Method of exhausting and in-situ hydrothermally synthesizing type-A molecular sieve film

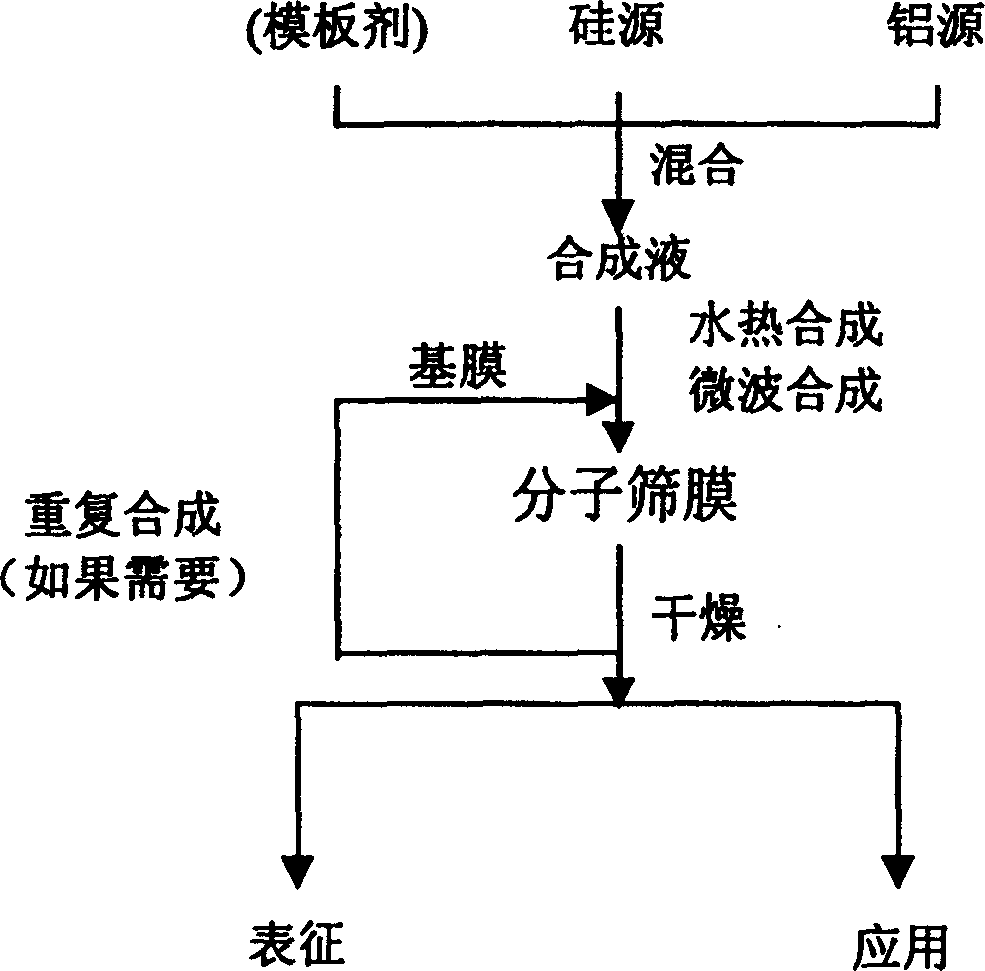

An in-situ hydrothermal and molecular sieve technology, which is applied in chemical instruments and methods, A-type crystalline aluminosilicate zeolite, membrane technology, etc. Different levels of difficulty, etc., to achieve the effect of increasing the speed, reducing the synthesis time, and improving the synthesis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1 Basement Membrane Preparation

[0038] α-Al used in the experiment 2 o 3The base membrane is prepared by casting method, the outer diameter of the membrane tube is 10mm, the inner diameter is 7mm, the length is 260mm, the pore radius is 0.5-1.0μm, and the porosity is about 50%. The base film was smoothed with fine sandpaper, ultrasonically washed in distilled water, and treated at high temperature for later use.

[0039] Step 2 Reaction solution preparation

[0040] Weigh a certain amount of NaOH and dissolve it in distilled water, add aluminum foil after clarification, and stir to form an aluminum solution; measure a certain amount of silica sol and add it to pre-heated distilled water, stir well; slowly add the pre-heated aluminum solution to the silica sol , continue stirring for a few minutes. The composition (molar ratio) of each component in the final solution is 50Na 2 O:Al 2 o 3 : 5SiO 2 : 1000H 2 O.

