Carrier bifunction catalyst and its preparation method and application

A dual-functional catalyst, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of unstable ethylene oligomerization catalyst, catalyst α-olefin Problems such as poor selectivity, to achieve the effect of good product shape, low crystallinity and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1. All operations are carried out under anhydrous and oxygen-free conditions, and the solvents used need to be dehydrated and deoxidized.

[0024] 2. SiO 2 Supported bifunctional catalyst system

[0025] (1) SiO 2 Preparation of Supported Bifunctional Catalyst

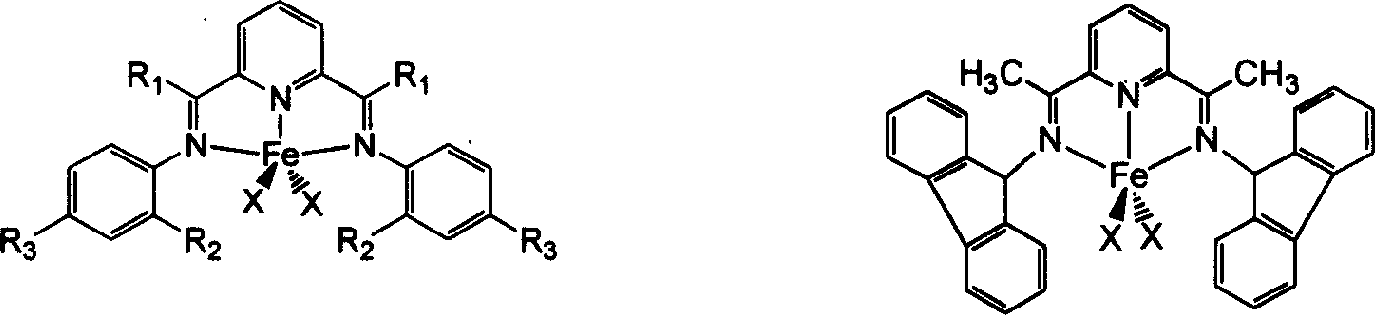

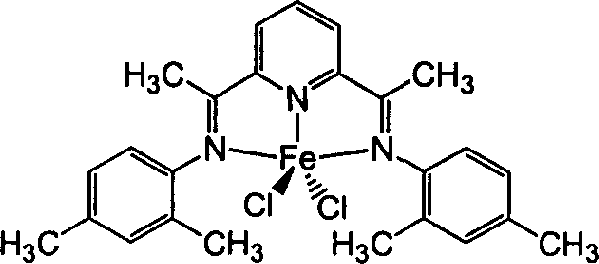

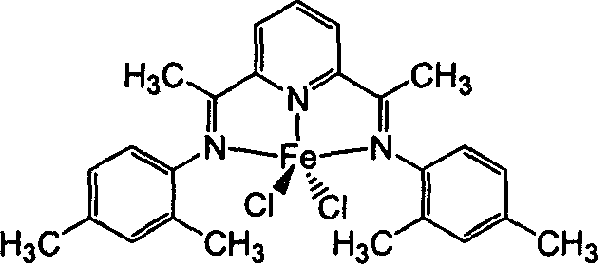

[0026] A: Oligomerization catalyst

[0027]

[0028] B: Copolymerization catalyst Et(Ind) 2 ZrCl 2

[0029] 1gSiO 2 Baking at 400°C for 6 hours, followed by vacuum treatment at 200°C for 2 hours. Cool to 30°C, add 10mL MAO (1.4mol / L toluene solution) and 10mL toluene, and react at 50°C for 12 hours. Wash with toluene, vacuum dry, and store under inert gas for future use. will be 80×10 -6 mol oligomerization catalyst A and 99×10 -6mol copolymerization catalyst B was added to the above system, and then 50 mL of toluene was added, and stirred at 60° C. for 12 hours. Wash with toluene until the supernatant becomes colorless, then vacuum-dry to obtain a supported bifunctional catalyst, which is stored ...

Embodiment 2

[0033] 1. All operations are carried out under anhydrous and oxygen-free conditions, and the solvents used need to be dehydrated and deoxidized.

[0034] 2. Montmorillonite supported bifunctional catalyst system

[0035] (1) Preparation of montmorillonite-supported bifunctional catalyst

[0036] A: Oligomerization catalyst

[0037]

[0038] B: Copolymerization catalyst Et(Ind) 2 ZrCl 2

[0039] 1 g of montmorillonite was calcined at 300°C for 6 hours, and then treated under vacuum at 150°C for 2 hours. After cooling to 30°C, 20 mL of toluene was added to react at 50°C for 12 hours, washed with toluene several times, and then treated under vacuum at 200°C for 2 hours. Cool to 30°C, add 10mL MAO (1.4mol / L toluene solution) and 10mL toluene, and react at 50°C for 12 hours. Wash with toluene, vacuum dry, and store under inert gas for future use. will be 80×10 -6 mol oligomerization catalyst A and 105×10 -6 mol copolymerization catalyst B was added to the above system, ...

Embodiment 3

[0043] 1. All operations are carried out under anhydrous and oxygen-free conditions, and the solvents used need to be dehydrated and deoxidized.

[0044] 2. SiO 2 Supported bifunctional catalyst system

[0045] (1) SiO 2 Preparation of Supported Bifunctional Catalyst

[0046] A: Oligomerization catalyst

[0047]

[0048] B: Copolymerization catalyst Et(Ind) 2 ZrCl 2

[0049] 1gSiO 2 Baking at 400°C for 6 hours, followed by vacuum treatment at 200°C for 2 hours. Cool to 30°C, add 10mL of MAO (1.4mol / L toluene solution) and 10mL of toluene, and react at 70°C for 12 hours. Wash with toluene, vacuum dry, and store under inert gas for future use. will be 80×10 -6 mol oligomerization catalyst A and 102×10 -6 mol copolymerization catalyst B was added to the above system, and then 20 mL of toluene was added, and stirred at 60° C. for 12 hours. Wash with toluene until the supernatant becomes colorless, then vacuum-dry to obtain a supported bifunctional catalyst, which is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com