Purification method of kieselguhr filler

A diatomaceous earth and drying technology, applied in chemical instruments and methods, silicon compounds, silicon oxide, etc., can solve the problems that have not been reported, cannot effectively remove impurities, and have poor effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

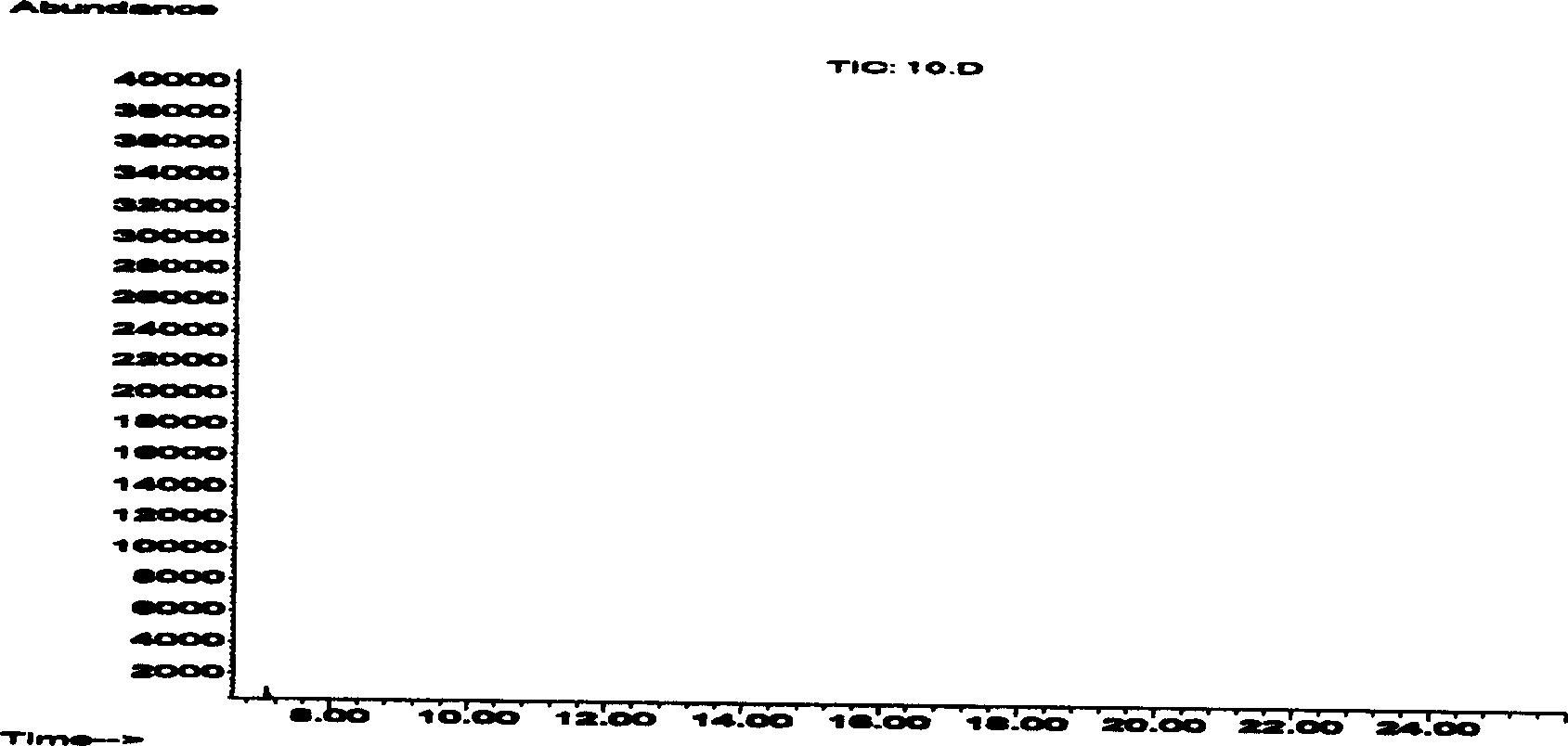

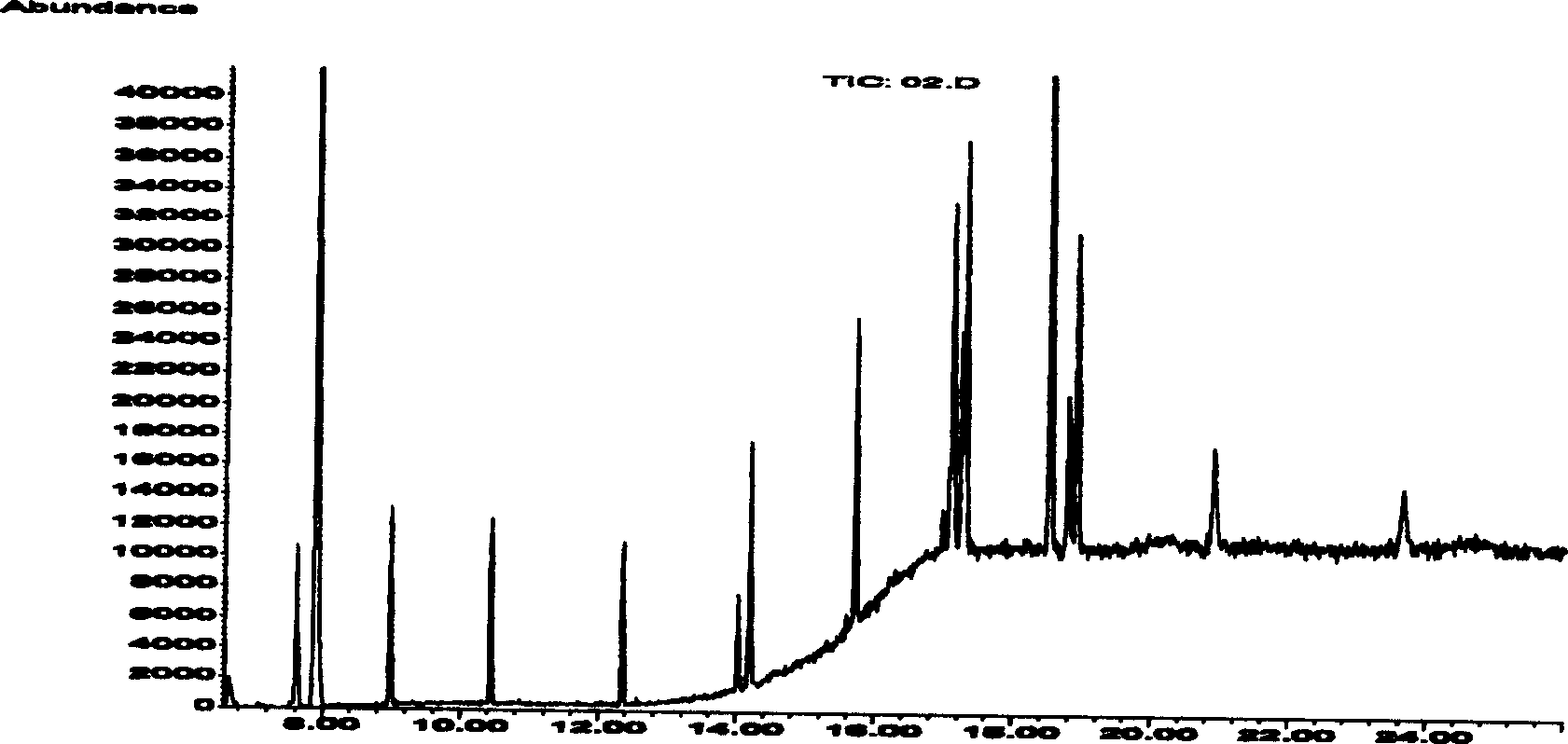

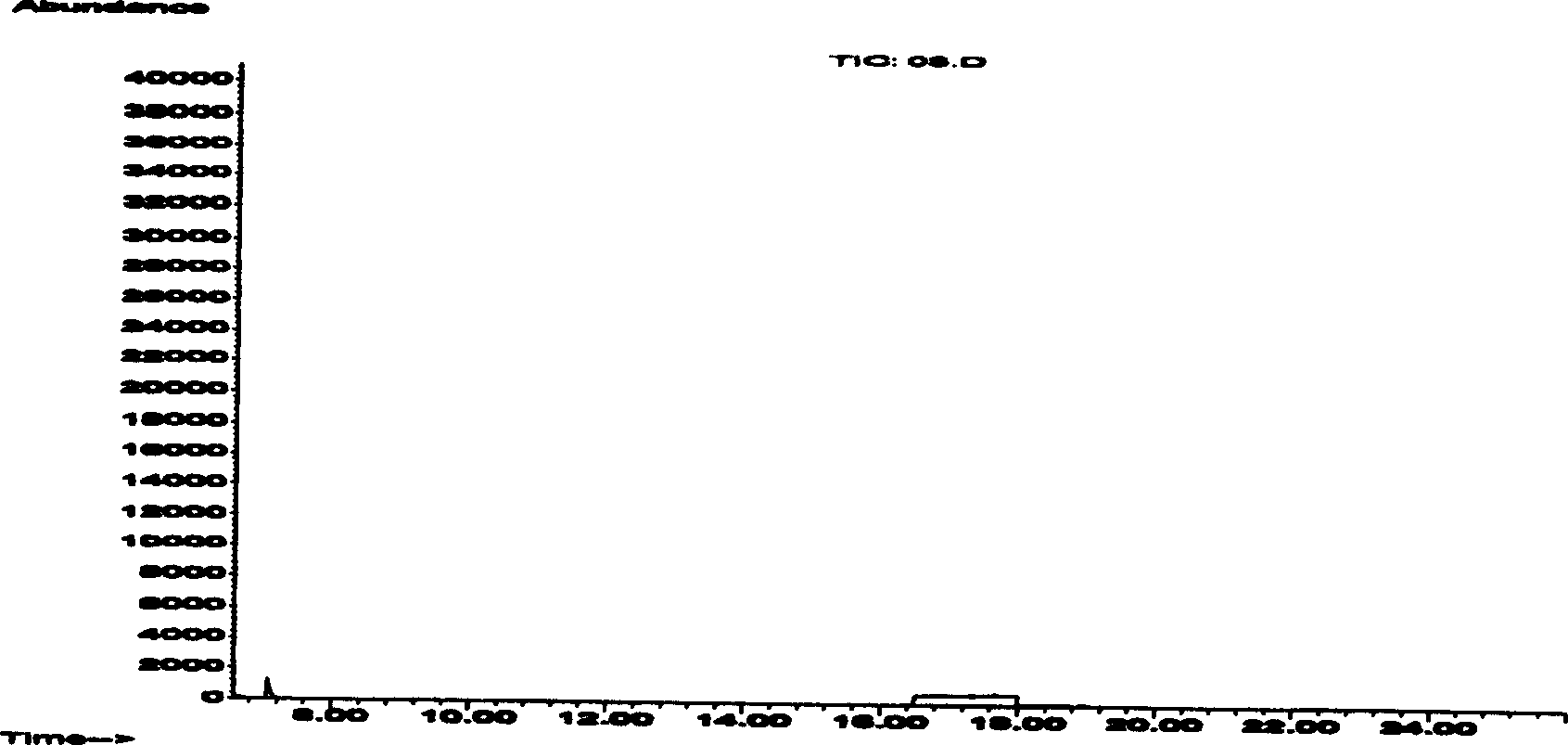

Image

Examples

Embodiment Construction

[0025] The method of the present invention is specifically described below in conjunction with embodiment:

[0026] (1), the diatomite filler is washed with sulfuric acid or hydrochloric acid, and washed with water after washing;

[0027] (2), after drying above-mentioned diatomite filler, wash with ethanol or acetone;

[0028] (3), volatilize and dry the diatomite filler after washing with ethanol or acetone;

[0029] (4) Burn the dried diatomite filler, the burning temperature is 750°C, and the burning time is 24 hours continuously.

[0030] (5) After burning, use a water bath to cool, and the cooling water temperature is below 10°C;

[0031] (6), carry out vacuum packing after removing powder with 100 mesh filter sieves.

[0032] The burning temperature is 550°C, 600°C, 700°C, 750°C, 800°C, and 850°C, and the burning time is 12 hours, 24 hours, 36 hours, and 48 hours. The test results prove that when the temperature is 550°C, 600°C, 700°C, and the time is shorter than 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com