Grinding cloth for directional processing

A technology of grinding cloth and liquid crystal molecules, which is applied in the field of grinding cloth and can solve the problems of easy denaturation, variability, and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

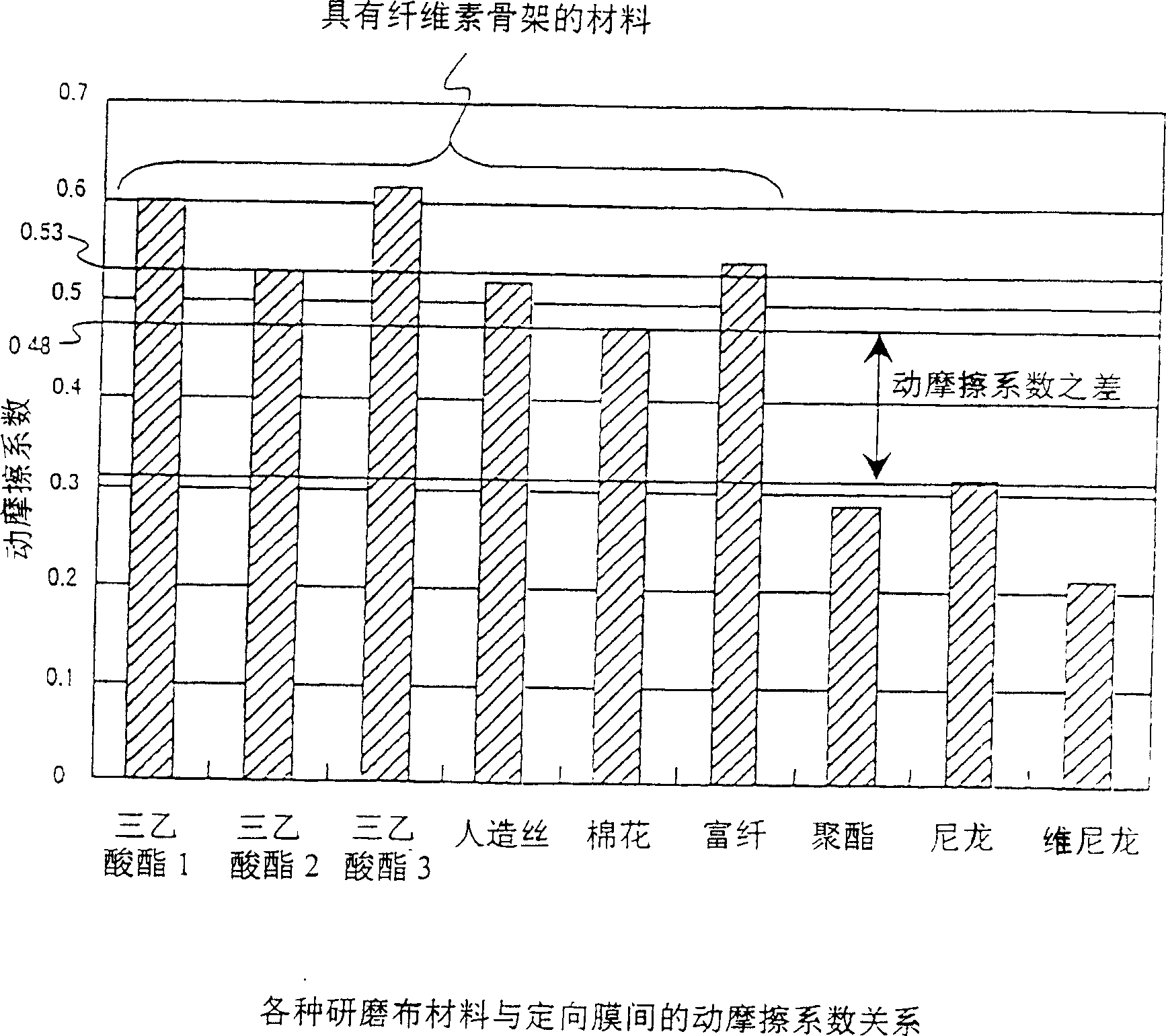

[0019] The inventors of the present invention used various fiber materials to try out abrasive cloths, and as a result of intensive research, it was found that by using acetate fibers in the fluff part, it is possible to obtain a cloth having the characteristics of large orientation adjustment force, high wear resistance, and low chargeability. The abrasive cloth, the following hereby specifically describes the present invention.

