Engine power generation device

A technology for power generation devices and engines, which is used in the control of generators, electrical controls, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

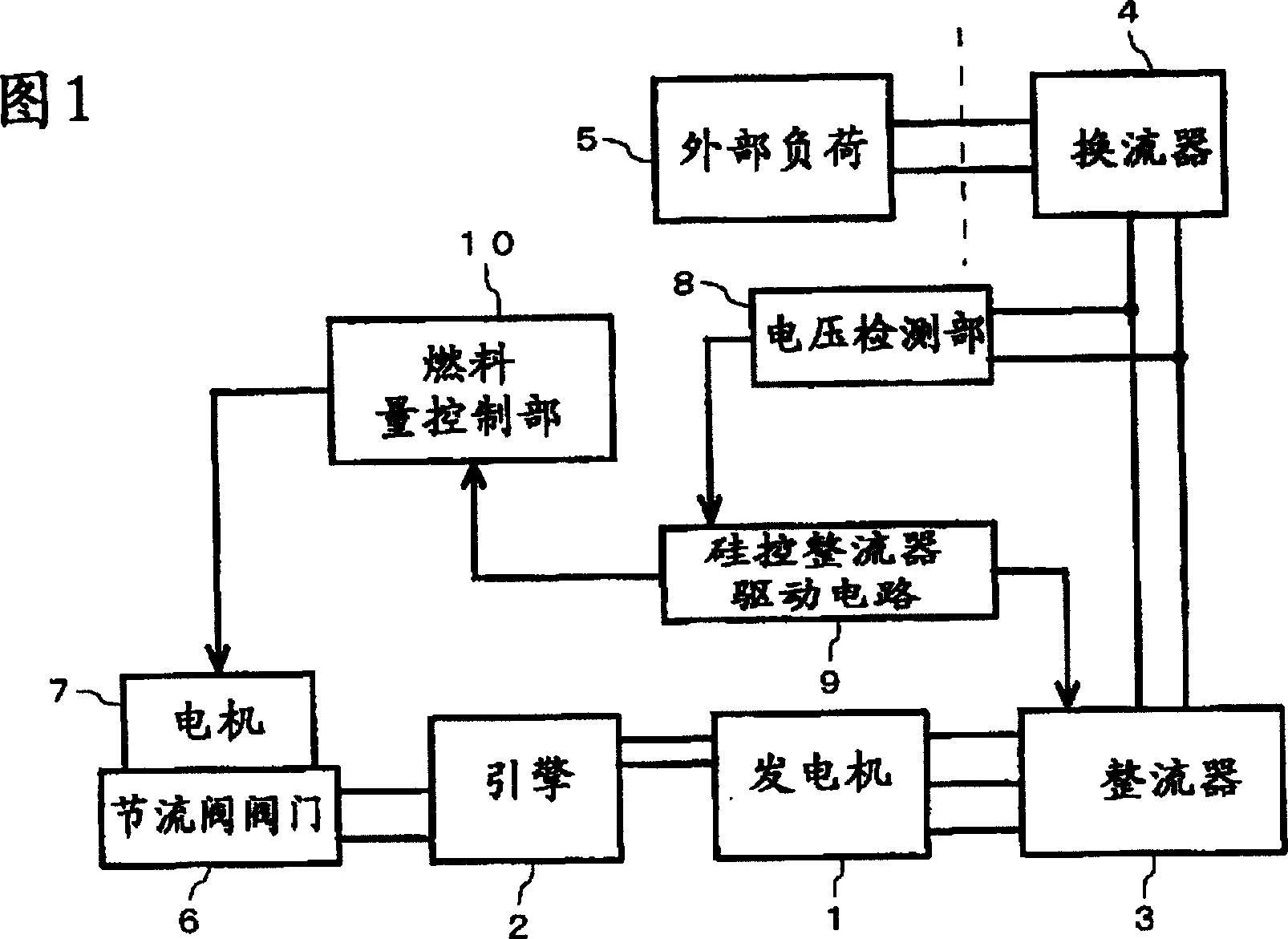

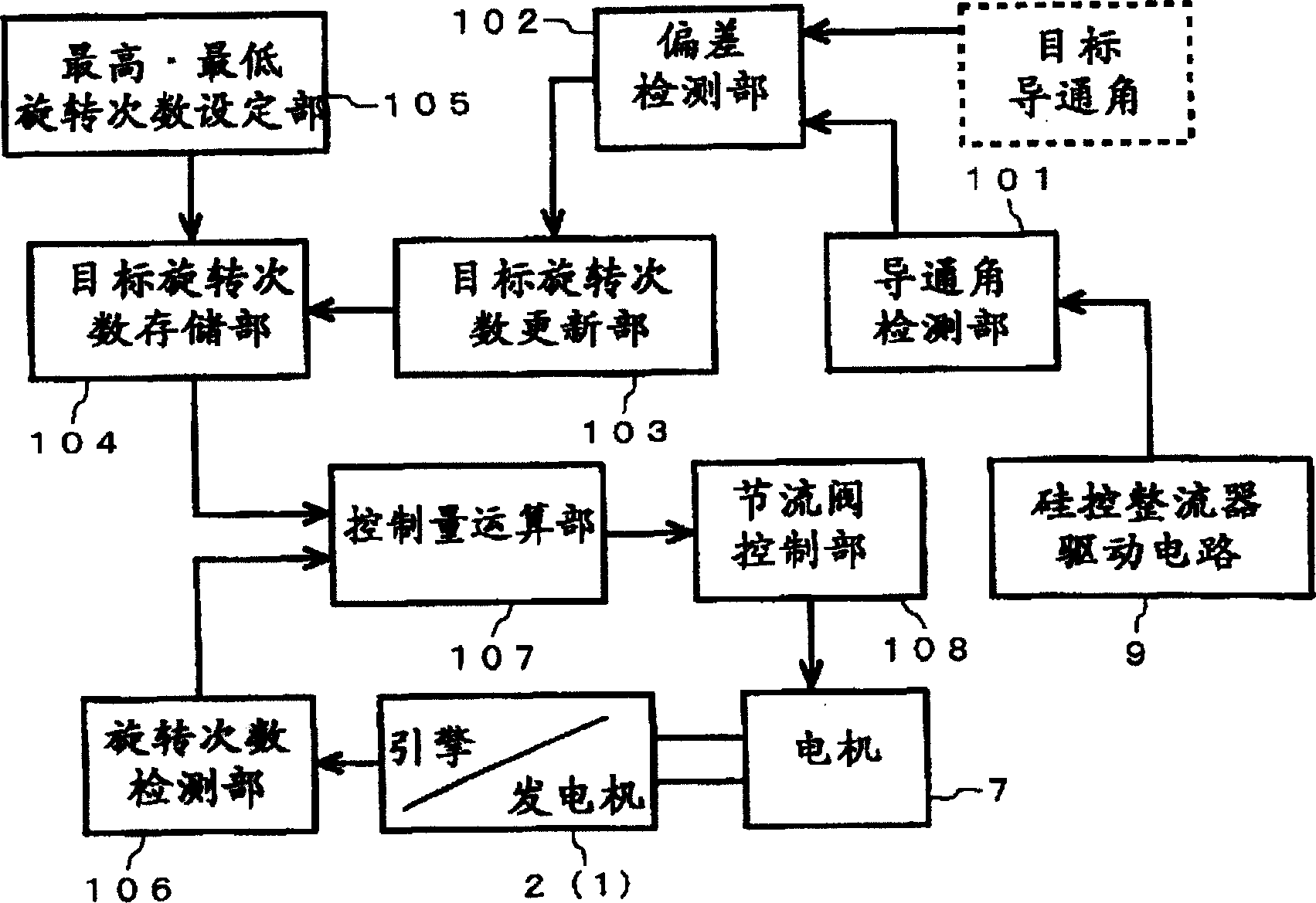

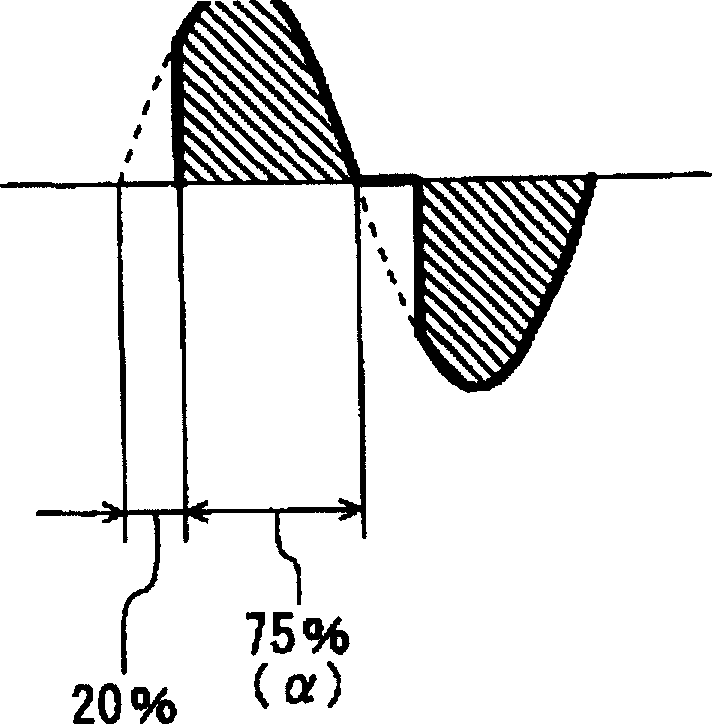

[0022] An embodiment of the present invention will be described in detail below with reference to the accompanying drawings. FIG. 1 is a block diagram showing the structure of an engine generator. A (internal combustion) engine 2 is connected to a magnetic multi-pole generator (hereinafter simply referred to as "generator") 1 with field flux provided by permanent magnets, which generator 1 is driven by the engine 2 to generate multi-phase (typically 3-phase )comminicate. This alternating current is converted into direct current by full-wave rectification through a rectifier 3 , which is composed of a rectifier circuit bridge-connected with a silicon controlled rectifier as a semiconductor rectifier element, and input to an inverter 4 . The inverter 4 supplies single-phase AC at a commercial frequency (for example, 50 Hz) to an external load 5 connected to its output side. In order to adjust the opening degree of the throttle valve of the engine 2, a stepper motor 7 is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com