Lubricating oil composition for refrigerators and method for lubrication with composition

A technology for lubricating oil composition and refrigerator, applied in lubricating compositions, chemical instruments and methods, petroleum industry, etc., can solve the problems of poor wear resistance, poor sealing performance, and the inability of long-term stable use of refrigerants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7 and proportion 1、2

[0075] (1) Lubricating oil composition for refrigerators

[0076] 70% (weight) of the refrigerant composed of a propane-isobutane mixture with a molar ratio of 1:1 and 30% (weight) of the base oil of the properties shown in Table 1 were mixed respectively to prepare Examples 1 to 7 and comparative Lubricating oil compositions for refrigerators of Examples 1 and 2. Using this lubricating oil composition for refrigerating machines, an actual machine test was carried out in the following manner to evaluate its performance. The results are shown in Table 1.

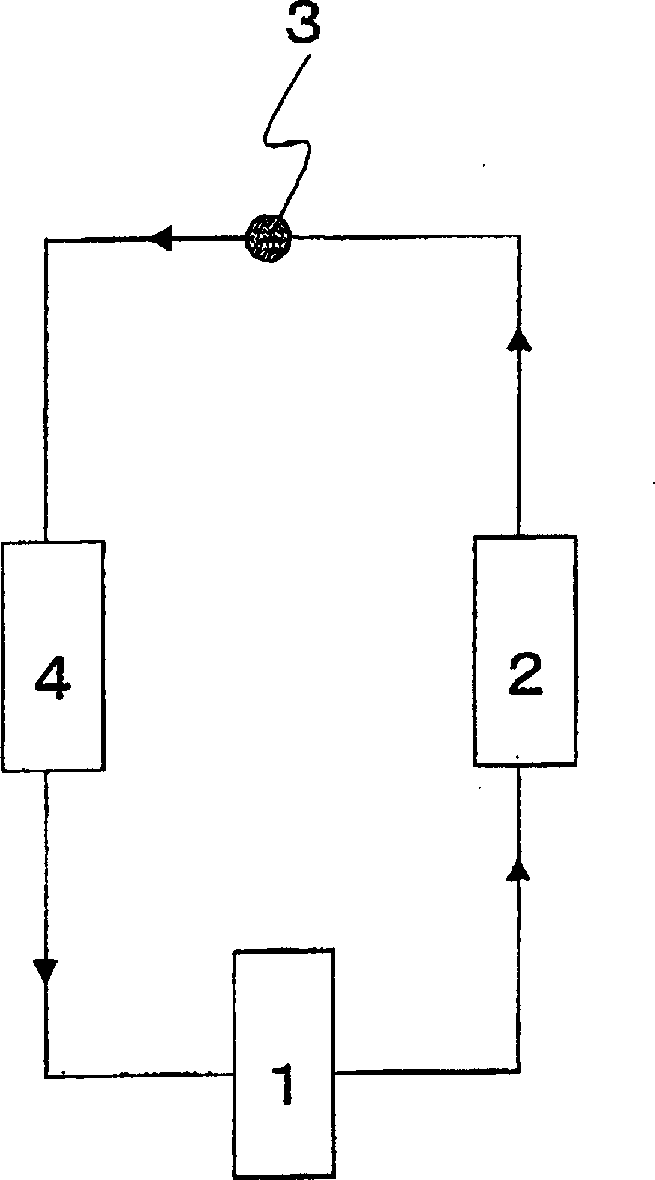

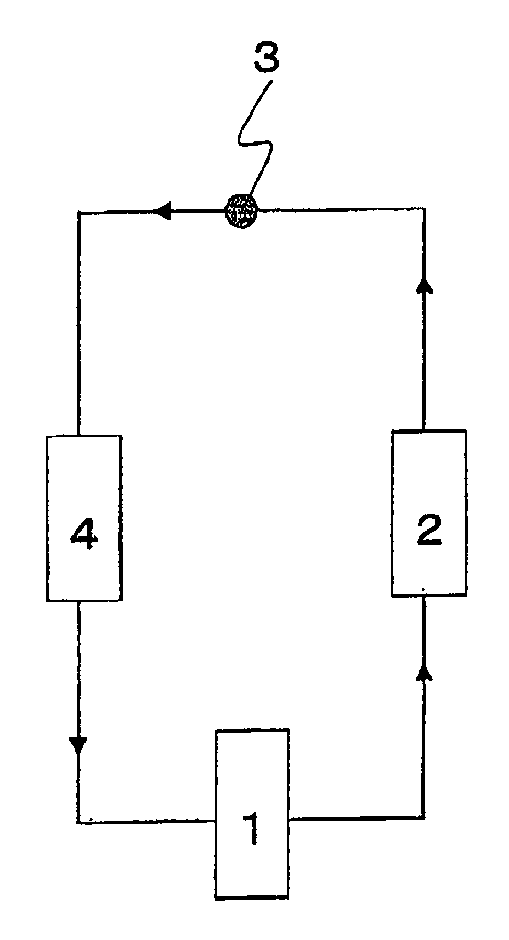

[0077] (2) Compressor refrigeration cycle mode

[0078] As the refrigerator, a compressor refrigeration cycle composed of a general "compressor-condenser-expansion valve-evaporator" is used. Among them, a capillary expansion valve can be used as the expansion valve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com