Method for making ceramic art utensils

A technology for craft ceramics and a production method, which is applied in crafts and decorative arts for producing decorative surface effects, can solve the problems of monotonous color, dislocation of patterns, time-consuming and other problems, and achieve vivid colors, exquisite patterns, and cost reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

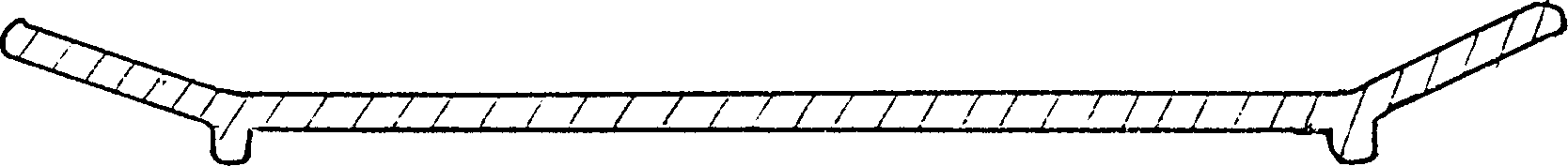

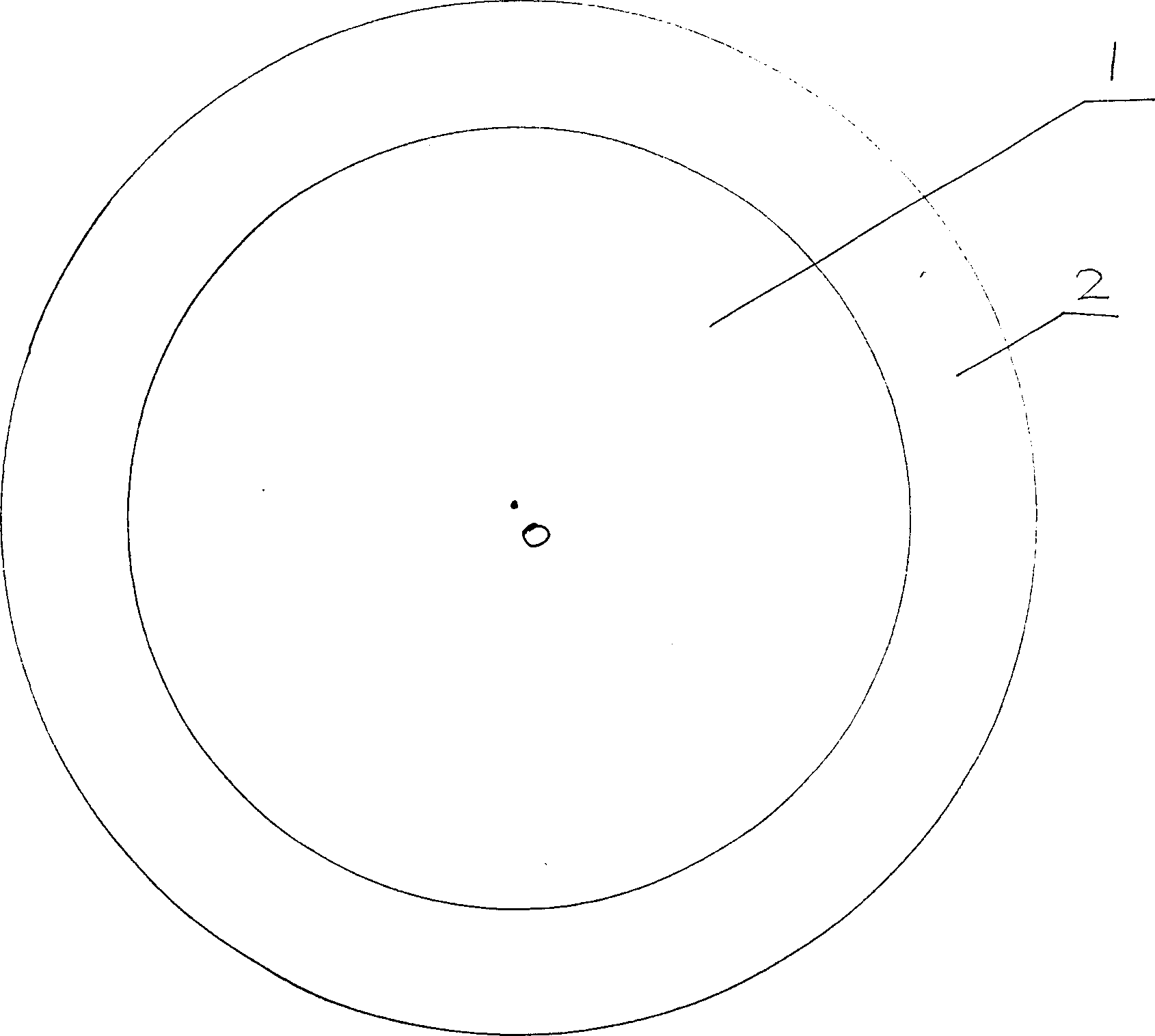

[0033] The manufacturing method of technical ceramic vessel of the present invention comprises the steps: a, making the disk mud blank that shape is the body of revolution in batches, and section shape is as follows figure 1 As shown, the mud is then sent into the kiln for sintering to form a plurality of disc ceramic plain bodies with the same shape; The lower surface of the tire is determined as a part that does not need to be patterned, and the upper surface of each disc ceramic plain tire is divided into two regions, wherein the shape of the middle region 1 is a circle, and the shape of the outer edge region 2 is approximately a ring shape, the center point O of the circle overlaps with the center point of the circular ring and is located on the central axis of the ceramic plain tire of the rotary body, such as figure 2As shown; c, design according to the shape of the above two areas 1 and 2 and manually draw the surface pattern of the vessel, take a picture of the drawn ...

