Process for coking full fraction oil hydrogenation refining

A technology of coking whole distillate oil and hydrofining, which is applied in the field of coking whole distillate oil hydrofinishing to directly obtain second-class diesel standard diesel oil. It can solve the problems of unsuitable treatment properties of coking whole distillate oil, etc., and increase the flexibility of device operation. performance, reduced operating costs, and improved diesel properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0024] The raw materials used are shown in Table 1

[0025] Table 1 Properties of coking whole distillate oil

[0026] Oil product name Raw oil

[0027] Density (20℃), g / cm 3 0.8562

[0028] Distillation range, ℃

[0029] Initial Distillation / 10% 123 / 185

[0030] 30% / 50% 259 / 321

[0031] 70% / 90% 381 / 452

[0032] 95% / final distillation 471 / -

[0033] Alkaline nitrogen, μg / g 1230

[0034] Nitrogen, μg / g 2904

[0035] Sulfur, μg / g 10500

[0036] Freezing point, ℃ 17

[0037] Viscosity (40℃), mm 2 / s 6.725

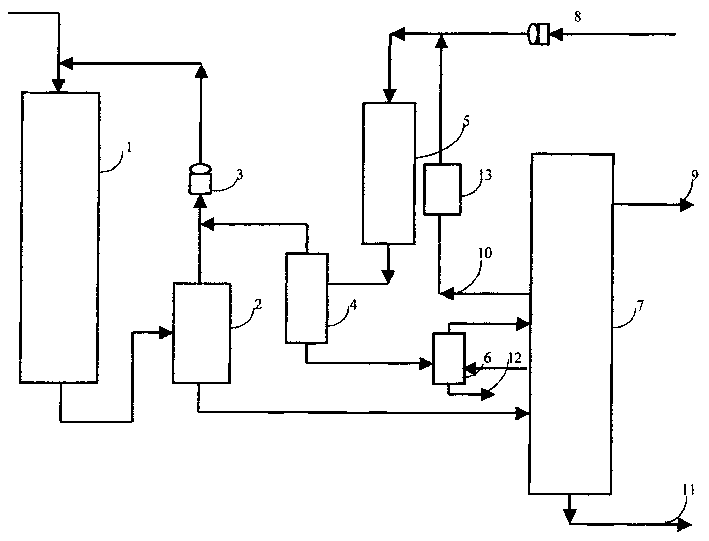

[0038] For specific operation procedures, see the appendix figure 1 . The filling scheme of the coking full distillate hydrofining reactor is to install protective agent on the upper part, the content of molybdenum oxide is 7.0%, the content of nickel oxide is 1.5%, the pore volume is 0.55ml / g, and the specific surface is 180m 2 / g, the pore distribution (10-18nm) was 68%. The loading amount is 10% of the total catalyst volume loading amount. A disti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com