Preparation method of p-aminophenol

A technology of p-aminophenol and sodium p-nitrophenolate, which is applied in the field of preparation of p-aminophenol, can solve the problems of "three wastes" pollution from iron powder reduction, difficulty in catalyst recovery and application, troublesome post-treatment separation, etc., and achieve the improvement of internal competitiveness and External image, good economic and social benefits, and the effect of low investment in equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

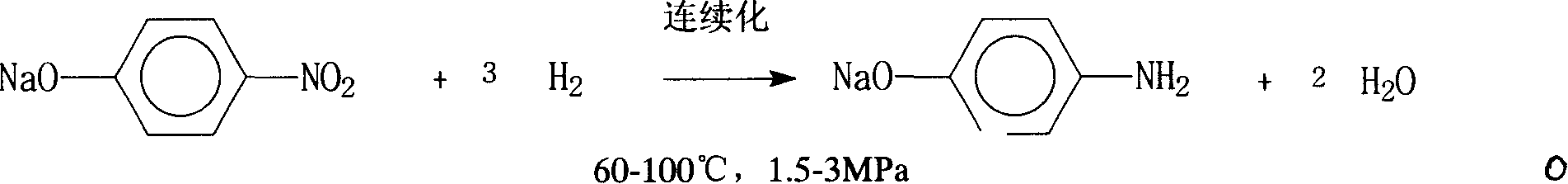

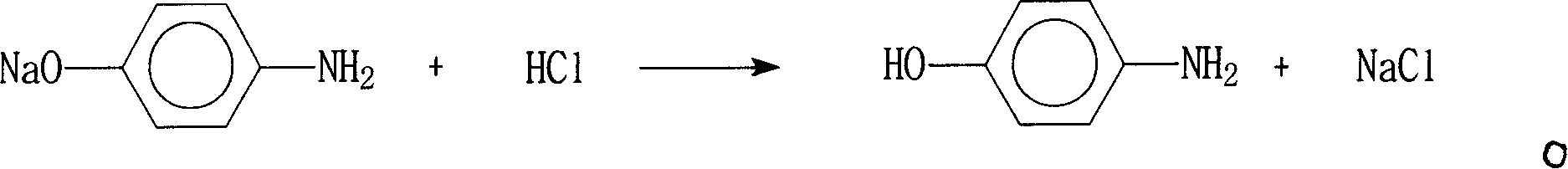

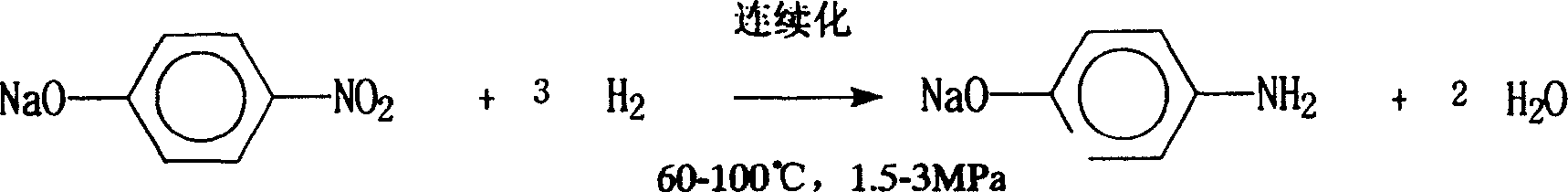

[0013] The present invention prepares p-aminophenol by adopting sodium p-nitrophenolate aqueous solution in hydrogenation tower for continuous hydrogenation reduction reaction, acidification reaction and collecting p-aminophenol from the mixture after acidification reaction, and hydrogenating to Φ108*3000 through a pressure regulator Continuously and stably feed 2.2Mpa of hydrogen into the tower, fill the tower with 12kg of 20% Ni-C catalyst, select the hydrogenation reduction pressure at 1.5-3.0Mpa, preferably at 2Mpa, and at the same time slightly open the tail gas valve to make the tail gas slightly bulge Bubble. Turn on the heating voltage of the tower and the feeding pipeline to increase the temperature in the tower to 60-100°C, preferably 90°C. Such a temperature can make the raw materials not easy to precipitate, the reaction liquid is homogeneous, and the raw materials can be completely reacted. To improve the conversion rate, the temperature of the feed pipe is contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com