Manufacturing method for investment casting ceramic mould shell containing filter of golf head

A golf club head and investment precision casting technology, which is applied to golf balls, golf clubs, casting molding equipment, etc., can solve problems such as easy splashing, reduced production efficiency, and low yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

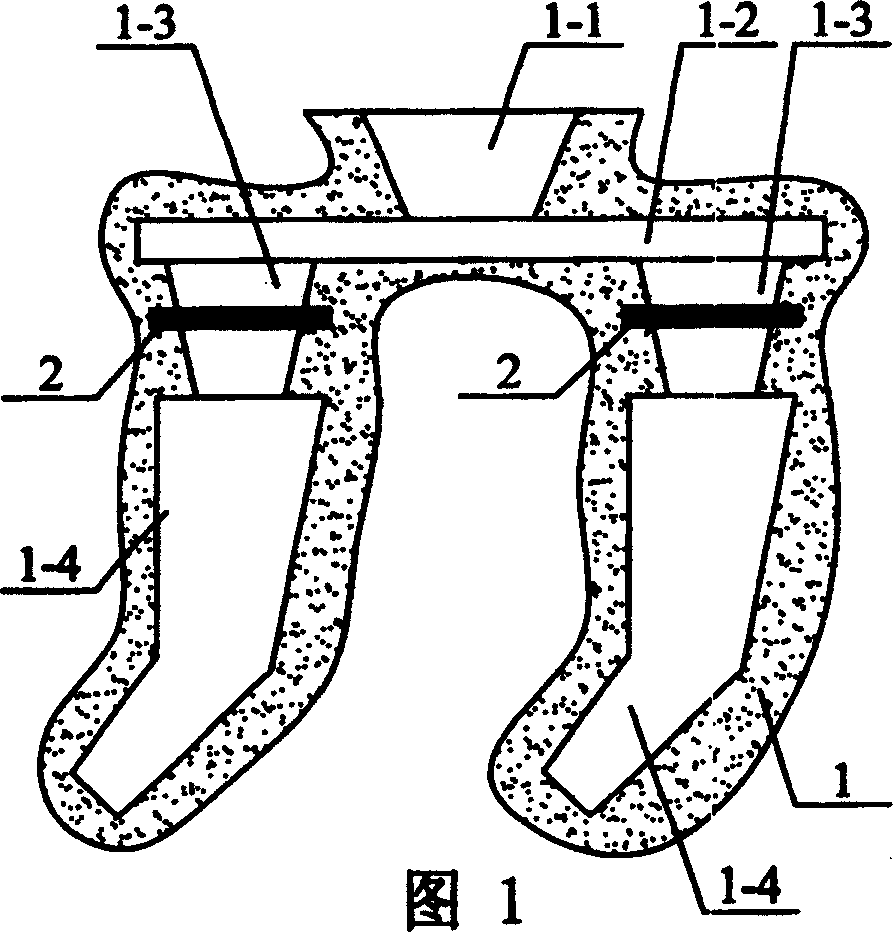

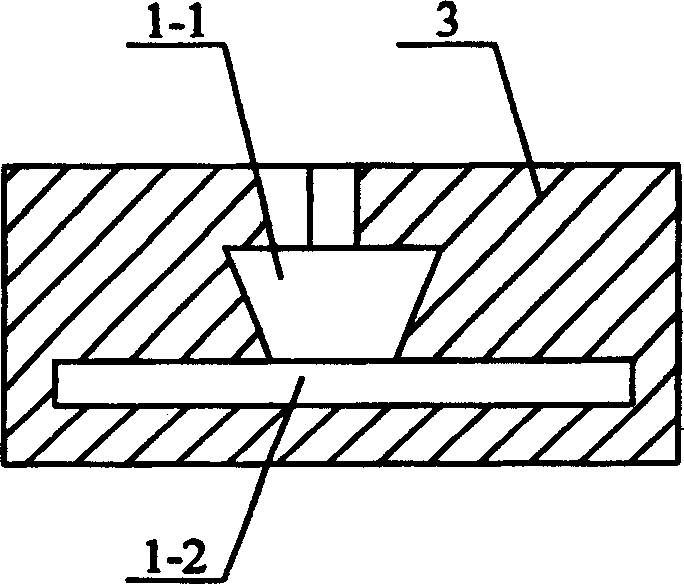

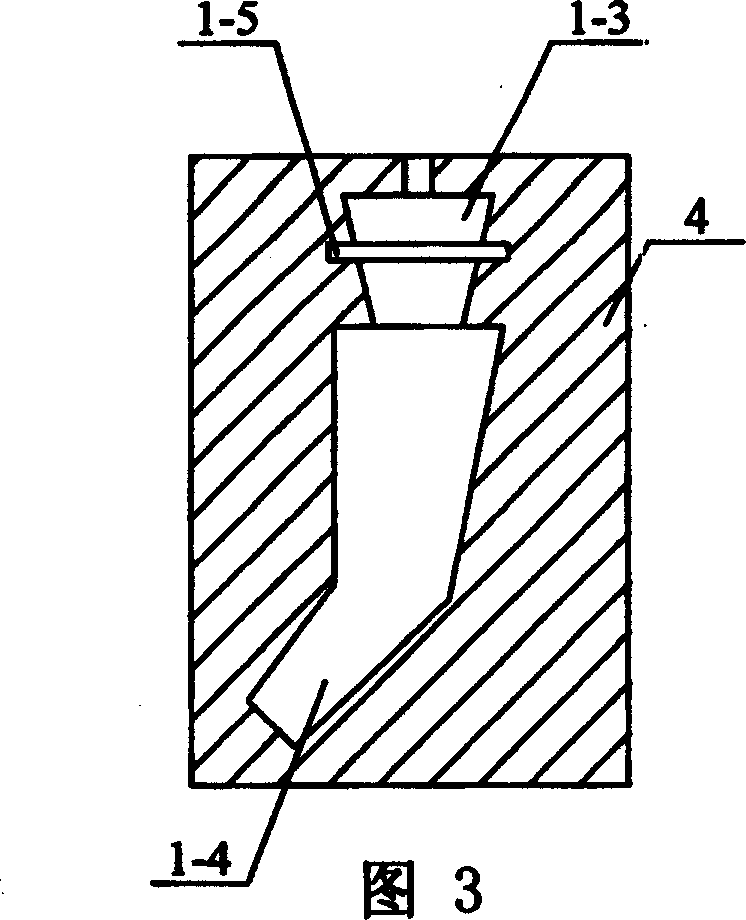

[0005] Combined with Figure 1, figure 2 ,image 3, Figure 4 , Figure 5 ,Image 6, Figure 7 , Figure 8 Describe this embodiment, this embodiment is made up of ceramic shell 1, a plurality of filters 2; 1-4 composition; the cup bottom of sprue cup 1-1 is connected to the upper feed port of die head 1-2, and multiple lower end discharge ports of die head 1-2 are respectively connected to multiple ingates 1-3 The upper end feed port of multiple ingates 1-3 is respectively connected to the upper end feed ports of multiple casting cavities 1-4; the outer edge of the filter 2 is embedded in the inner sprue 1-3 On the inner wall of the inner middle part, the ingate 1-3 is divided into upper and lower cavities by the filter 2 . What the filter 2 selects for use is a ceramic fiber filter screen or a ceramic foam filter sheet. The preparation method of the present invention is a, making the die head mold 3 of band sprue cup 1-1 and die head 1-2, as figure 2 ; B, make the wax pat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com