Fluorophor detecting method and fluorophor detecting apparatus

A detection method and detection device technology, applied in measuring devices, photometry, fluorescence/phosphorescence, etc., can solve the problems of uneven illumination, no interference fringes, interference fringes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

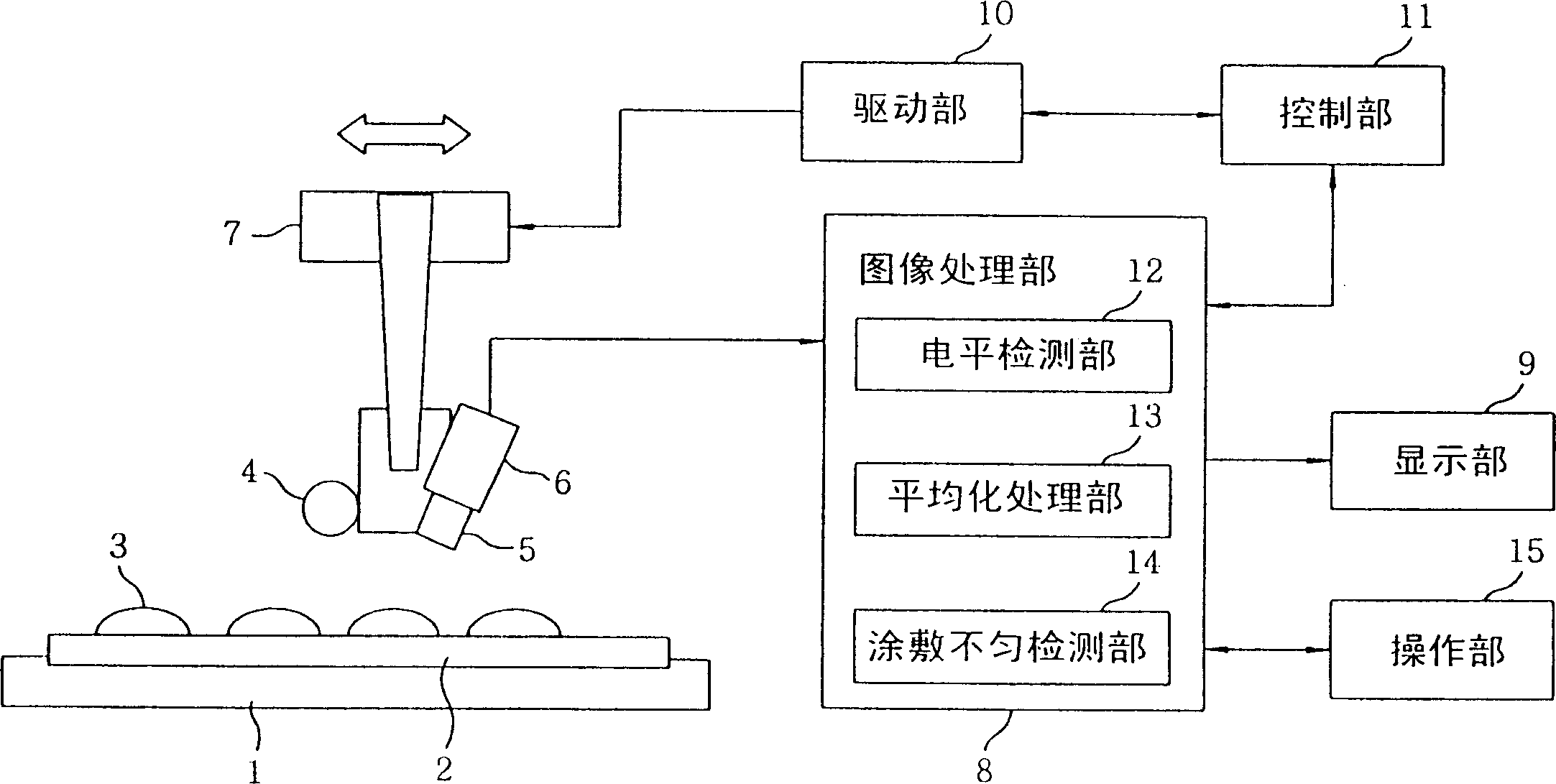

[0035] figure 1 One embodiment of the phosphor detection device of the present invention is shown. figure 1 Among them, 1 denotes a table for placing glass substrates such as plasma displays, 2 denotes glass substrates such as plasma displays, 3 denotes R, G, and B phosphor strips, 4 denotes a light source for ultraviolet illumination that makes phosphor strips 3 emit light, and 5 denotes sequential mounting. An optical system with lenses and R, G, and B color filters, 6 represents an imaging unit such as a line sensor camera for imaging, and 7 indicates a moving mechanism for scanning the upper part of the glass substrate 2 along the substrate 2 with the light source 4 and the imaging unit 6 8 represents an image processing part for detecting uneven coating, 9 represents a display part such as a color monitor for displaying detection results, and may also be composed of a printing part such as a printer, 10 represents a driving part for driving the moving mechanism part 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com