Single tooth, biteeth shaped large angle flexible laminated coupler

A large-angle, coupling technology, applied in elastic couplings, couplings, mechanical equipment, etc., can solve problems such as fretting wear, angle compensation cannot be large, and limit development and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

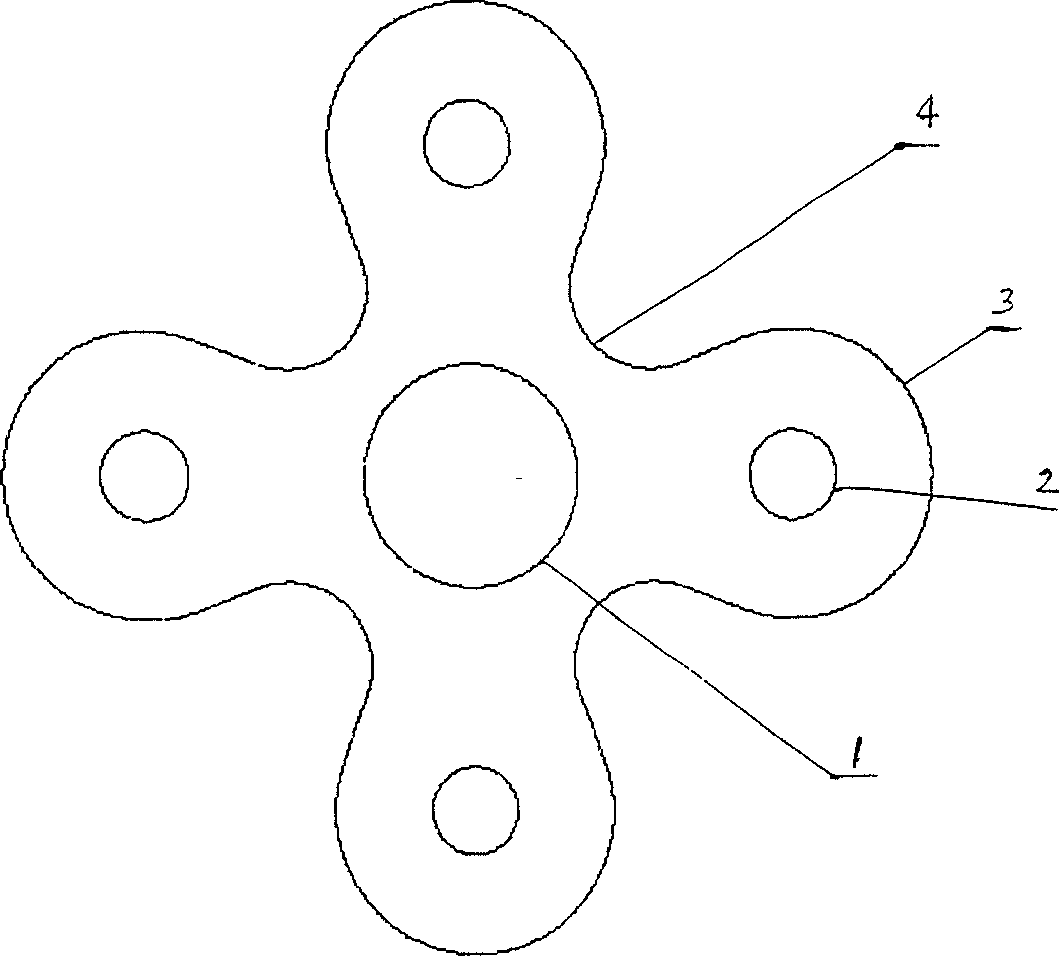

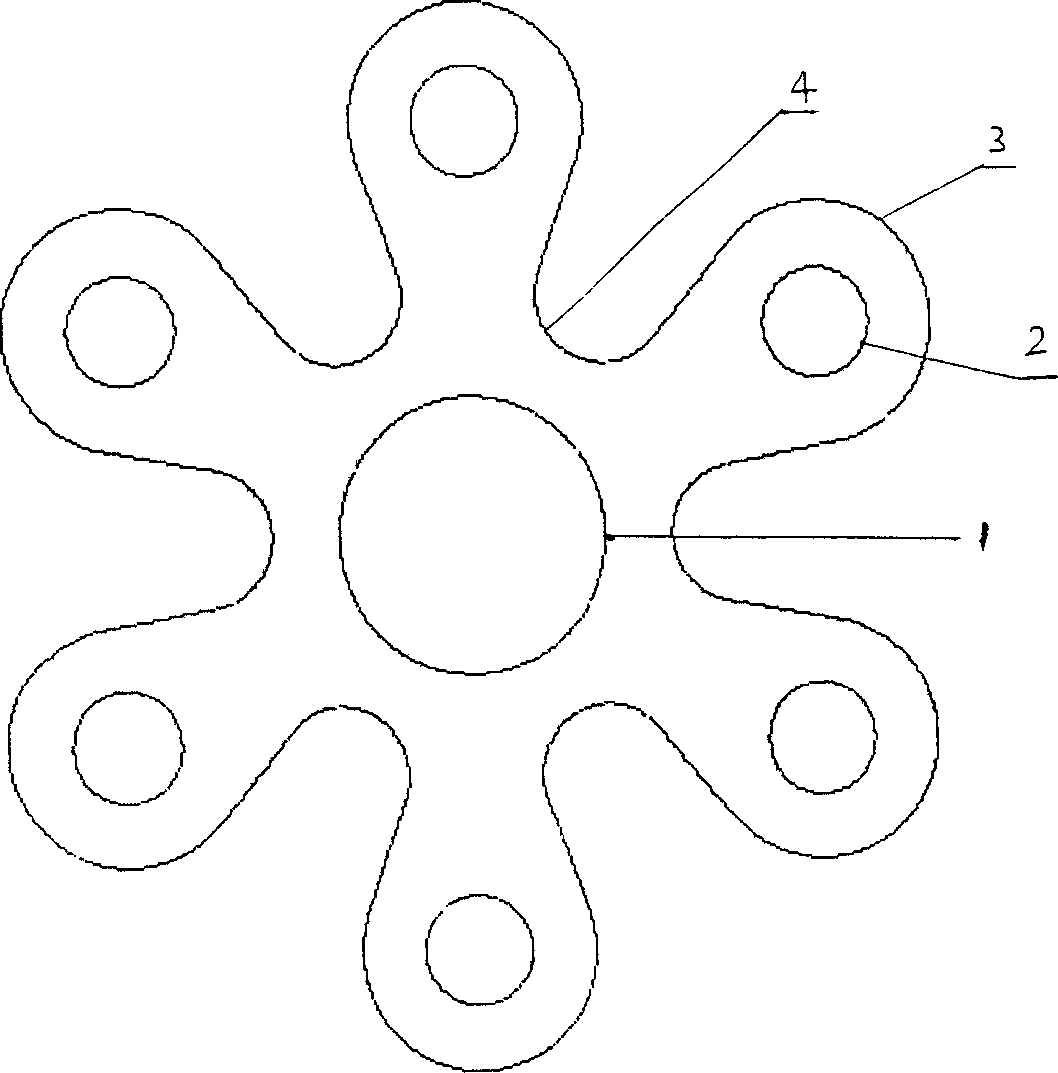

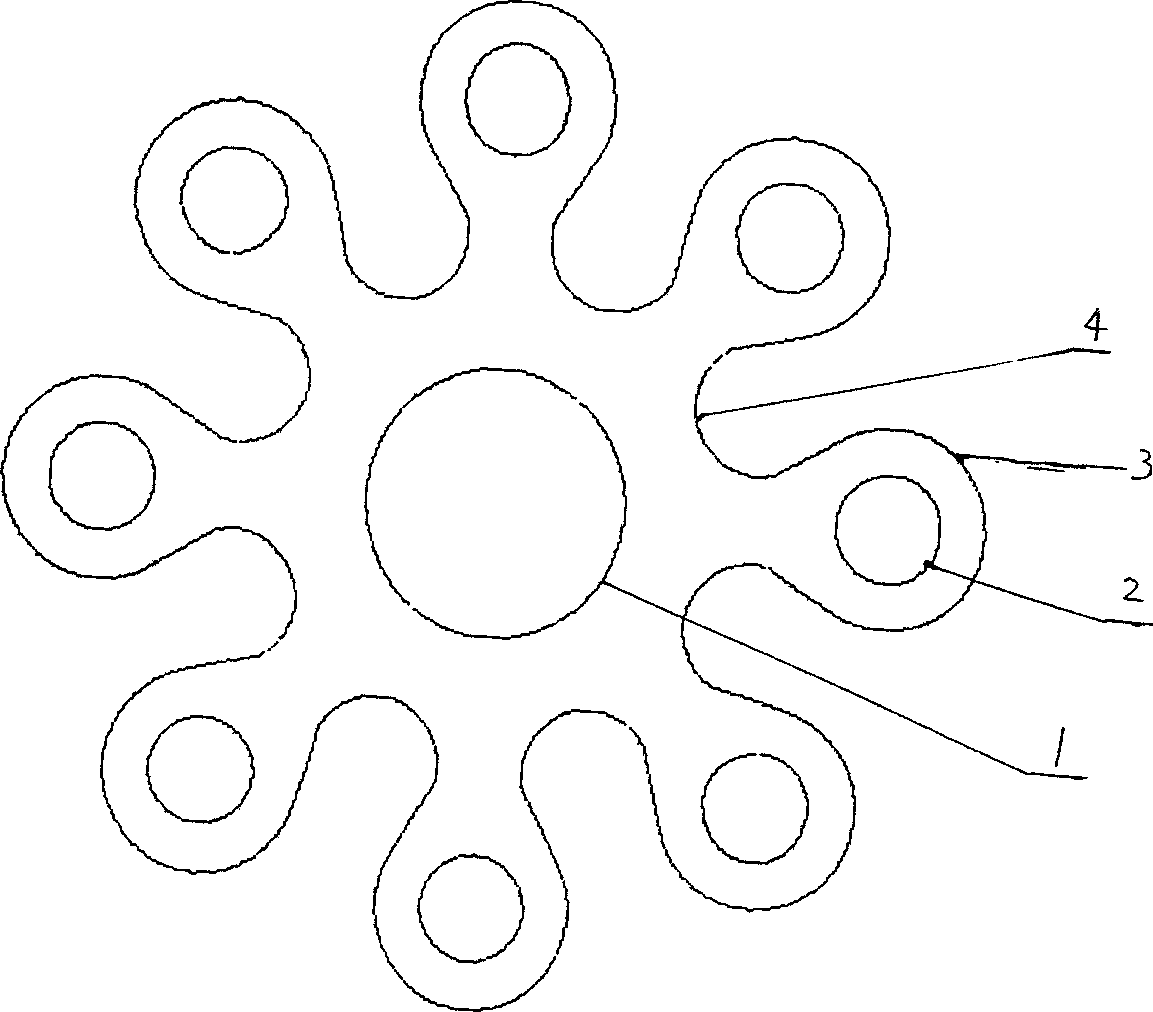

[0023] Figure 1 is a schematic diagram of the planar structure of a single-tooth-shaped large-angle flexible lamination coupling with a single-tooth concave arc. exist There is a bolt hole circle 2 with the same radius on each of the 2n angle bisectors, and there are 2n lamination outer circle arcs 3 with the same radius as the bolt hole circles with the same center as the 2n bolt hole circles respectively. Each of the 2n angle bisectors between two adjacent bolt hole circles 2 has a single-tooth concave arc 4, and the outer circular arc 3 of the lamination is tangent to the single-tooth concave arc by an outer common tangent line. Thus, the distance from the center of the lamination shaft to the center of the single-tooth concave arc is smaller than the distance from the center of the lamination shaft to the center of the bolt hole plus the radius of the outer arc of the lamination. n in 2n is equal to 2, 3, 4, 5, 6 respectively. Therefore, there are 4-hole, 6-hole, 8-hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com