Odd number agar oligosaccharide monomer and its preparation method

A technology of agar oligosaccharides and monomers, applied in the direction of oligosaccharides, etc., can solve the problems of low solubility, large molecular weight, high viscosity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

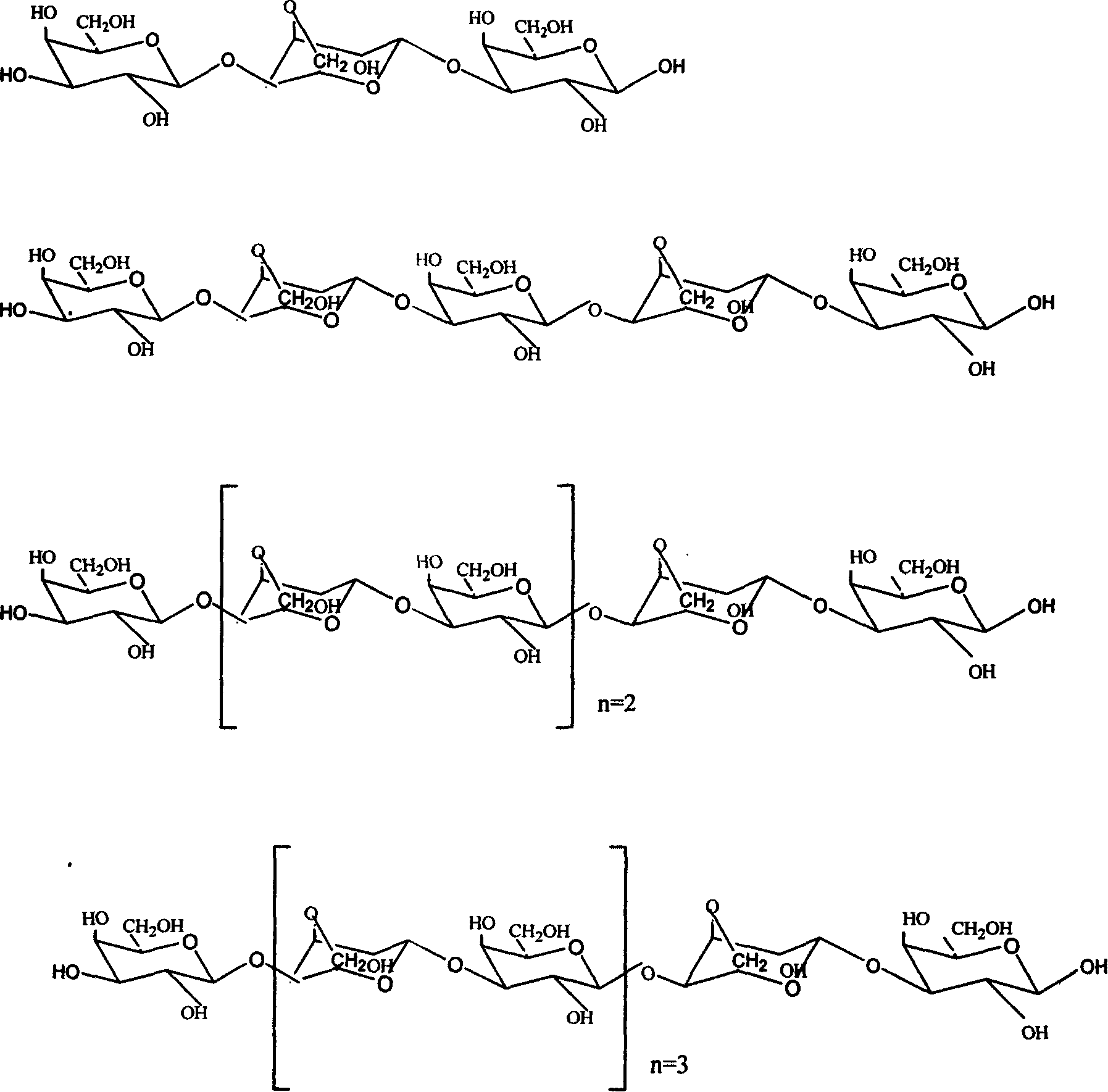

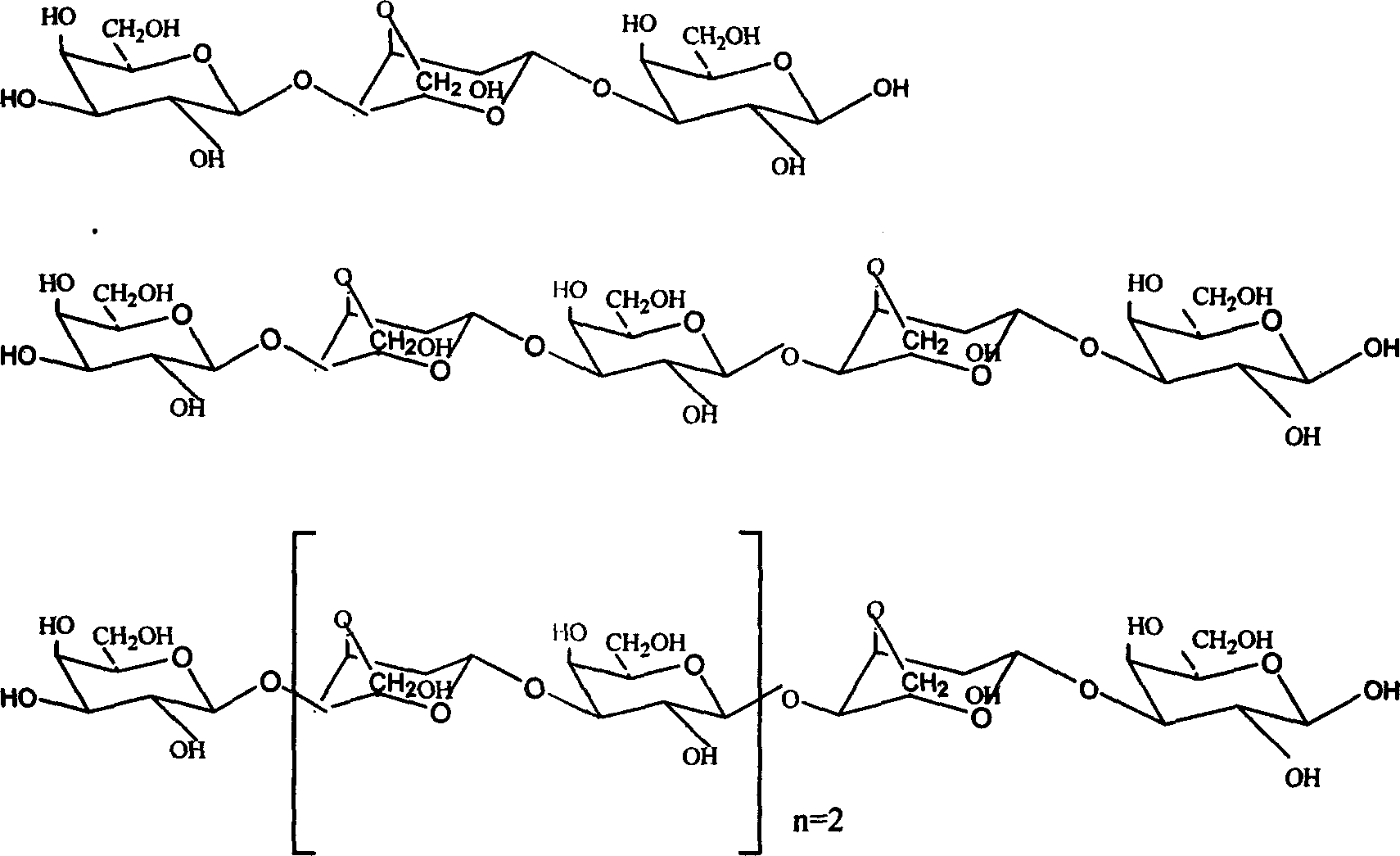

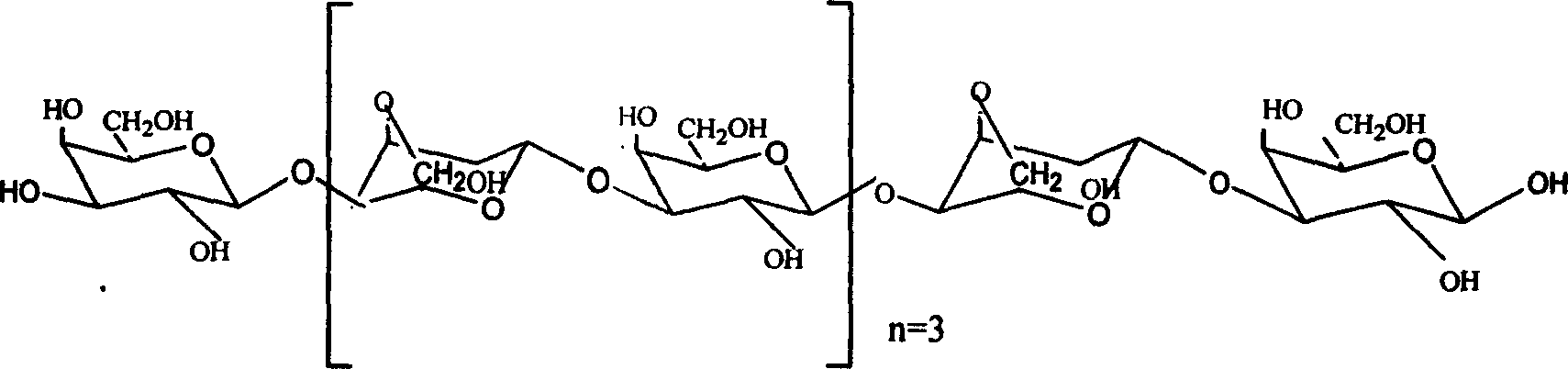

Image

Examples

Embodiment 1

[0010] Take 10g of agarose, add 1000ml of distilled water and heat it to dissolve, add 5ml of 2mol / L sulfuric acid aqueous solution, stir and hydrolyze in a water bath at 80°C for 240min, after the reaction is completed, cool the reactant to room temperature with a cold water bath, add barium carbonate to neutralize To neutral, filter with suction, concentrate