Sequential ejection, rare combustion, fully electronic controlled diesel/natural gas dual-fuel engine

A dual-fuel engine and sequential injection technology, which is applied to combustion engines, machine/engines, internal combustion piston engines, etc., can solve the problems of scavenging short circuit, large valve overlap angle, and reduced thermal efficiency, etc., and achieve simple modification projects and fuel economy Good, good emission indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

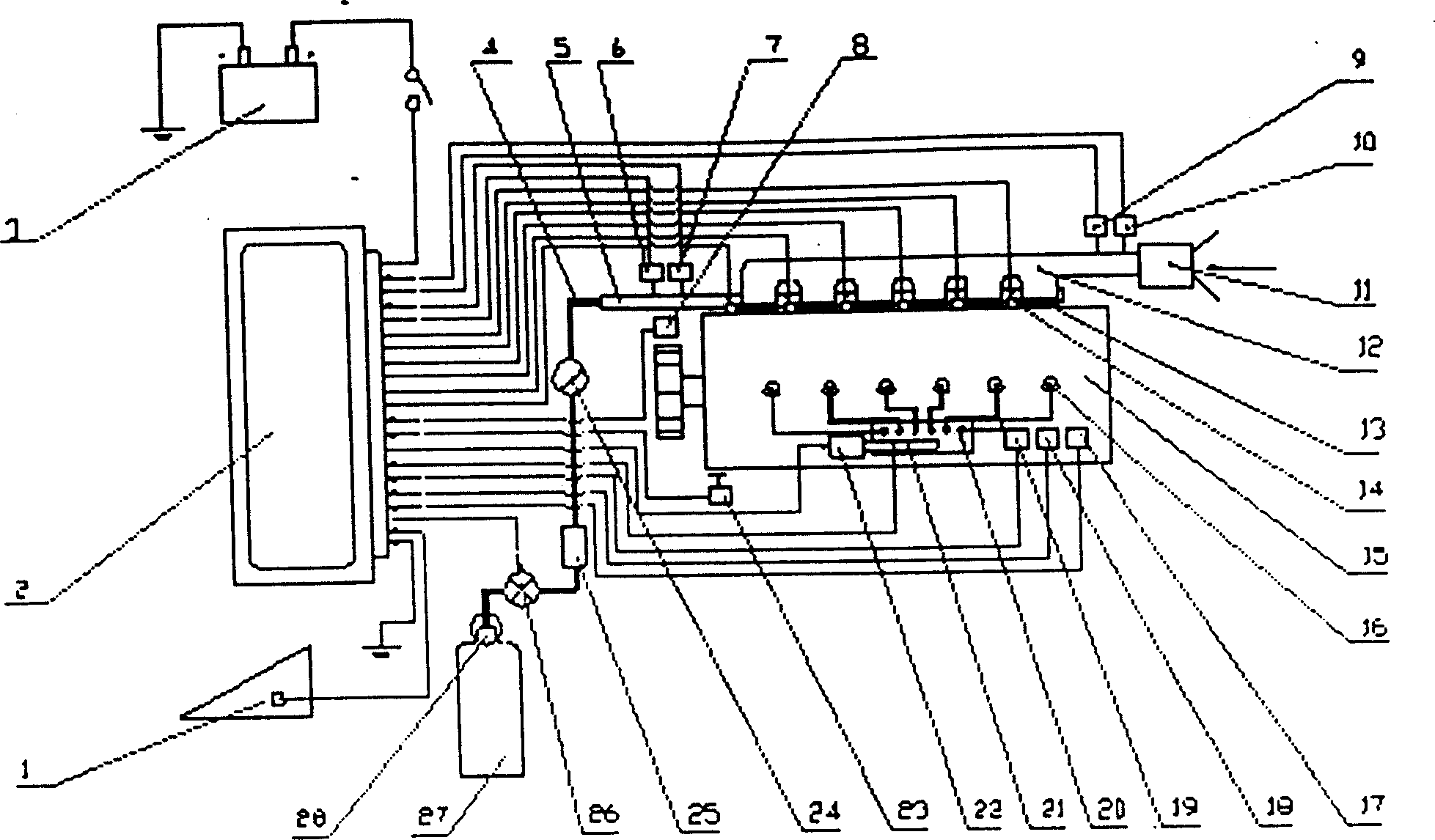

