Cutter squirt device for green papermaking

A water-needling and green technology, applied in the field of papermaking, can solve the problems of reduced reliability and complex device structure, and achieve the effects of convenient maintenance, simple equipment installation and strong reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

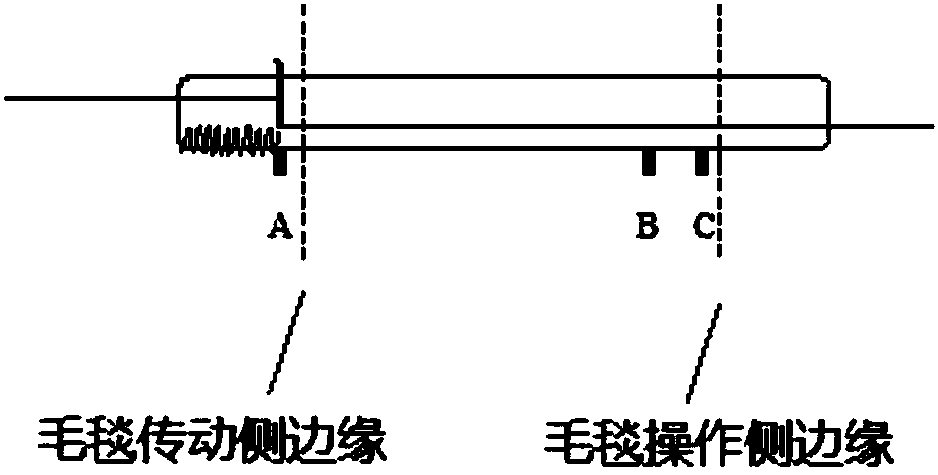

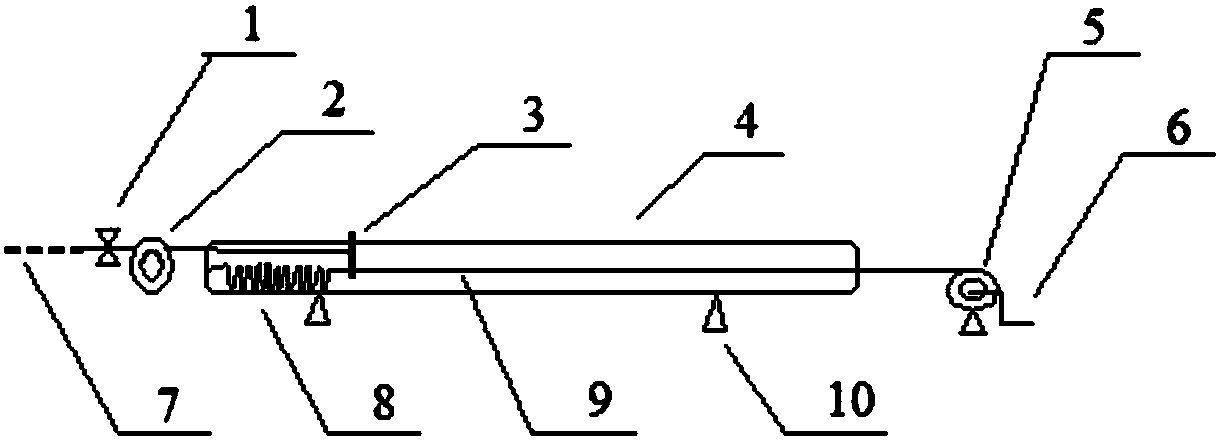

[0031] A paper-leading water needle device for green papermaking, its structure is as follows figure 1 As shown, it includes a casing 4 slotted in the axial direction, a water needle nozzle 3 which is arranged in the casing 4 and moves axially, a steel wire rope 9 and a spring rope 8 connected to both sides of the water needle nozzle 3, and the spring rope 8 The outer end is fixed on the inner wall of the shell 4, and the outer end of the wire rope 9 is wound on the wire rope storage tray 5, which is also connected with a crank handle 6 to control the retraction of the wire rope 9.

[0032] The water needle nozzle 3 is made of stainless steel or ruby, and the diameter of the water outlet is not greater than 1mm. The water needle nozzle 3 communicates with the water inlet pipe 7, and the water inlet pipe 7 is also provided with a valve 1. Water is sprayed out through the water needle nozzle 3 to form a water needle, and the water pressure is adjusted through the valve 1 accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com