Suspension catalyst distillation process for epoxidizing alkene directly

A technology of catalytic distillation and process method, which is applied in the field of direct epoxidation of olefins to prepare epoxy compounds, can solve the problems of temperature control dependence, high reaction pressure, complicated structure, etc., and achieves prevention of thermal decomposition of hydrogen peroxide, improvement of selectivity, and energy consumption. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

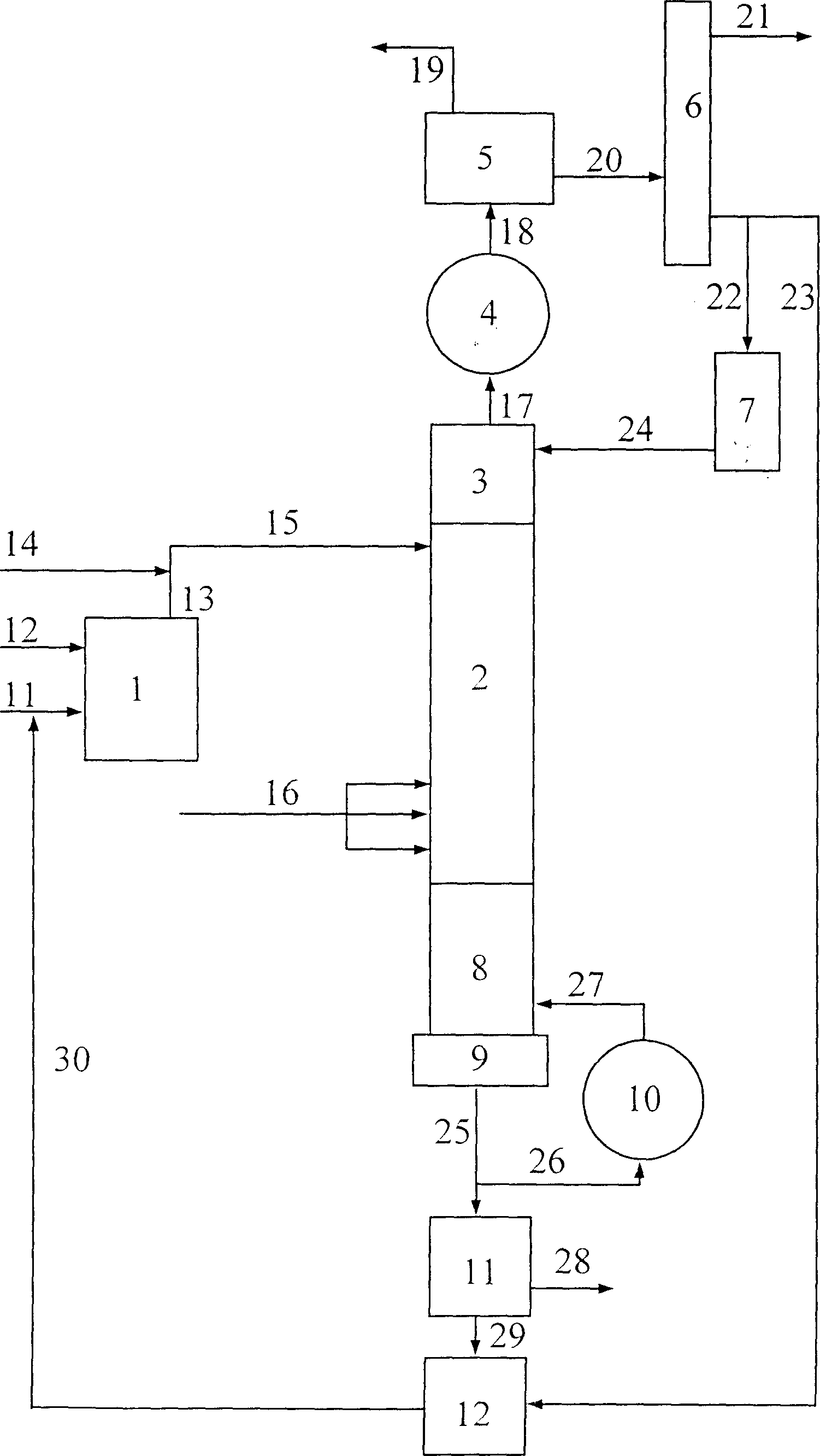

[0025]The powdery solid titanium-silicon molecular sieve catalyst and solvent are added to the catalyst storage tank, mixed evenly, and enter the tower together with hydrogen peroxide from the upper part of the reaction section of the tower, and flow countercurrently with the olefins entering the tower from the lower part of the reaction section in one or more ways during the descent process Touch and react. After the epoxides produced by the reaction, the remaining olefins and part of the solvent are vaporized by the heat released by the reaction, they enter the gas-liquid separator through the distillation section and the condenser, and the unreacted gas olefins are recycled after being deoxygenated. The liquid from the gas-liquid separator enters the distillation tower, the crude epoxy product comes out from the top of the tower, and the solvent comes out from the bottom of the tower, part of which flows back into the tower through the intermediate tank, and the other part g...

