Electricity generating apparatus of comprehensive using rotating furnace gas and waste heat of steam

A converter gas and steam generator technology, applied in the converter field, can solve the problems of not being able to drive generators to generate electricity, high manufacturing costs, difficult operation, maintenance and repair, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

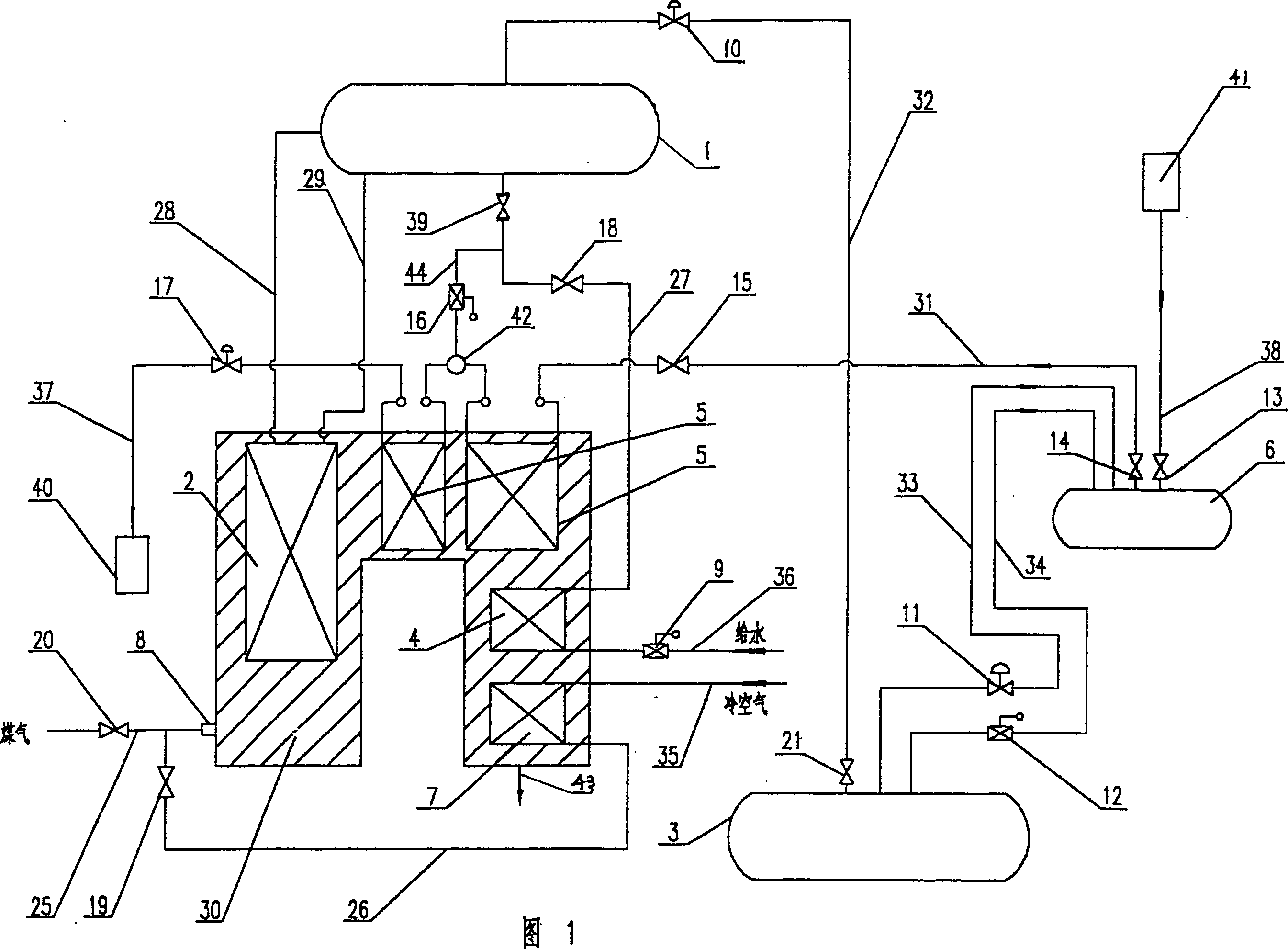

Image

Examples

Embodiment

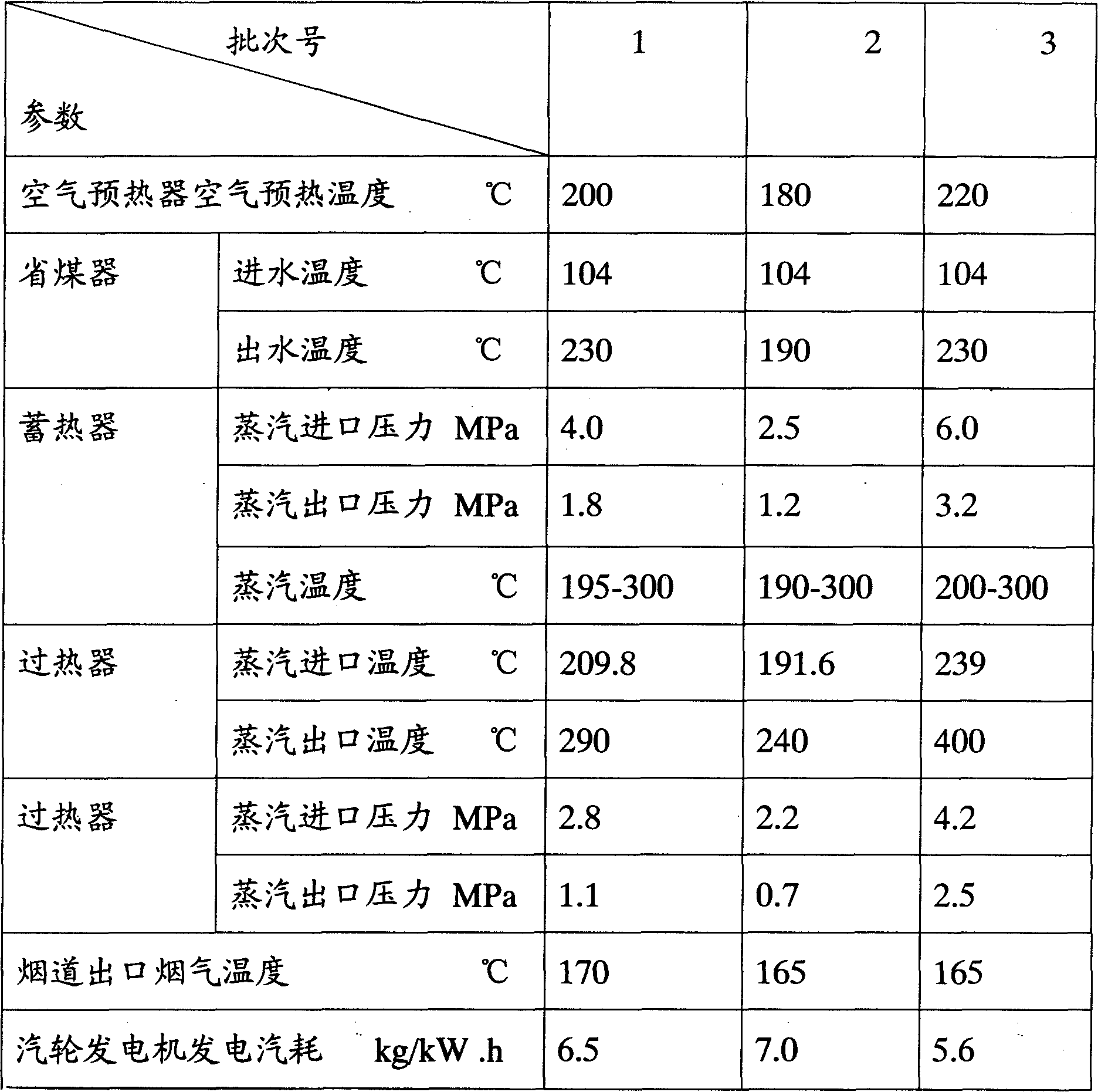

[0020] According to the power generation device for comprehensive utilization of converter gas and waste heat steam according to the present invention, and the above-mentioned specific implementation process, three tests were carried out, and the relevant parameters of the three tests are shown in Table 1. The temperature of the accumulator changes during the process of heat storage and heat release, so in the three tests, this parameter is a range.

[0021] Table 1 Relevant specific parameters of the three tests of comprehensive utilization of converter gas and waste heat steam for power generation

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com