Preparation method of tunnelling oxidized layer in imbedded type quick flash storage

A technology for tunneling oxide layer and memory, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of tunnel oxide layer thickness limitation, affecting device reliability, unrealistic process technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

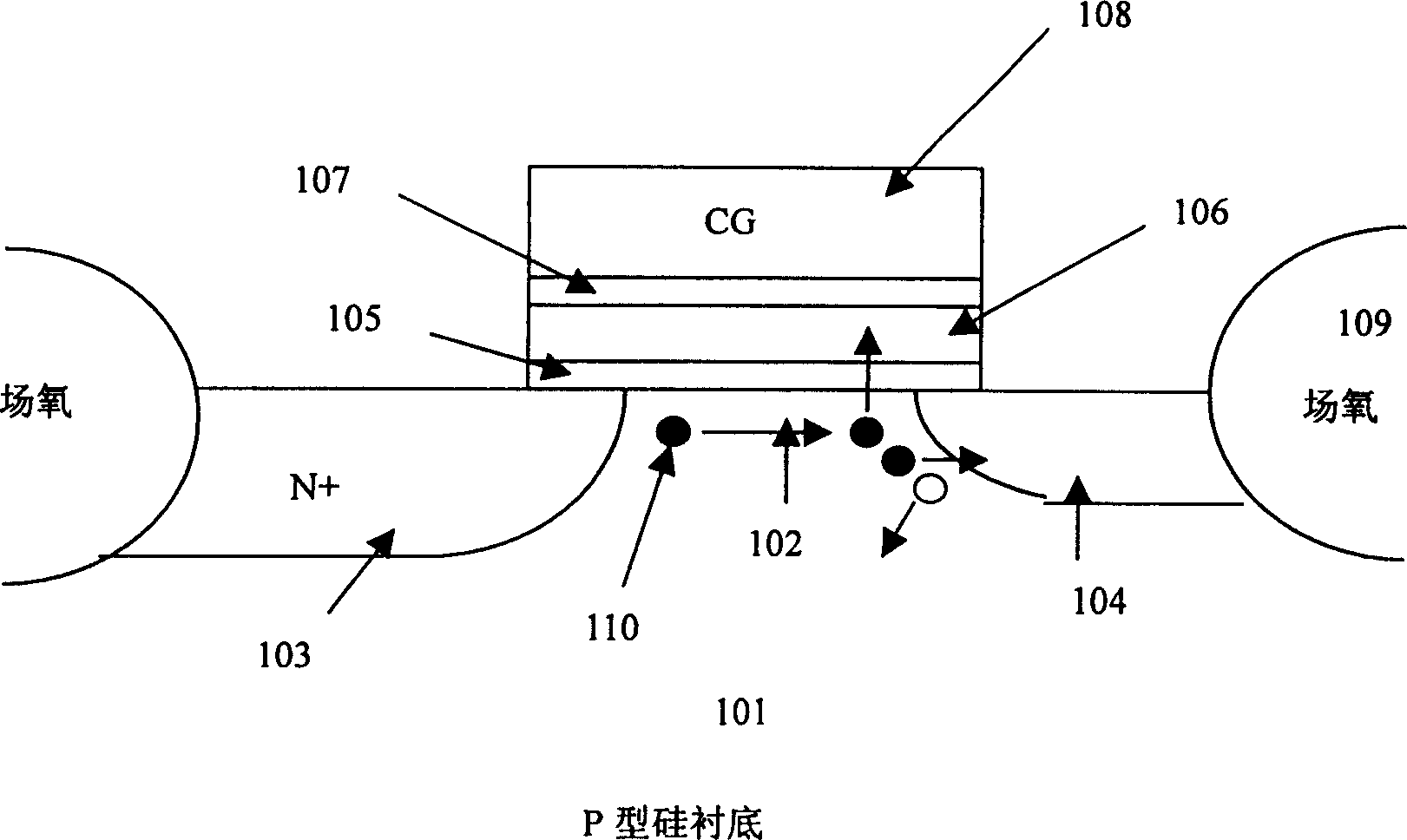

[0017] see figure 1 As shown, a method for preparing a tunnel oxide layer in an embedded flash memory of the present invention is characterized in that the method includes the following steps,

[0018] 1) First, the silicon wafer 101 on which the tunneling oxide layer 105 is to be grown is cleaned, and the cleaning solution is No. 1 cleaning solution and No. 2 cleaning solution (which is the prior art);