Embodiment approach 2

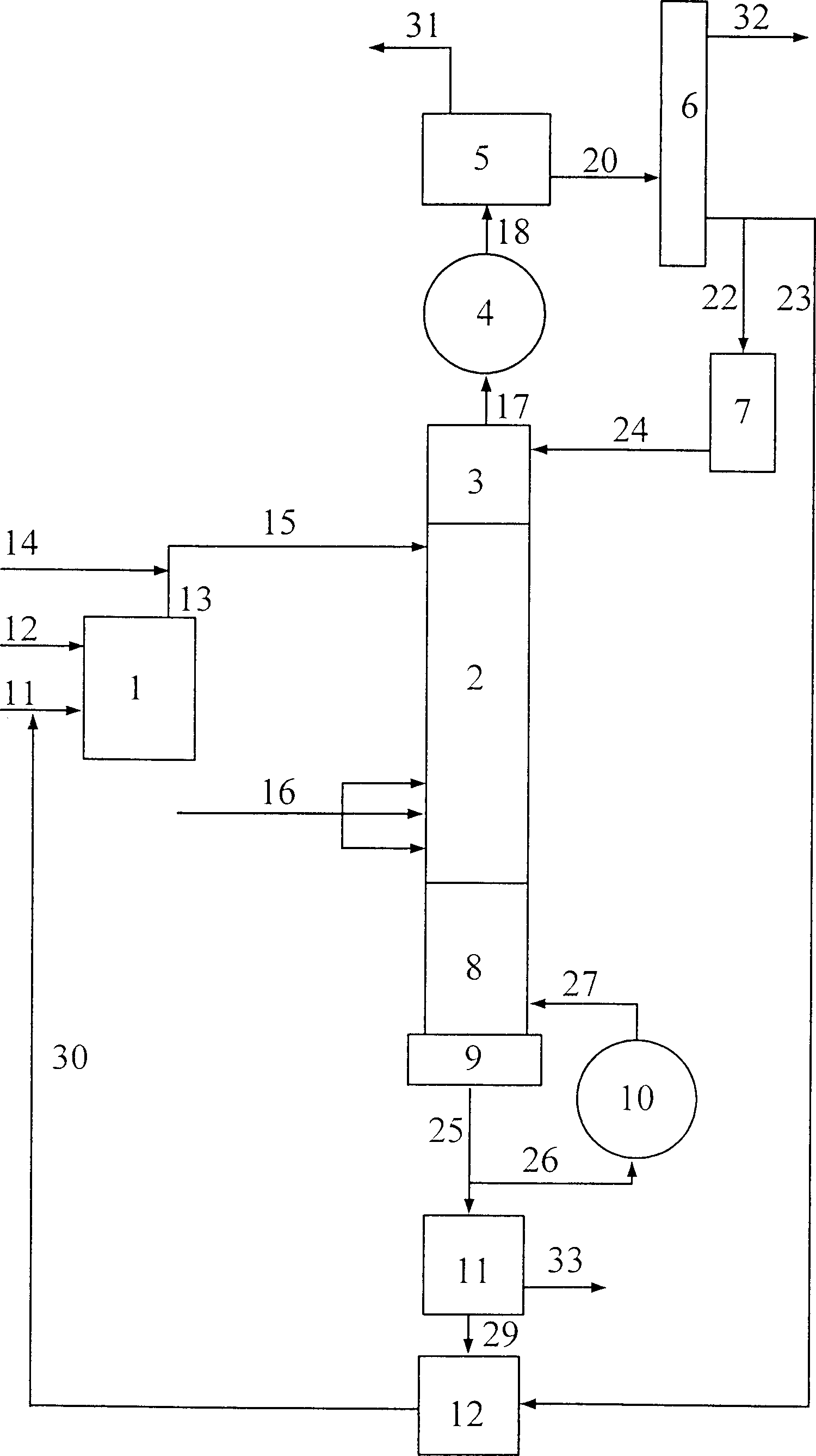

[0027] The powdery solid titanium-silicon molecular sieve catalyst and solvent enter the catalyst storage tank, and after being fully mixed, enter the tower together with hydrogen peroxide from the upper part of the reaction section of the tower. Contact and react in countercurrent. The remaining olefins and solvents in the reaction are vaporized by the heat released by the reaction, and enter the gas-liquid separator through the distillation section and condenser, and the separated non-condensable gas is emptied, and the liquid enters the distillation tower, and the unreacted olefins are discharged from the top of the tower for recycling A part of the solvent from the bottom of the tower is used as a diluent to go to the catalyst intermediate tank, and the other part is returned to the tower through the intermediate tank. The unvaporized material in the reaction section goes down into the stripping section, and all the olefins and solvents are taken out to enter the reaction ...

