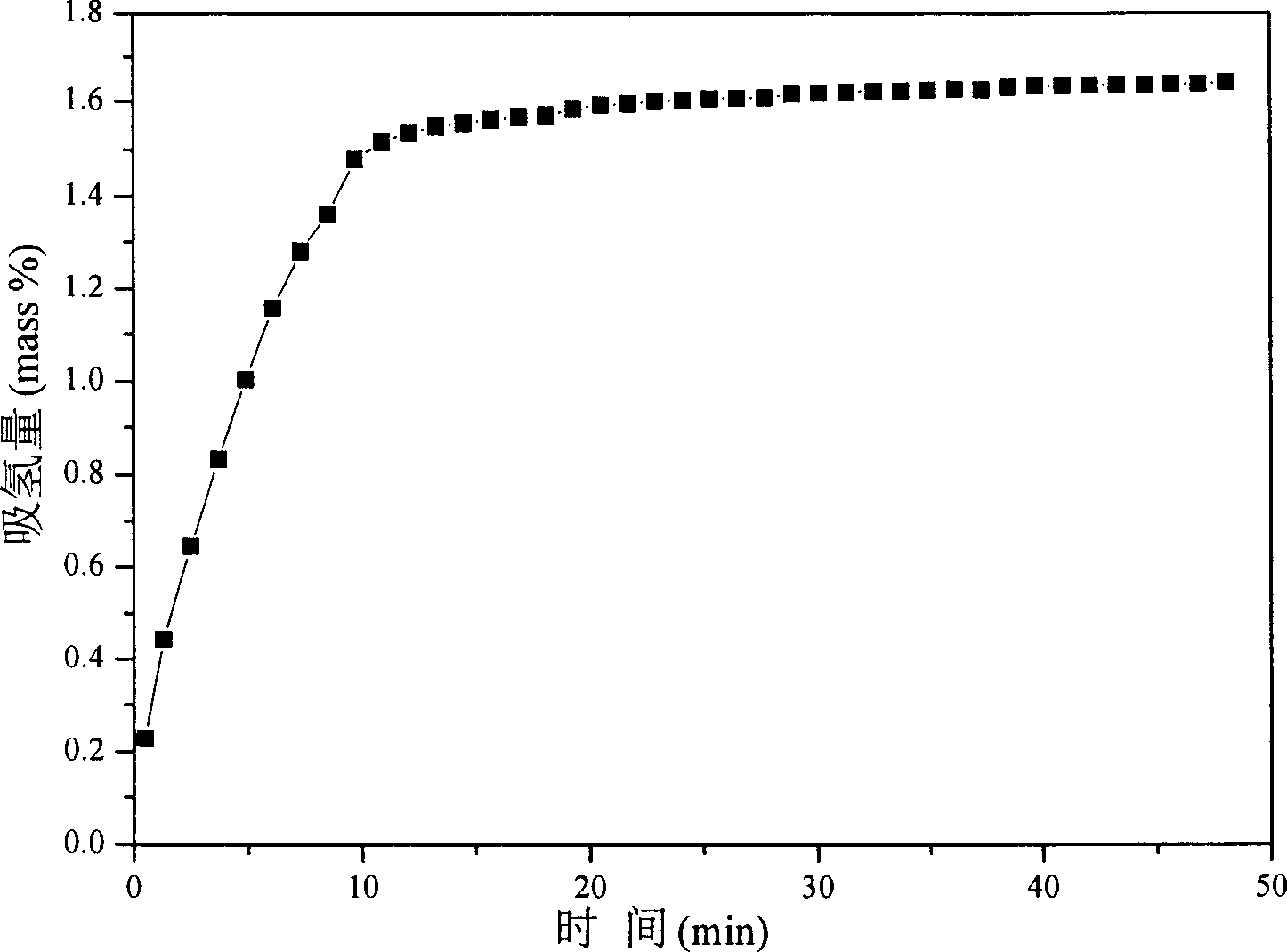

[0014] By composition Ti 45 Zr 35 Ni 17 Cu 3 , choose 100 mesh chemically pure Ti, Zr, Ni, Cu powder, put it into the ball mill tank of high energy ball mill, the ball to material ratio is 20:1, under the protection of argon, ball mill for 200 hours, the alloy powder after ball milling is sealed into quartz tube, in 1 x 10 -3 Heat treatment is carried out under Pa, the temperature is 580 ℃, the time is 0.5 hour, the obtained alloy powder is analyzed by XRD and electron diffraction, the results are as follows figure 1 and figure 2 , indicating that the alloy is a single icosahedral quasicrystal structure. Then measure the physical hydrogen storage capacity and hydrogen absorption performance. At 250°C, the mass percentage of hydrogen absorption in 20 minutes reaches 1.6mass%, and the hydrogen absorption kinetics curve is as follows: image 3 ; At the same time, its electrochemical absorption-desorption performance was measured in the negatively limited MH-Ni experimental...

Embodiment 2

[0016] The composition is Ti 65 Ni 30 Zr 10 Cu 5 , ball milled for 150 hours, and heat treated at 580°C for 1 hour. All the other are with embodiment 1. The XRD results of the alloy are as follows Figure 5 , indicating a single icosahedral quasicrystal structure. At 250°C, the mass percentage of hydrogen absorbed in 20 minutes reaches 1.8mass%. At 50°C, one cycle reaches the maximum discharge capacity of 512mAh / g, and the charging experiment is carried out at 50°C±1°C, and the QH is 93%.

Embodiment 3

[0018] The composition is Ti 50 Ni 30 Zr 10 Cu 10 , ball milled for 100 hours, and heat treated at 530°C for 3 hours. All the other are with embodiment 1. The alloy is a single regular icosahedral quasicrystal structure. At 250°C, the mass percentage of hydrogen absorbed in 20 minutes reaches 1.4mass%. At 30°C, the maximum discharge capacity is 376mAh / g in one cycle. The charging experiment was carried out at 30°C±1°C, and the QH was 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com