Rotor for hammer- or chopper mill

A pulverizer and rotor technology, applied in the field of rotors, can solve problems such as bulky structure and achieve the effect of enhancing the overall stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Two embodiments of the rotor structure according to the present invention are described in detail below.

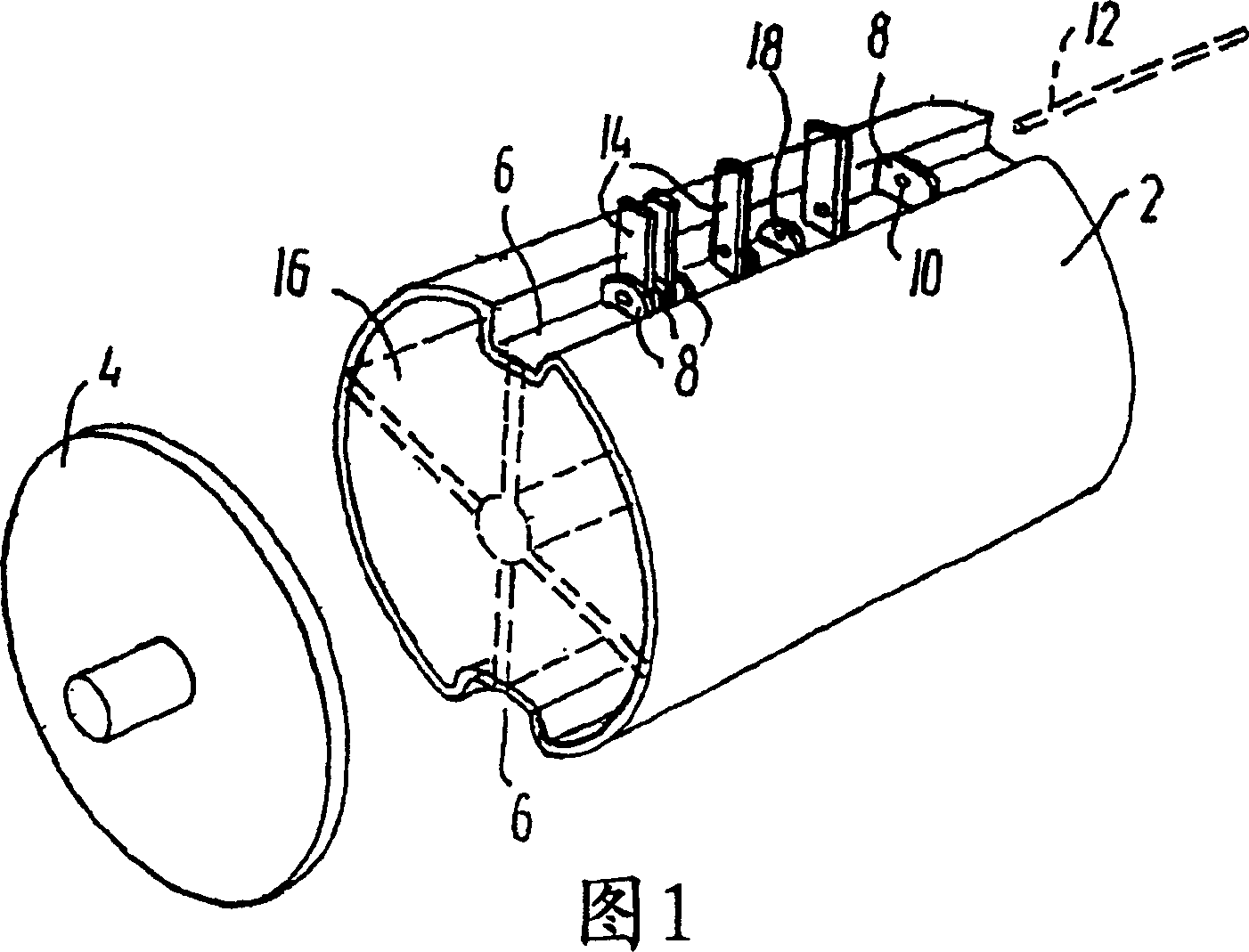

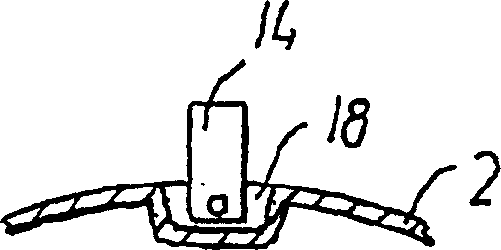

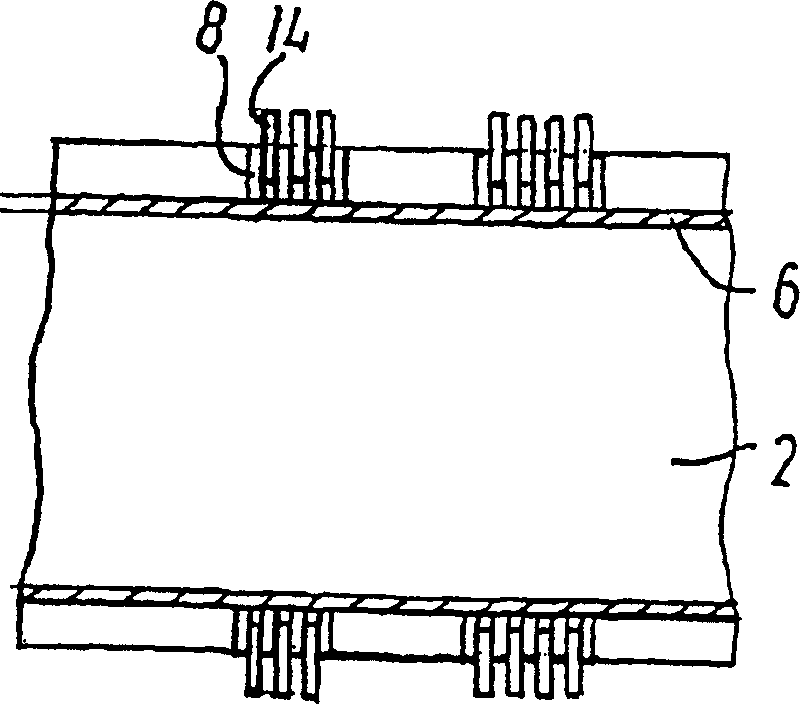

[0017] Referring to Figure 1, there is shown a sleeve 2, preferably made of sheet steel, provided with corresponding end portions 4. The profile of the sleeve 2 is provided with a pair of longitudinally extending grooves 6, in which a plurality of laterally positioned fastening plates 8 are fixed, and the fastening plates are provided with small holes 10 for accommodating a longitudinally extending Strut 12. In the openings between the plates 8 is provided a pivotally fixed series of radially outwardly extending chopping blades 14 pivotable about base holes for receiving said struts 12 . The sleeve 2 is stabilized by means of radially extending wings 16 located between the inner wall of the sleeve 2 and an extension 19 ′ of a central drive shaft 19 .

[0018] see image 3 , the series of chopping blades 14 in the two opposite grooves 6 shown in Fig. out) the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com