Embodiment approach 3

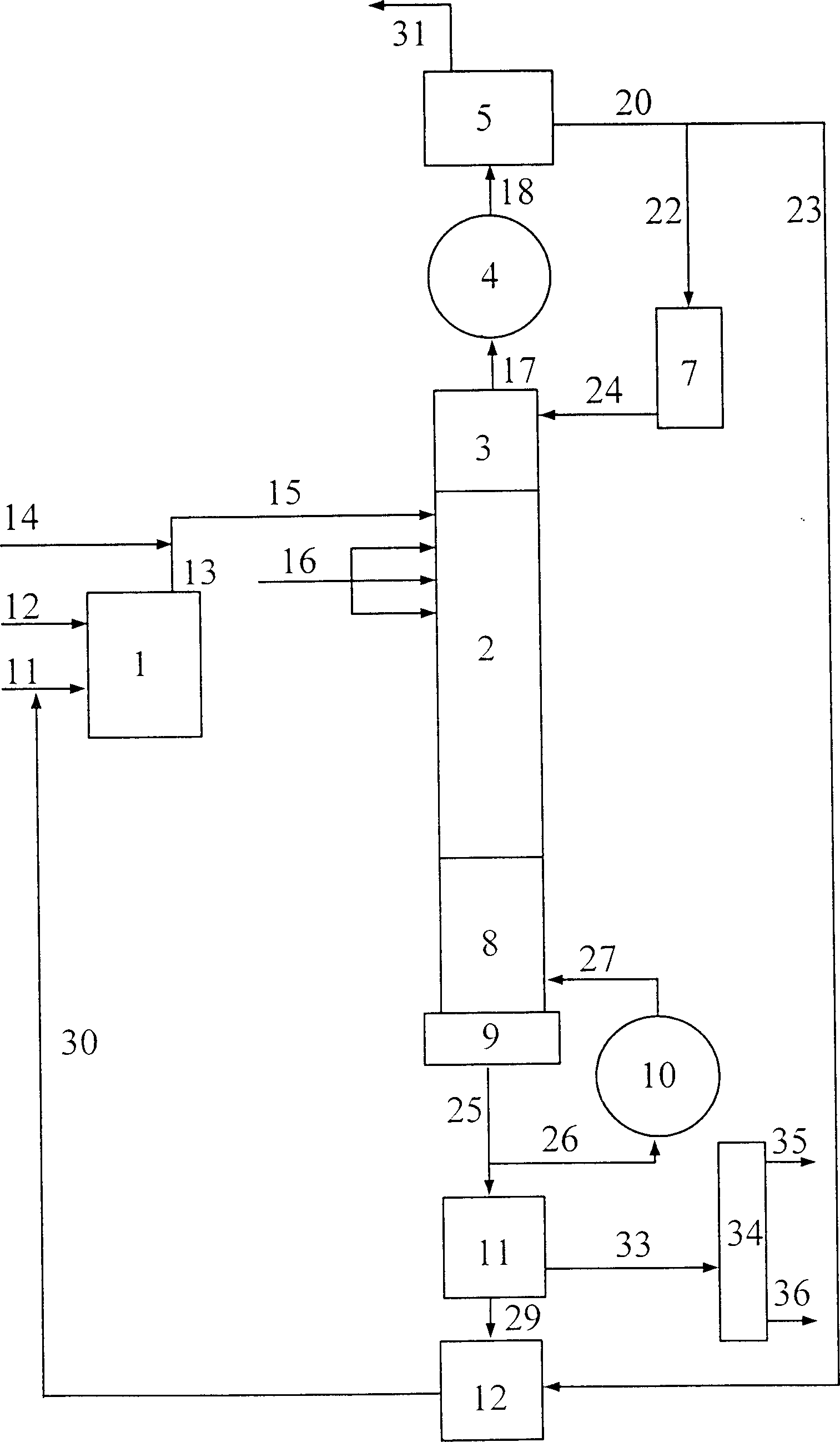

[0029] The powdered solid titanium-silicon molecular sieve catalyst and solvent enter the catalyst storage tank, and after being fully mixed, enter the tower from the upper part of the reaction section of the tower together with hydrogen peroxide; at the same time, olefins enter the tower from the upper part of the reaction section in one or more ways , and react with the catalyst. The material vaporized by the heat of reaction goes up into the distillation section, in which the olefin returns to the reaction section through fractionation, the solvent vapor enters the gas-liquid separator after being condensed by the condenser, the separated non-condensable gas is emptied, and part of the liquid solvent is refluxed through the intermediate tank to In the tower, the other part is used as diluent to go to the catalyst intermediate tank. The unvaporized material in the reaction section goes down into the stripping section, and all the solvent is returned to the reaction section. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com