Catalytic reforming and catalytic dehydrogenation fixed bed radial reactor

A catalytic dehydrogenation and catalytic reforming technology, which is applied in catalytic cracking, chemical instruments and methods, cracking, etc., can solve the unsuitable requirements of catalytic reforming and catalytic dehydrogenation, and does not solve the problem of sparger control pressure drop, reactor Complicated internal structure and other issues to achieve the effects of avoiding heat loss, uniform axial temperature, and reducing pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

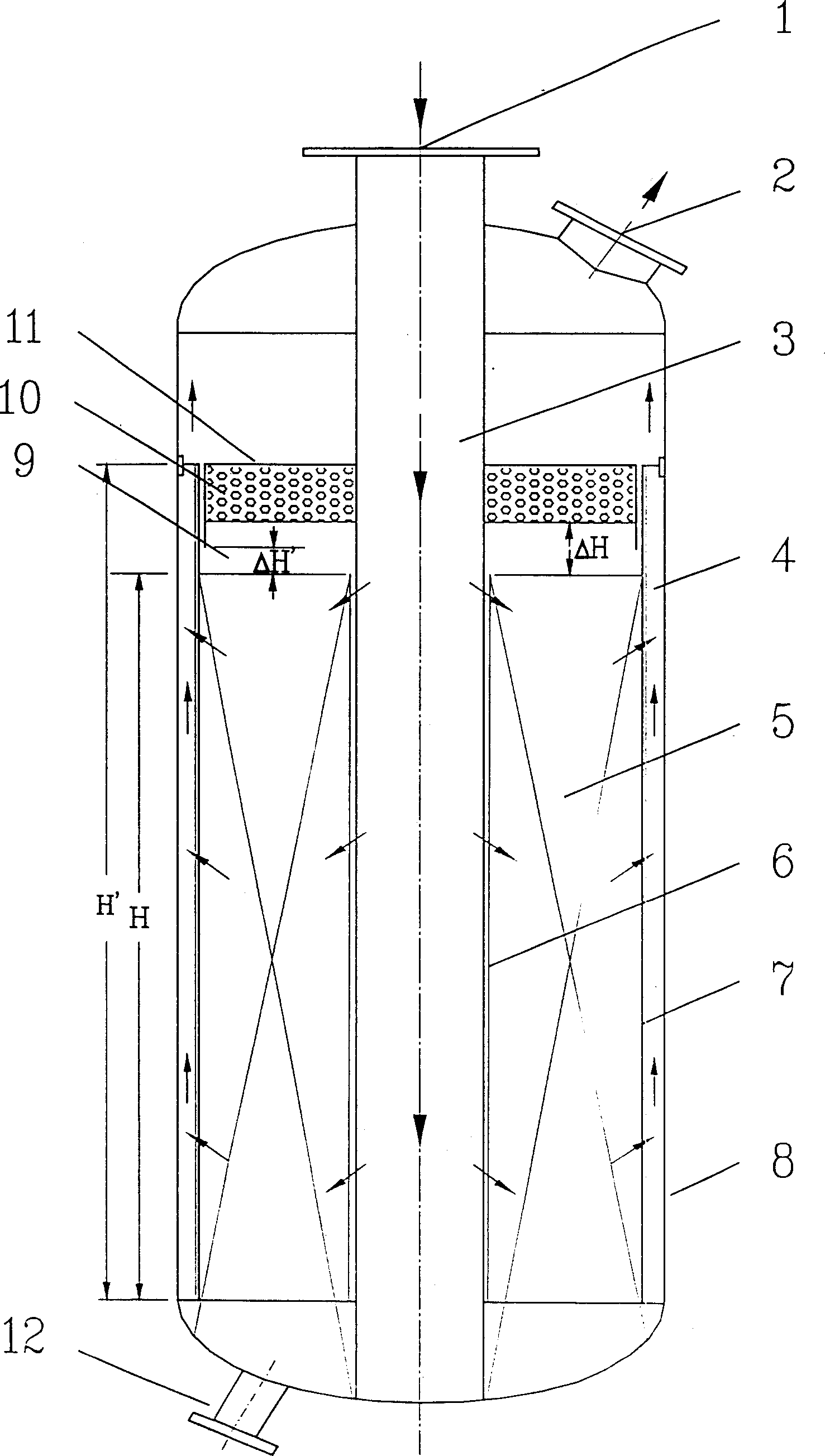

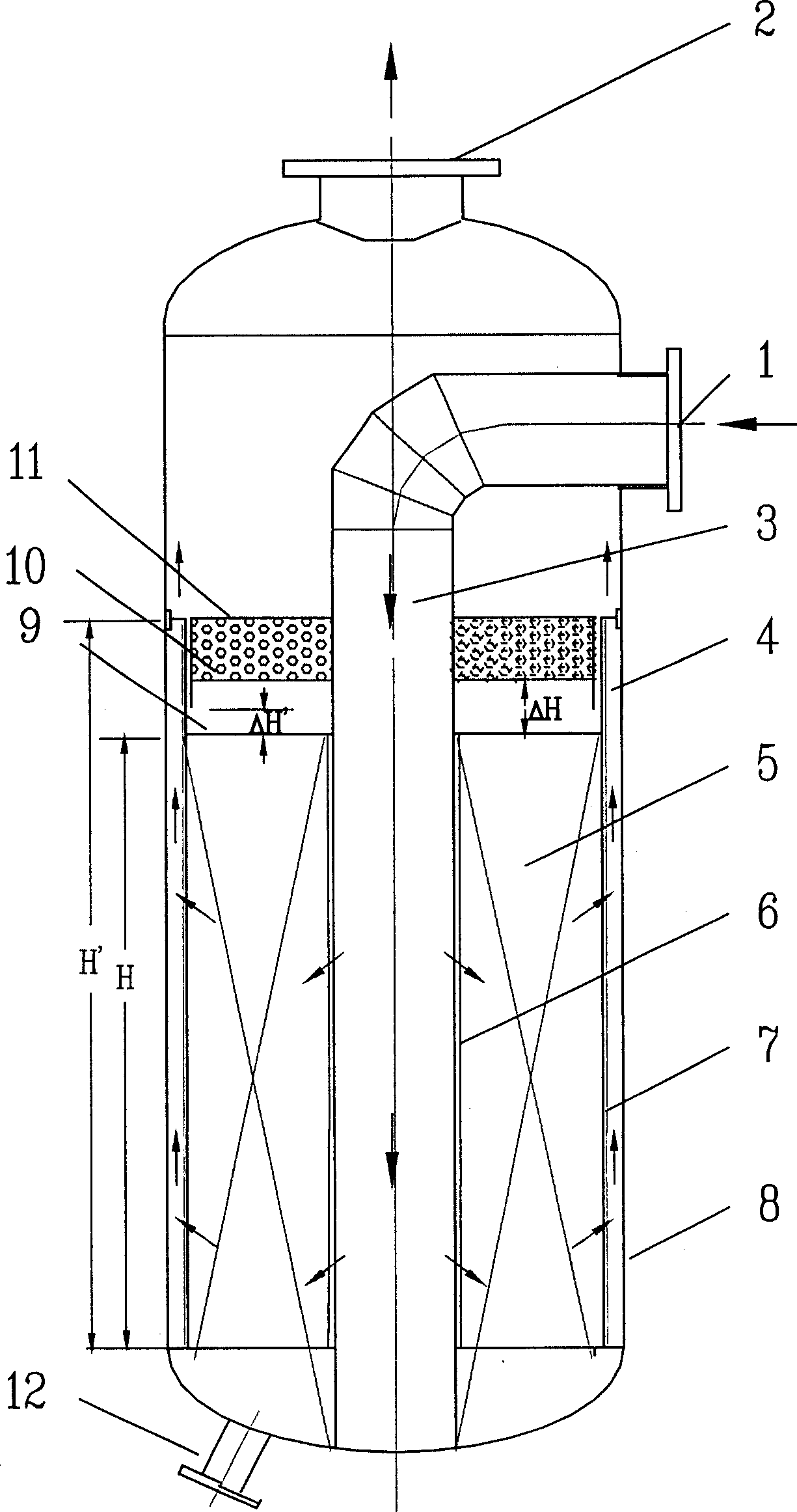

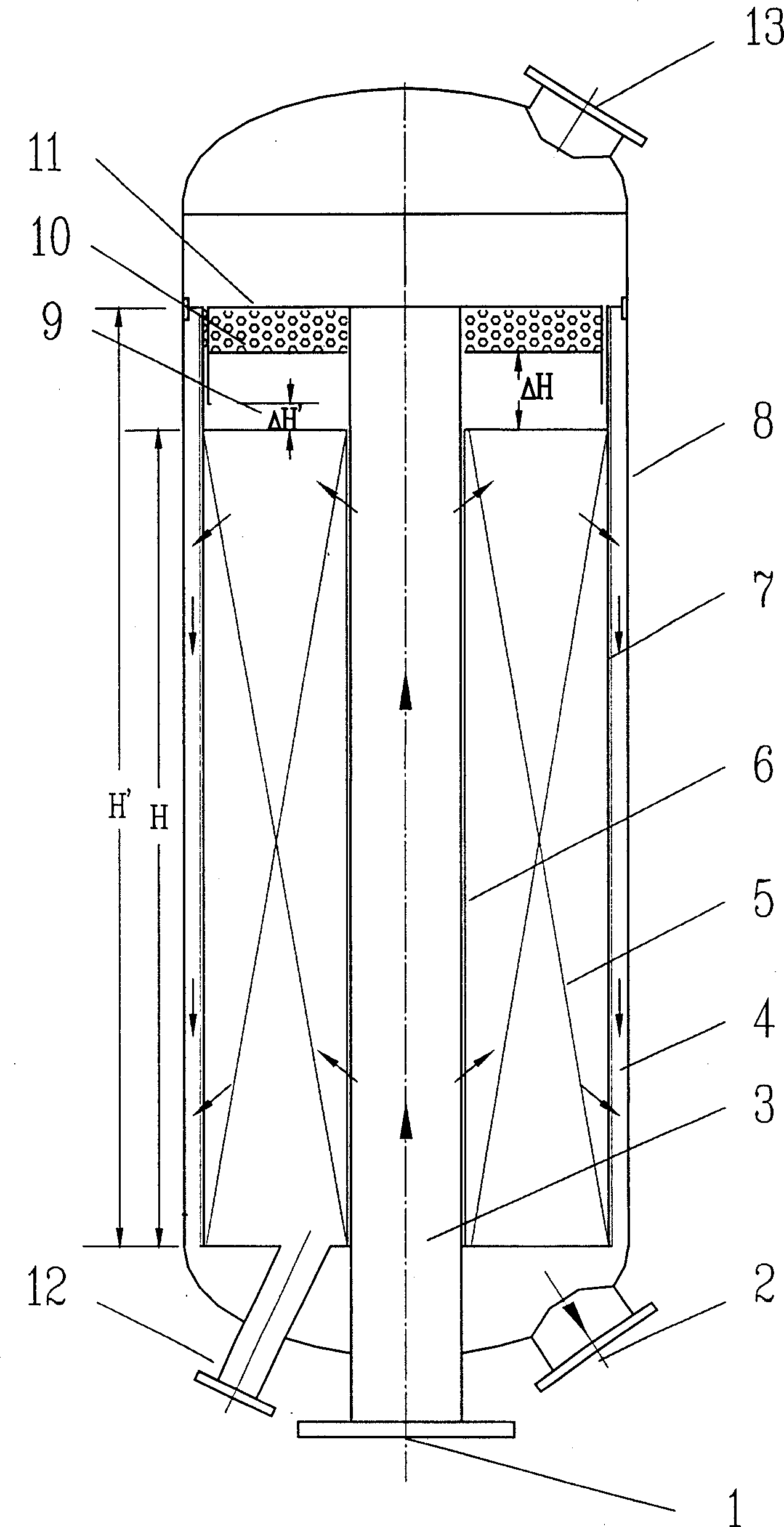