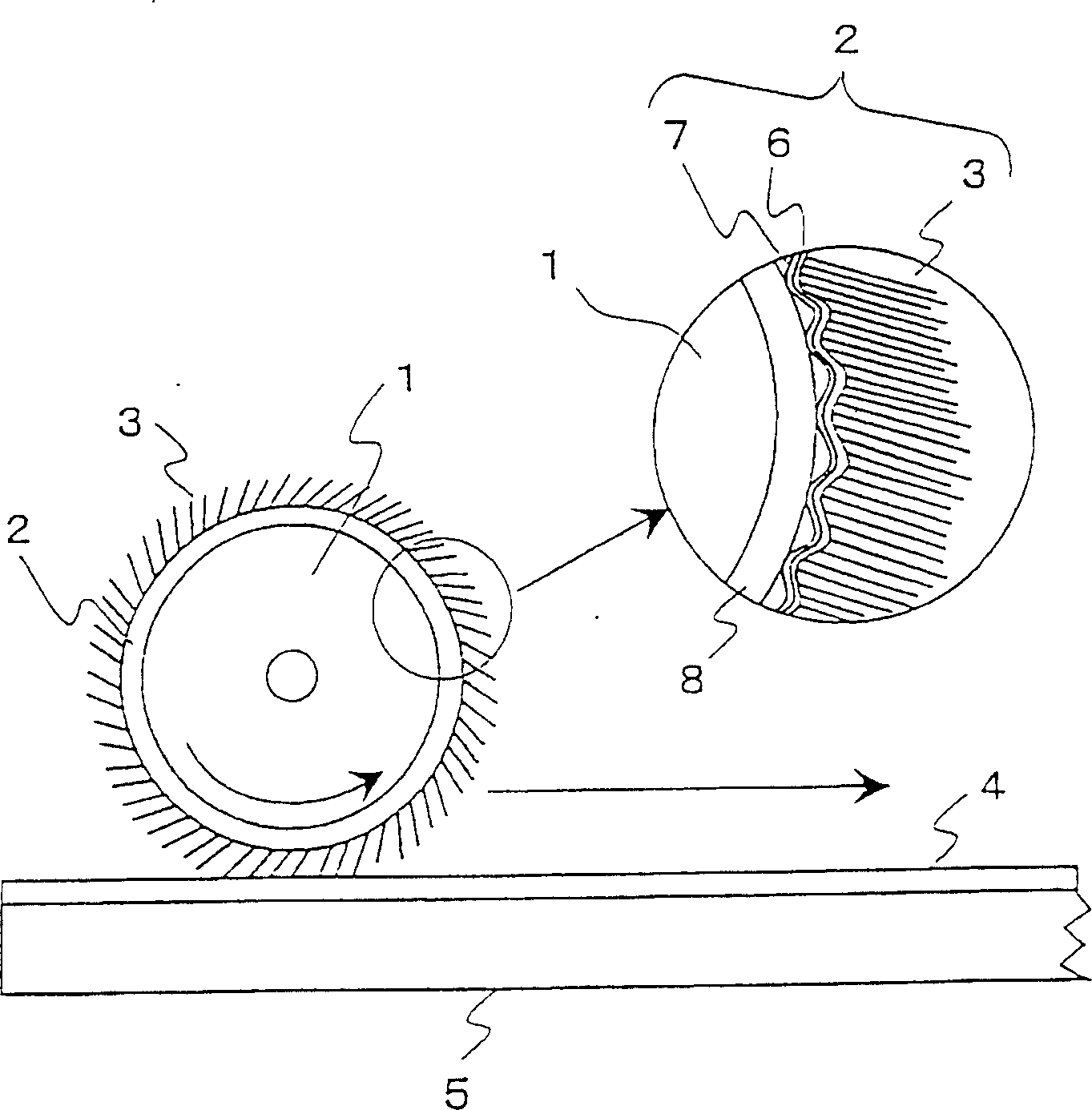

[0020] Such as figure 1 As shown, the abrasive cloth 2 of this embodiment is a raised cloth having piles 3 for raising fibers, a base fabric 6 for fixing them, and an undercoat layer 7 , and acetate fibers are contained in the pile yarns constituting the piles 3 .

[0021] Acetate fiber is a fiber made of cellulose acetate, which is cellulose acetate represented by the following chemical formula:

[0022] [C 6 h 7 o 2 (OCOCH 3 ) x (OH) 3-x ] n (where, 0

[0023] Among them, as long as it can be processed into a fibrous form, it does no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| friction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com