Holographic coupling element and its manufacturing method, and holographic laser unit and optical pickup device

A coupling element and optical pickup technology, applied in the direction of beam guiding device, optics, optical components, etc., can solve the problems of light loss, weakening of laser beam, and lower reliability, so as to reduce labor time, reduce labor time, reduce light loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0093] Referring now to the accompanying drawings, preferred embodiments of the present invention will be described in detail.

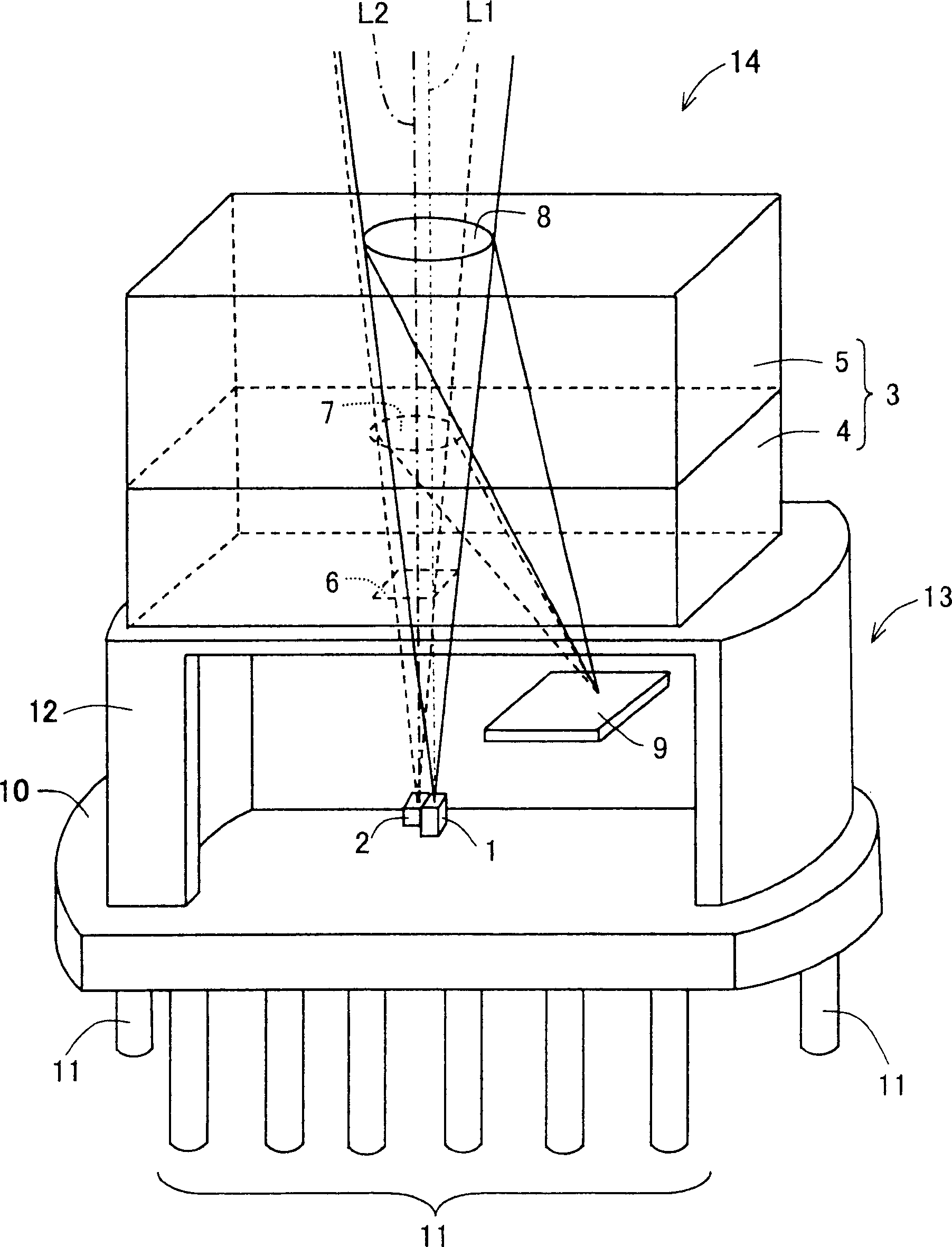

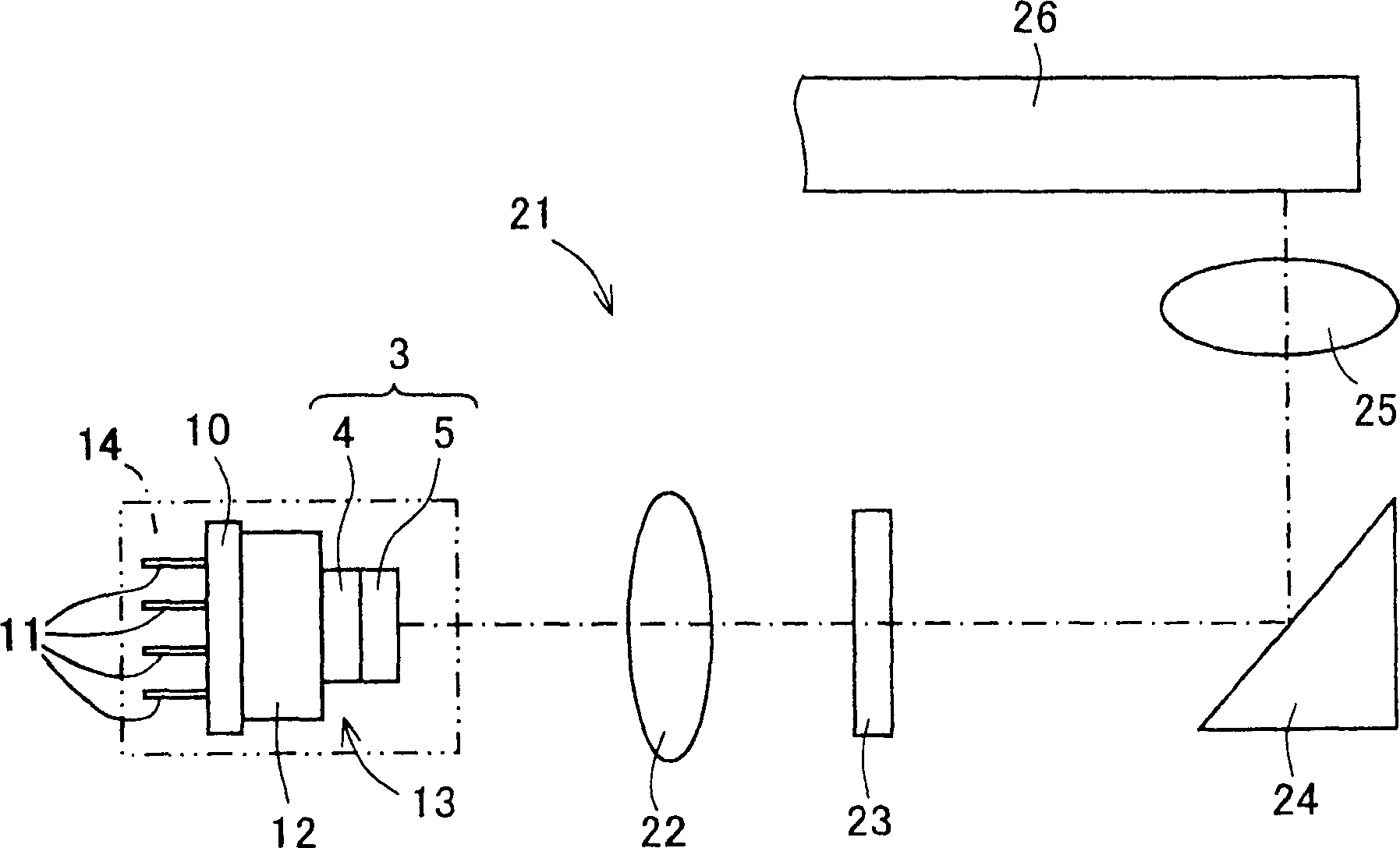

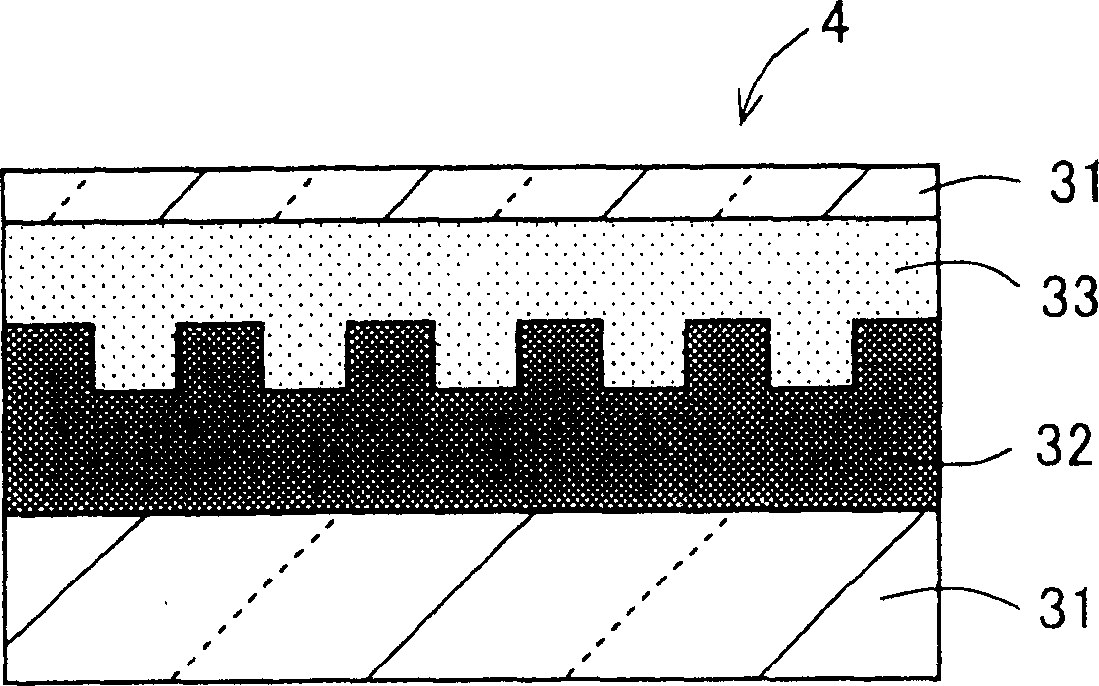

[0094] figure 1 A simplified perspective view showing the structure of a holographic laser unit 14 including a holographic coupling element 3 of an embodiment of the present invention. exist figure 1 , the cover 12 described later is partially cut away for display. The holographic laser unit 14 includes the holographic coupling element 3 and the semiconductor laser device 13 . The semiconductor laser device 13 includes a first semiconductor laser device 1 , a second semiconductor laser device 2 , a light receiving device 9 , a stem 10 , an electrode 11 , and a cover 12 . The holographic coupling element 3 includes a first polarization hologram substrate 4 as a first substrate and a second polarization hologram substrate 5 as a second substrate. The first polarization hologram substrate 4 includes a three-beam diffraction grating 6 and a first pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com