Hydraulic valve controller for heavy construction installation

A technology for control devices and construction equipment, applied in the direction of fluid pressure actuation devices, mechanical equipment, transportation and packaging, etc., can solve the problems of reducing work efficiency, complex design, distracting drivers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

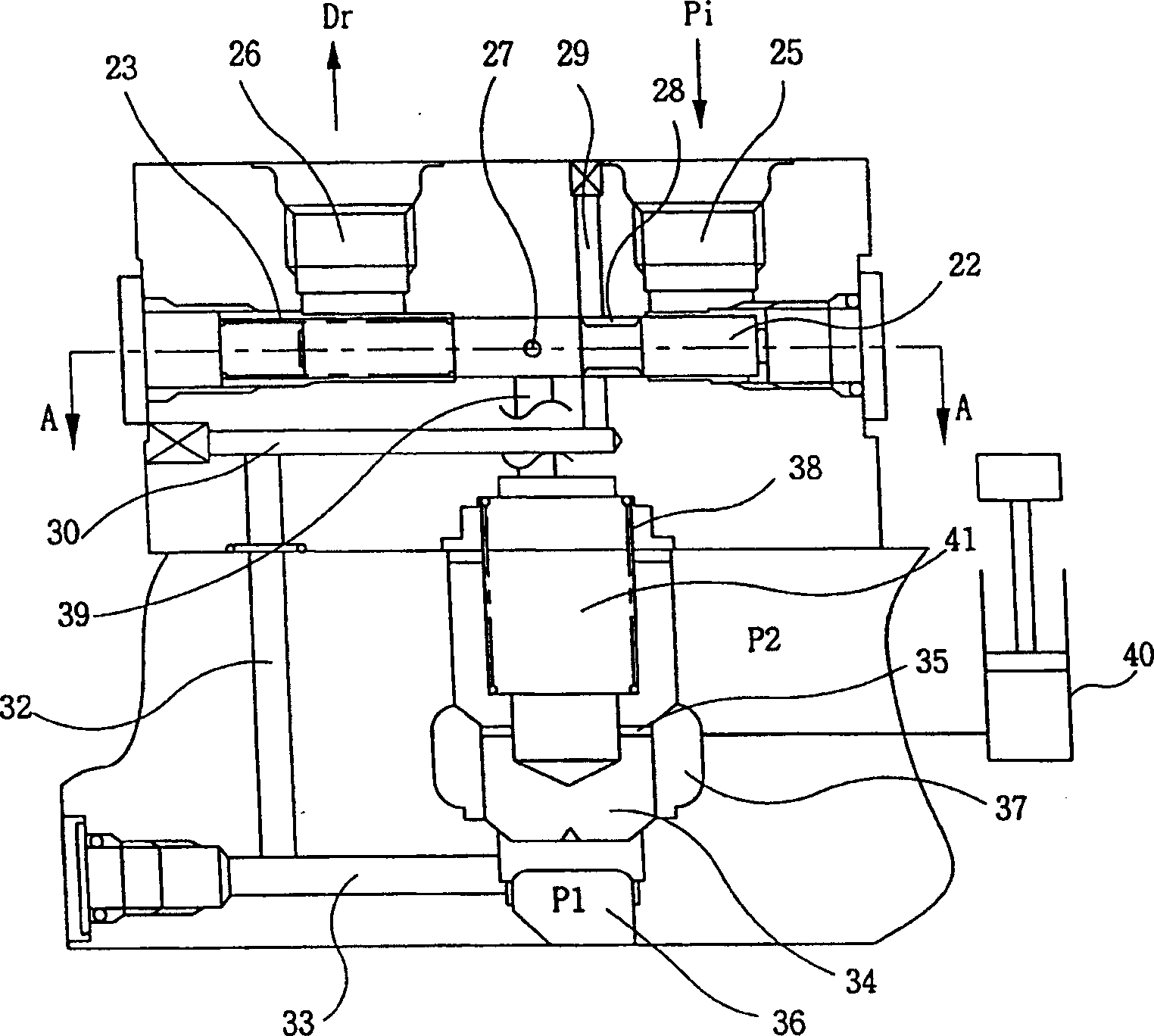

[0025] A hydraulic valve control device for heavy construction equipment according to a preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0026] figure 2 Shown is a cross-sectional view of a hydraulic valve control device for heavy construction equipment according to an embodiment of the present invention, image 3 shown along figure 2 In the sectional view of line A-A, FIG. 4 is a schematic diagram of the hydraulic return pipeline of the hydraulic valve control device according to the embodiment of the present invention.

[0027] Such as figure 2 As shown in FIG. 4, the hydraulic valve control device for heavy construction equipment includes a hydraulic pump not shown, an actuator 40 connected to the hydraulic pump and driven when supplying hydraulic fluid, and an actuator 40 installed on the hydraulic pump and the actuator The main spool shaft barrel 42 on the channel between the actuators 40 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com