[0068] Example 1 The molar ratio of hydrogen to hydrocarbons in the raw material is 6-10, and the weight-to-liquid space velocity is 1.0-3.0h -1 , The semi-regenerative catalytic reforming reaction process with a reaction temperature of 450-550°C and a reaction pressure of 1.2-3.0MPa can be used figure 1 , figure 2 or image 3 Any one of the three ways shown.

Embodiment 2

[0069] Example 2 H in the raw material 2 The molar ratio of O / ethylbenzene is 8~10, and the liquid space velocity of ethylbenzene is 0.35~0.45h -1 , The ethylbenzene dehydrogenation reaction process with a reaction temperature of 550-645°C and a reaction pressure of 45-80Kpa (absolute pressure) can be used figure 1 , figure 2 or image 3 Any one of the shown reactors can be implemented.

[0070] The reaction gas enters the split flow channel 3 formed by the inner porous wall cylinder 6 from the reaction gas inlet 1, flows radially into the radial bed area 5 through the inner distribution holes 15 on the inner porous wall cylinder 6, and then passes through the outer porous wall from the inside to the outside. 7 enters the reaction gas collecting channel 4 for centrifugal flow, and the reaction gas flows in the opposite direction in the collecting channel 4 and the split channel 3, and then flows out through the outlet 2 of the reaction gas along the collecting channel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com