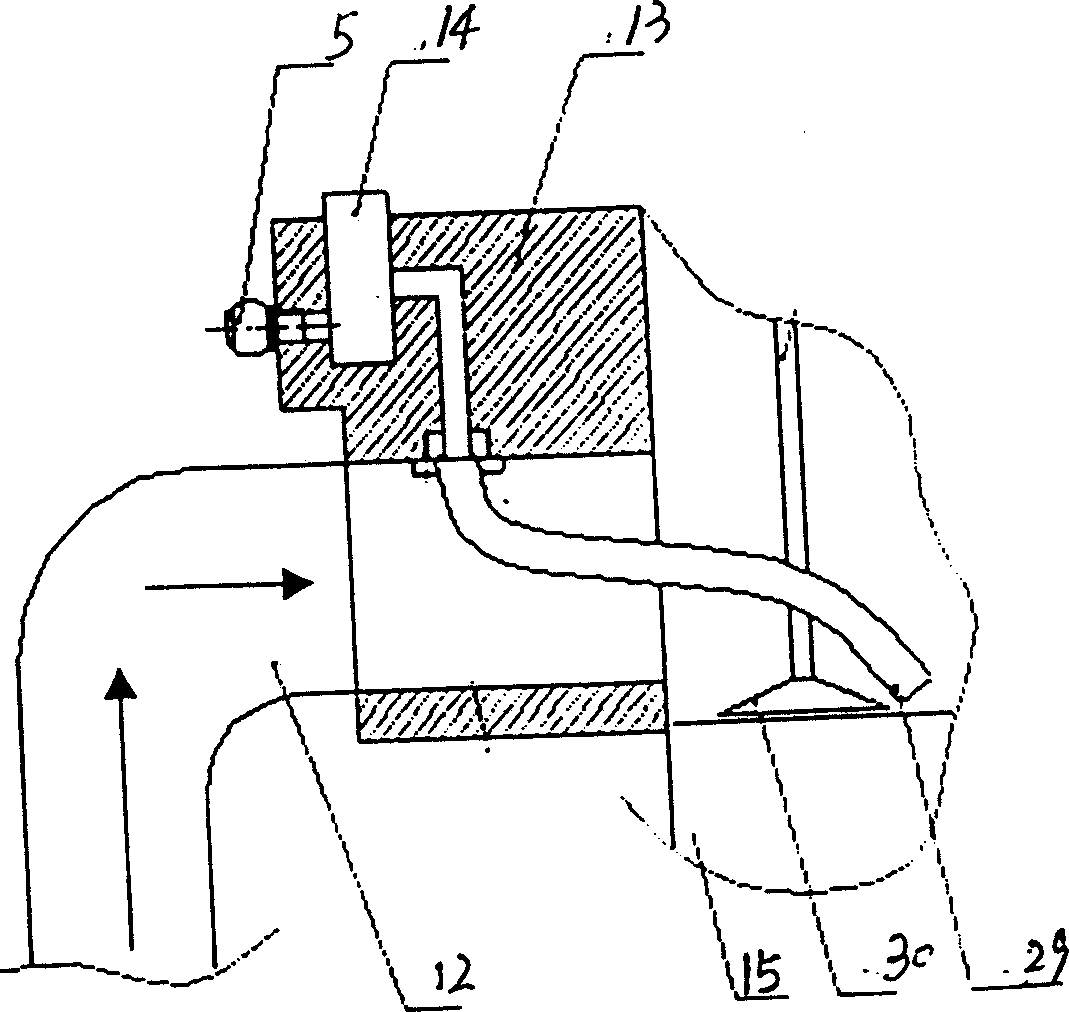

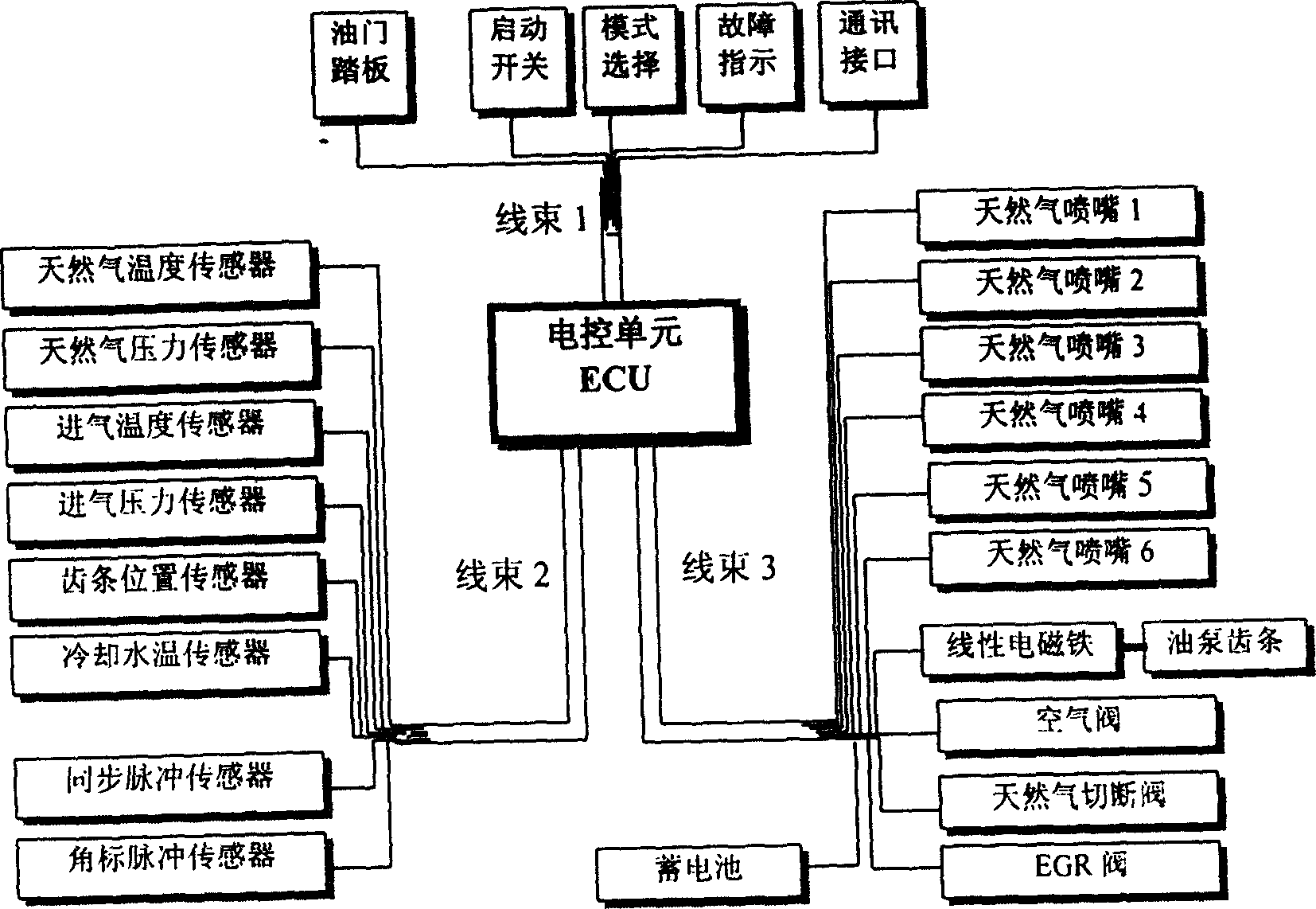

[0030] Such as figure 1 , 2 Shown: a fully electronically controlled diesel / natural gas dual-fuel engine, including engine body 15, cylinder, fuel injection pump 20 and fuel injector 16, is characterized in that: the gas port sequential injection of natural gas is installed at the air intake of each cylinder of the engine device, a proportional electromagnet 22 is installed on the fuel injection pump, and an electronic control system 2 is added; the sequential injection device of the natural gas port is composed of an injection solenoid valve 14 installed at the air inlet of each cylinder and a solenoid valve seat for installing the solenoid valve 13, the electromagnetic valve seat 13 is connected with the natural gas intake valve 30 through the natural gas distribution pipe 29; the natural gas route is composed of a high-pressure gas cylinder 27, a natural gas filter 25, and a natural gas pressure reducing valve 24; a high-pressure gas cylinder, a natural gas filter The natu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com