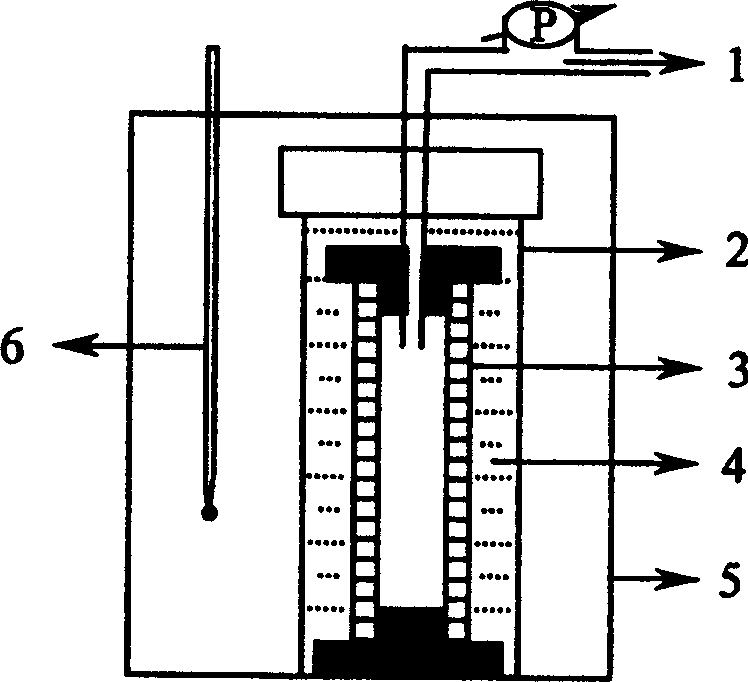

[0041] Step 3: Evacuate in-situ hydrotherma...

Embodiment 2

[0044] Step 1 Basement Membrane Preparation

[0045] Same as example 1.

[0046] Step 2 Reaction solution preparation

[0047] Repeat Step 2 of Example 1.

[0048] Step 3: Evacuate in-situ hydrothermal synthesis of type A molecular sieve membrane

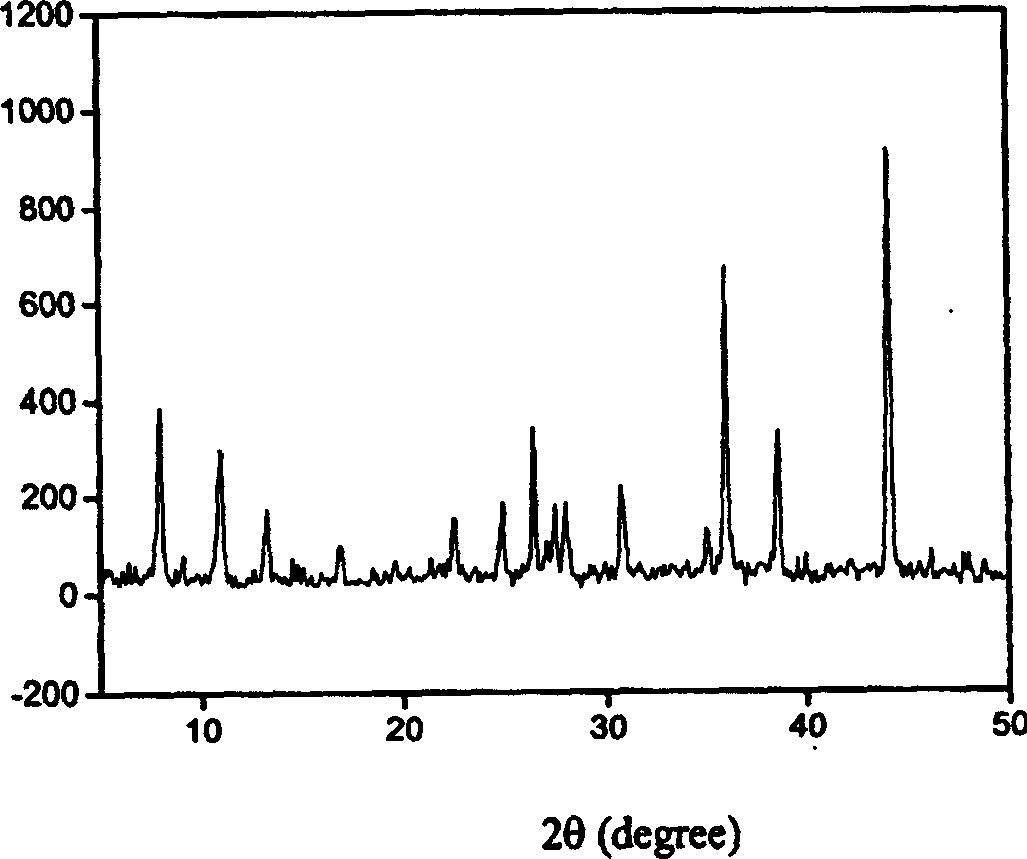

[0049] After the basement membrane is fixed, place it vertically in the evacuated in-situ hydrothermal synthesis reactor, adjust the pressure difference between the inside and outside of the basement membrane tube to 0.0150MPa, and evacuate for 200Min; pour the reaction solution, and perform the in-situ hydrothermal synthesis at 363K for 2 to 8 hours Take it out, cool it to room temperature, wash it with distilled water until neutral, dry it and use it for characterization and pervaporation experiments.

Embodiment 3

[0051] Step 1 Basement Membrane Preparation

[0052] Same as example 1.

[0053] Step 2 Reaction solution preparation

[0054] Repeat Step 2 of Example 1

[0055] Step 3: Evacuate in-situ hydrothermal synthesis of type A molecular sieve membrane

[0056] After the basement membrane is fixed, place it vertically in the evacuated in-situ hydrothermal synthesis reactor, adjust the pressure difference between the inside and outside of the basement membrane tube to 0.0200MPa, and compress for 500Min; pour the reaction solution, and then evacuate the in-situ hydrothermal synthesis at 363K for 2 to 8 hours Take it out, cool it to room temperature, wash it with distilled water until neutral, dry it and use it for characterization and pervaporation experiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com