the filtrate to 100ml under reduced pressure at 40°C, add 4 times the amount of ethanol to cause precipitation, centrifuge, concentrate the supernatant under reduced pressure at 40°C, and freeze-dry to obtain an oligosaccharide mixture. Take 2g of the oligosaccharide mixture, add 1ml of water to dissolve it, inject it into a Superdex30 chromatographic column, and elute with distilled water at room temperature, combine the eluents from each sugar peak, concentrate under reduced pressure, and freeze-dry to obtain agarose and agarose pentaose , Qiongqiose, Qiongjiutang.

Embodiment 2

[0012] Take 100g of agarose, add 5000ml of distilled water and heat to dissolve, add 15ml of 3mol / L hydrochloric acid solution, stir and hydrolyze in a water bath at 70°C for 7h, after the reaction is completed, cool the reactant to room temperature in a cold water bath, and add barium carbonate to neutralize To neutral, filter with suction, concentrate the filtrate to 200ml under reduced pressure at 40°C, add 4 times the amount of methanol to cause precipitation, centrifuge, concentrate the supernatant under reduced pressure at 40°C, and freeze-dry to obtain the oligosaccharide mixture. Take 10g of the oligosaccharide mixture, add 1ml of water to dissolve it, inject it into a Bio-Gel-P6 chromatographic column, and elute with distilled water at room temperature, combine the eluents of each sugar peak, concentrate under reduced pressure, and freeze-dry to obtain agarose , Qiongpentose, Qiongqiose, Qiongjiutang.

[0013] The agar or agarose described in the present invention is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com