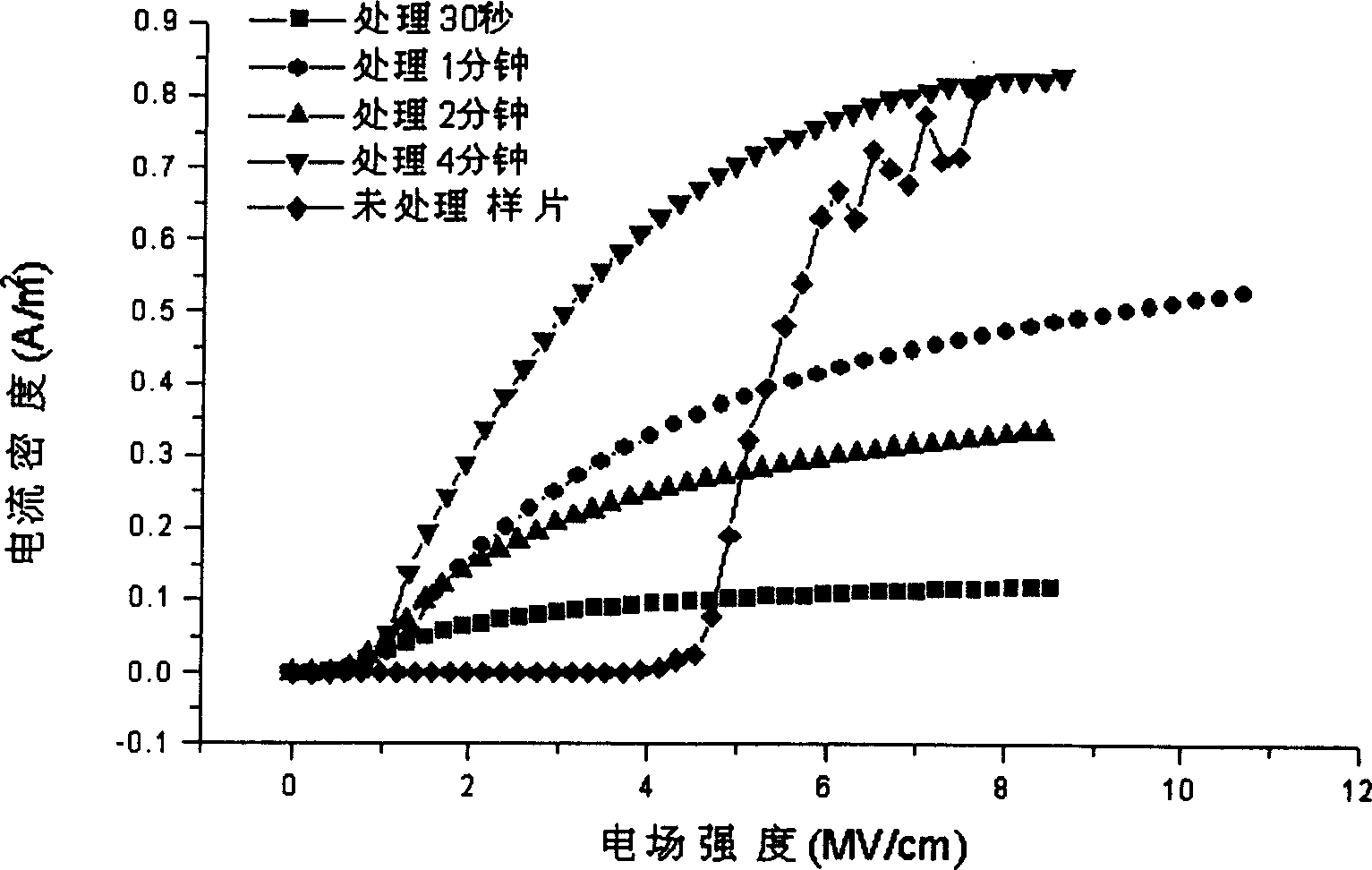

[0019] 2) Then use a dry etching machine to carry out fluorination treatment on a dry etching machine, under a pressure of 500mTorr, pass 100SCCM CF 4 Gas flow rate, the gap height between the upper and lower electrodes of the dry etching machine is 1.1cm, the power is 10W, and the time is 1-2 minutes;

[0020] 3) After the treatment, the silicon wafer 101 is cleaned conventionally, and then cleaned in isopropanol cleaning solution for 1 minute;

[0021] 4) Send the silicon wafer 101 into a high-temperature oxidation furnace for treatment, which is to oxidize at 850° C. for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com