Embodiment 2

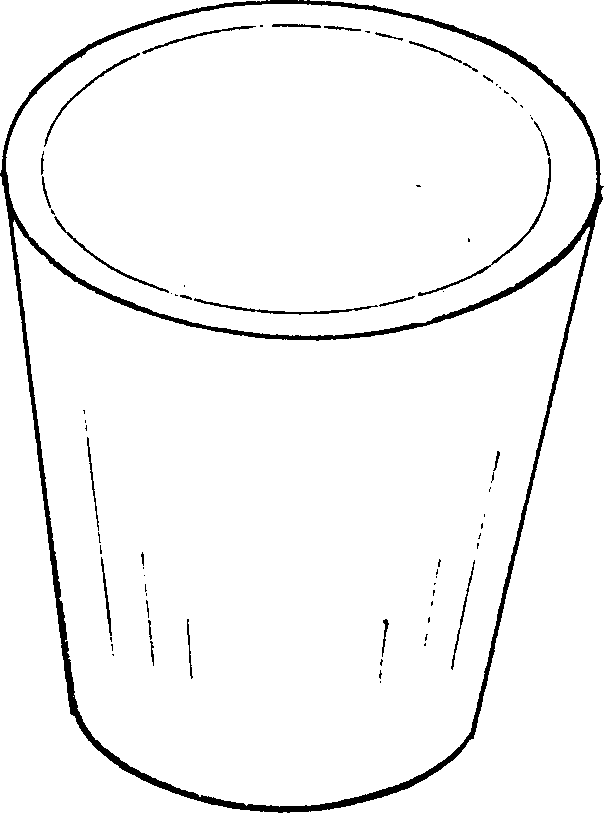

[0035] The manufacturing method of the technical ceramic vessel of the present invention is as follows: a, make the shape in batches and be the conical shape flowerpot mud blank of rotary body, then send the mud blank into the kiln for biscuit firing, form a plurality of ceramic plain tires with the same shape, the shape is as follows: image 3 Shown; b, the outer side of the frustum-shaped flowerpot mud blank is divided into the position that needs to form the pattern, and the rest of the positions are the parts that do not need to form the pattern, and the outer surface of the conical flowerpot mud blank is divided into an integral area, the The shape of the region is essentially a truncated cone, (such as Figure 4 The surface indicated by the middle arrow a), the central axis of the truncated cone is located on the central axis l of the ceramic tire of the revolving body; c, design and manually draw the surface pattern according to the shape of the above-mentioned outer sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com