Suspension rack for disk drive

A disk drive and suspension technology, applied in the configuration/installation of the recording head, supporting the head, etc., can solve the problem of vibration of the beam part

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

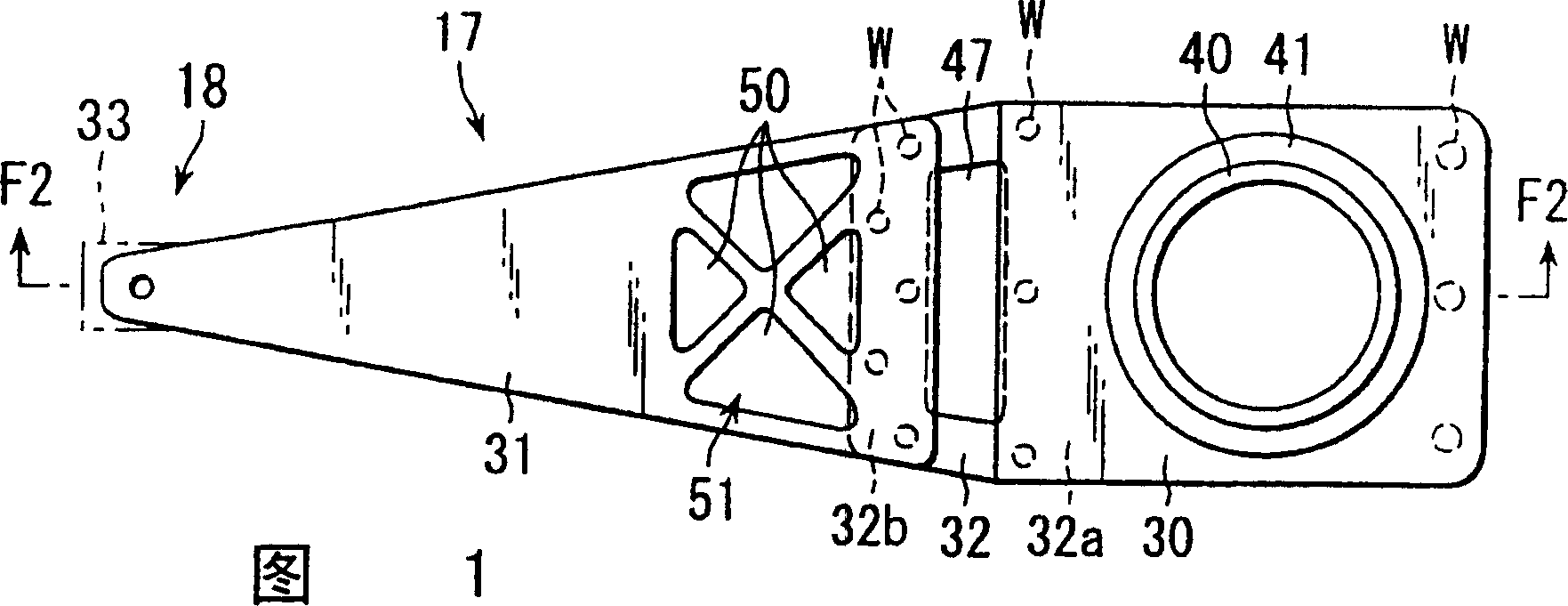

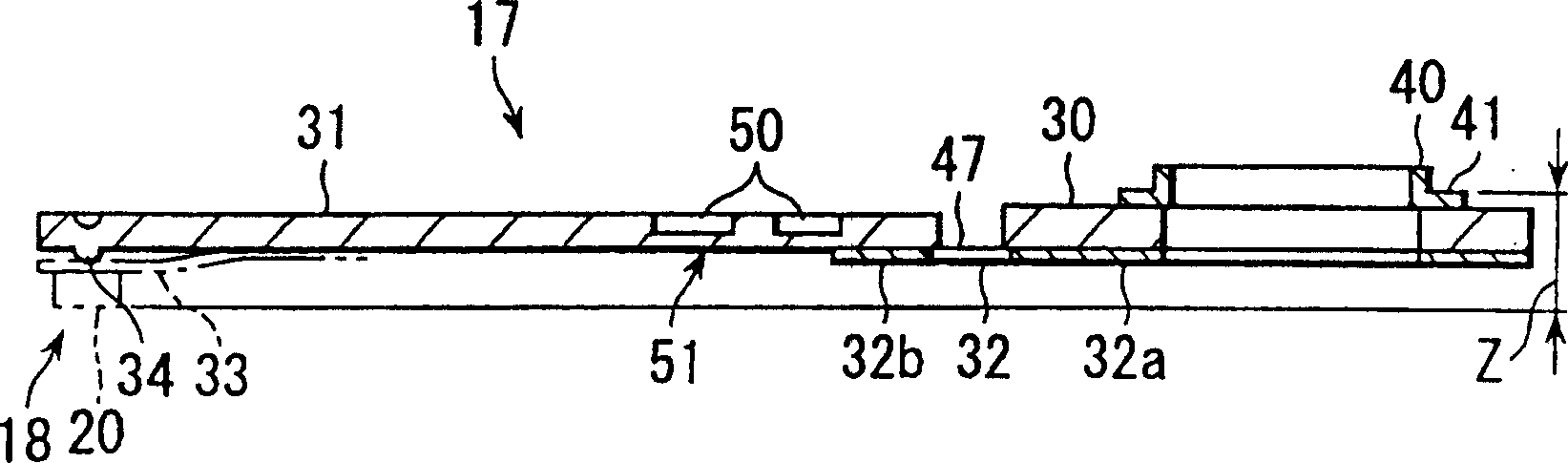

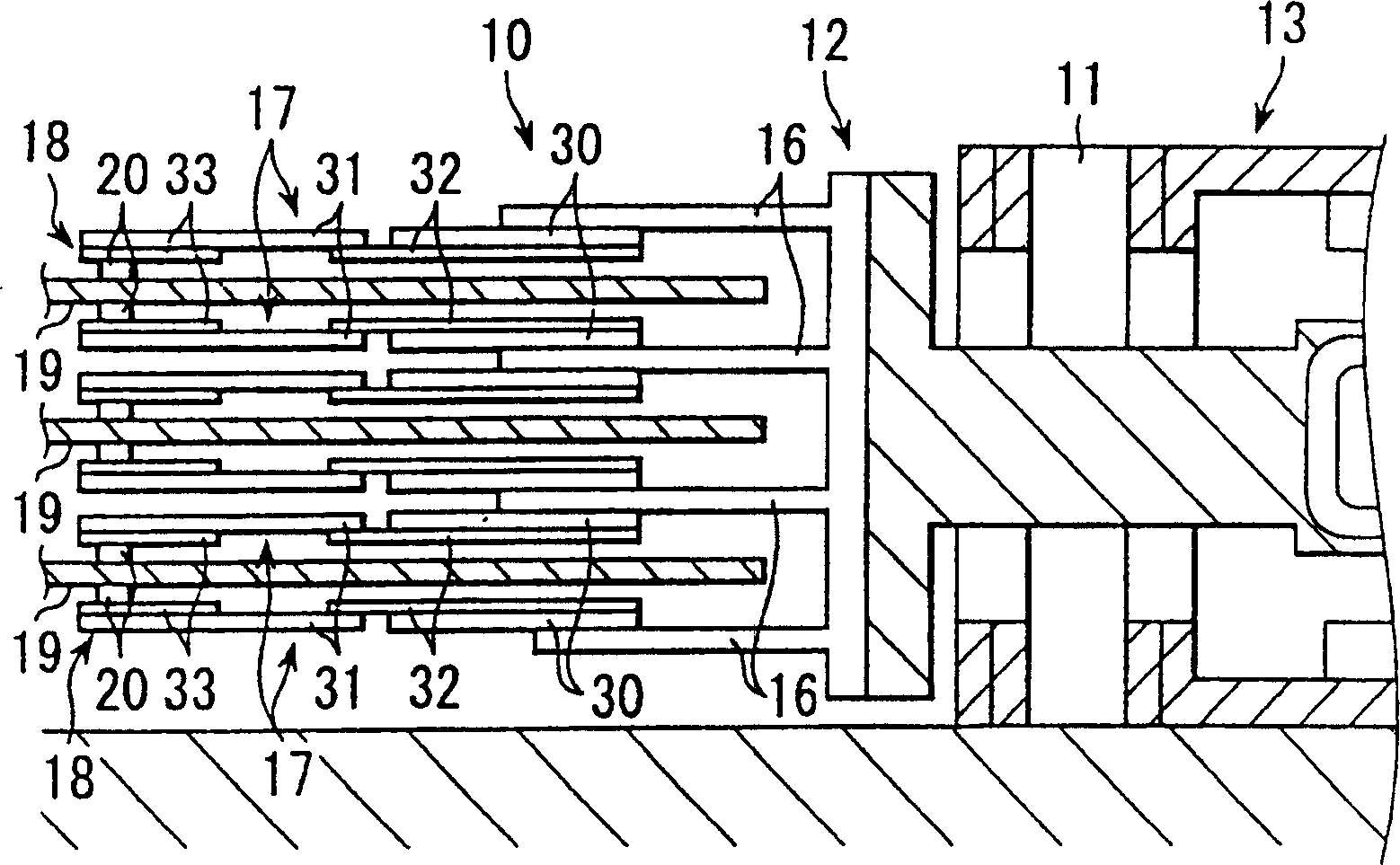

[0026] A first embodiment of the present invention will now be described with reference to FIGS. 1 to 3 . image 3 The hard disk drive (HDD) shown includes a bracket 12 which is rotatable about an axis 11 . Carriage 12 is rotated about shaft 11 by a position controlled motor 13, such as a voice coil motor. Mounted on the bracket 12 are arms (actuating arms) 16, suspensions 17 each mounted on each end portion of the arm 16, a head 18 mounted on each end portion of the suspension 17, and the like. When the carriage 12 is driven by the motor 13, the head 18 moves to the desired track of the magnetic disk 19.

[0027] The head 18 includes a slider 20 positioned to face the recording surface of the magnetic disk 19, and a sensor (not shown) fixed to the slider 20. When the disk 19 rotates at high speed, air enters the space between the disk 19 and the slider 20 and rises slightly away from the disk 19, thereby forming an air cushion between the disk 19 and the slider 20.

[0028...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com