Process for preparing nm-class superfine vanadium carbide powder

A nano-scale, vanadium carbide technology, which is applied in the field of carbide powder preparation, can solve the problems that cannot meet the production requirements of ultra-fine grains, and achieve the effects of narrow particle size distribution, increased carbonization reaction speed, and uniform particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

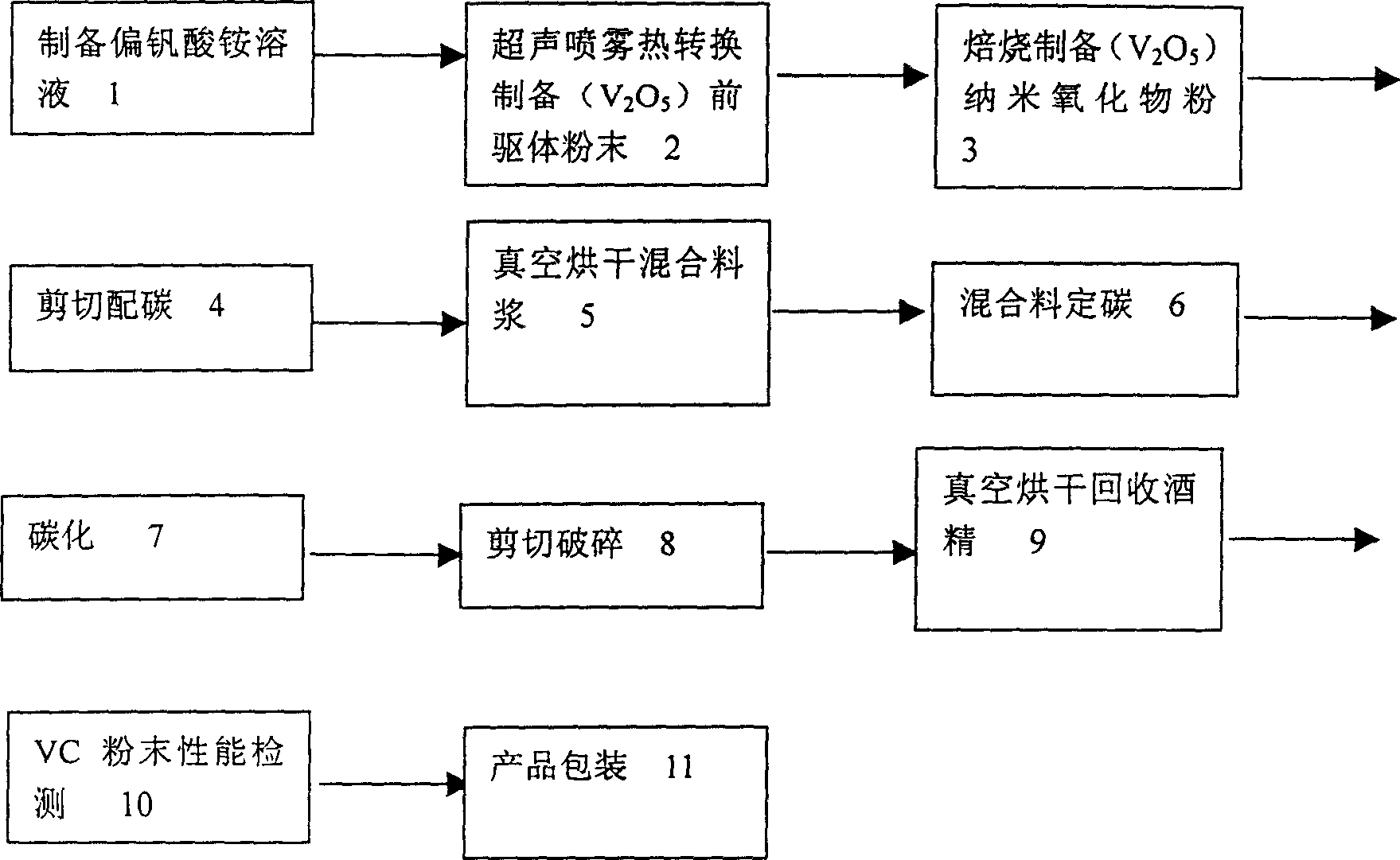

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: When preparing 1kg nano (VC) powder, complete according to the following steps.

[0034] 1. Preparation of NH 4 VO 3 aqueous solution

[0035] Weigh 1.864kg NH 4 VO 3 powder by NH 4 VO 3 :H 2 The mass ratio of O=1:46 was added to 85.74Kg of distilled water, heated to 85°C, and stirred. Make it fully dissolved and prepare 87.6Kg NH 4 VO 3 Aqueous solution (dispensing into small jars is permitted).

[0036] 2. Ultrasonic spray thermal conversion preparation V 2 o 5 Precursor powder.

[0037] In the ultrasonic spray heat conversion tower, the (NH 4 VO 3 ) aqueous solution, pour it into an atomization tank with heat preservation at 85°C, and carry out ultrasonic spray conversion powder production. The atomization process parameters are jet (air) pressure 2.0MPa, nozzle angle α=30°, liquid flow rate 195ml / min, and hot air temperature 120°C , can get nanoscale ultrafine (V 2 o 5 ) precursor powder.

[0038] 3. Roasting (V 2 o 5 ) precursor po...

Embodiment 2

[0055] Embodiment 2: When preparing 10kg nanometer (VC) vanadium carbide powder, complete according to the following steps.

[0056] 1. Preparation of NH 4 VO 3 aqueous solution

[0057] Weigh 18.64kg NH 4 VO 3 Powder, by NH 4 VO 3 :H 2 Add O=1:46 mass ratio 3 into 857.4Kg distilled water, heat to 90°C, and stir. Make it fully dissolved and prepare 876.4KgNH 4 VO 3 Aqueous solution (sub-package into small tanks is allowed).

[0058] 2. Ultrasonic spray thermal conversion preparation V 2 o 5 Precursor powder.

[0059] In the ultrasonic spray heat conversion tower, the (NH 4 VO 3 ) ammonium metavanadate aqueous solution, pour it into an atomization tank with a heat preservation temperature of 90°C, and perform ultrasonic spray conversion. With a flow rate of 205ml / min, nano-scale ultra-fine (V 2 o 5 ) precursor powder.

[0060] 3. Roasting (V 2 o 5 ) precursor powder

[0061] In a stainless steel tube furnace, the V 2 o 5 V 2 o 5 Nanoscale microcrystalli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com