Sewage treatment bioreactor

A technology for bioreactor and sewage treatment, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc. Concentration reduction, treatment system can not work normally, etc., to save energy, reduce solid load, reduce the effect of hydraulic load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The embodiments of the present invention will be further described below in conjunction with the above-mentioned drawings.

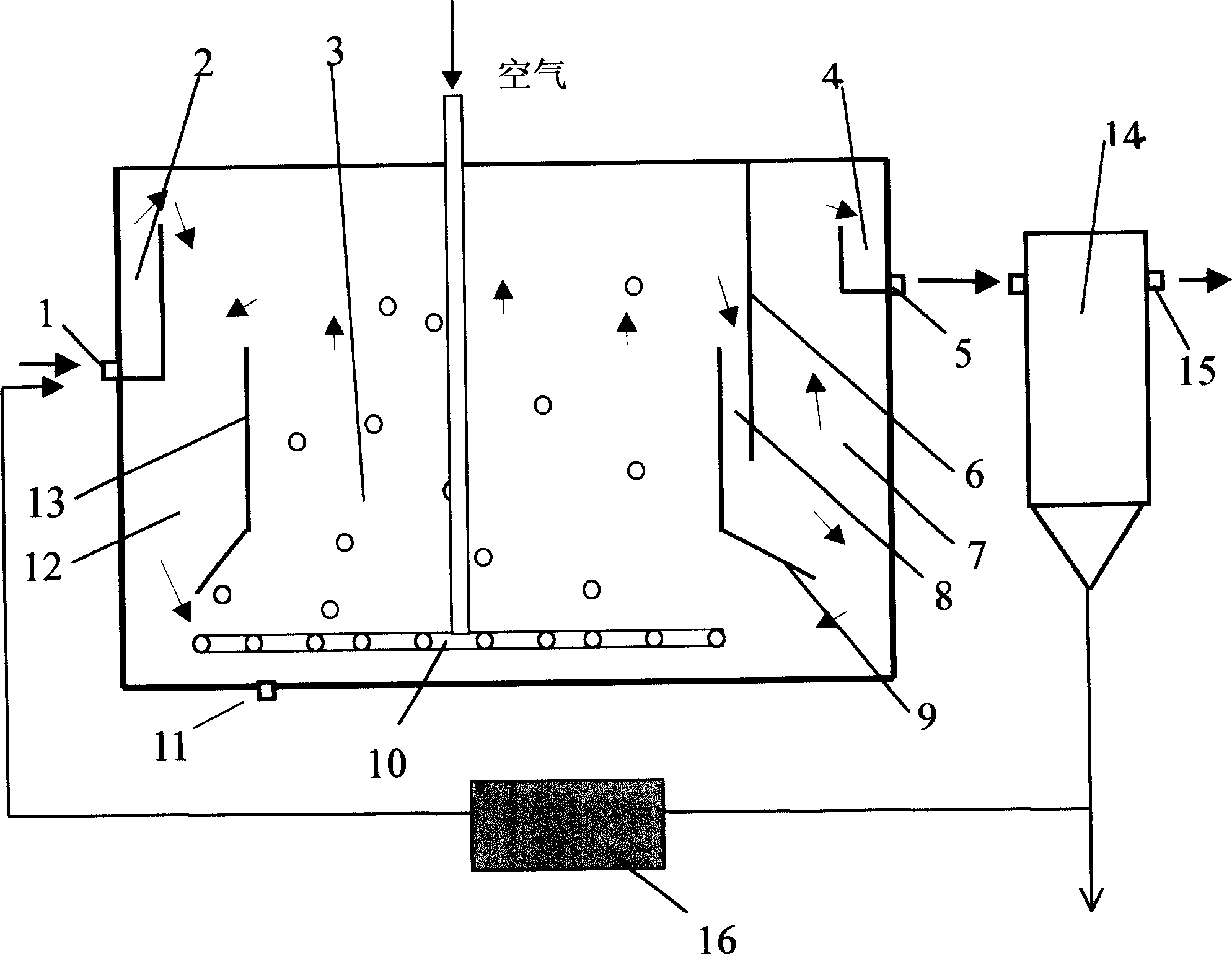

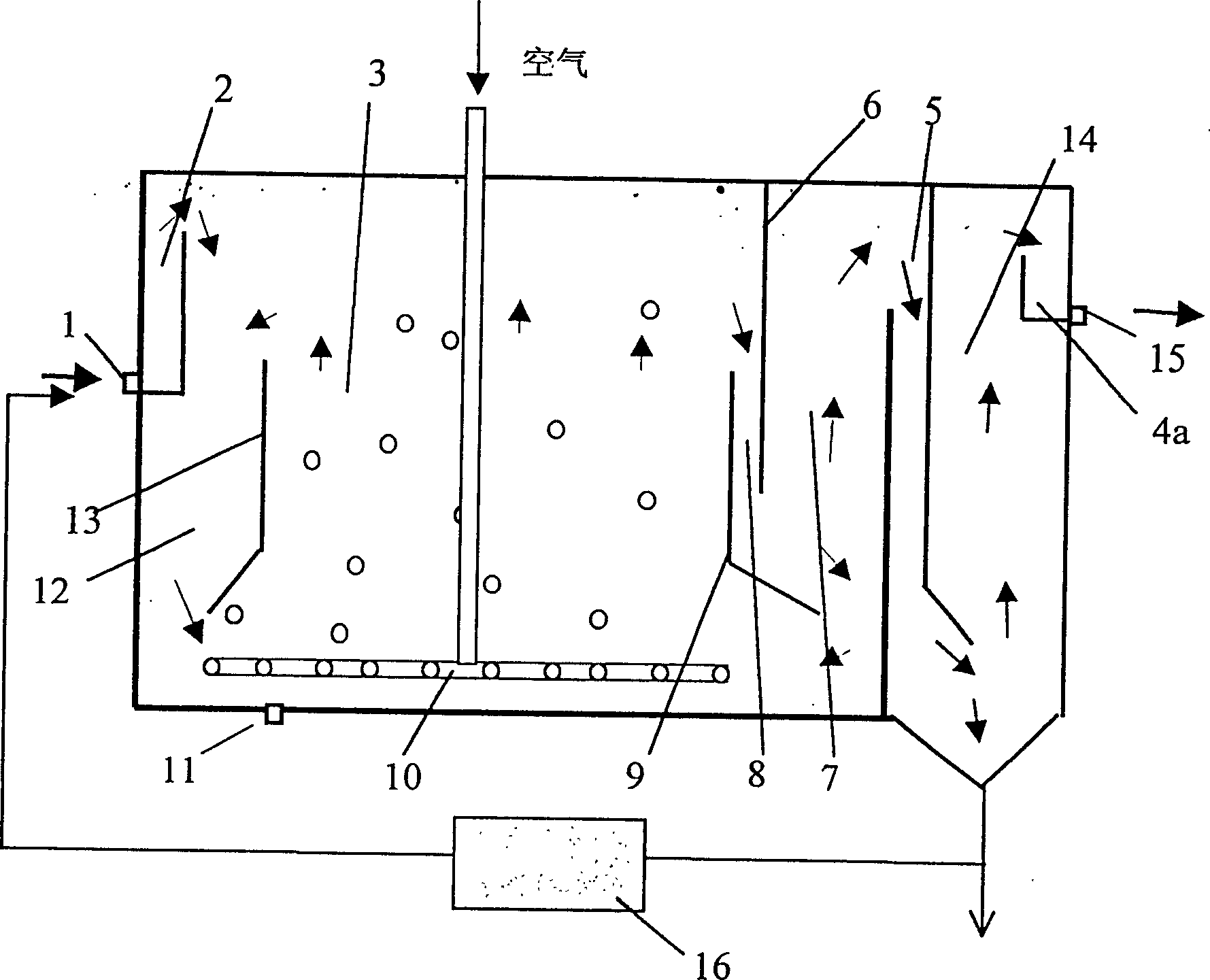

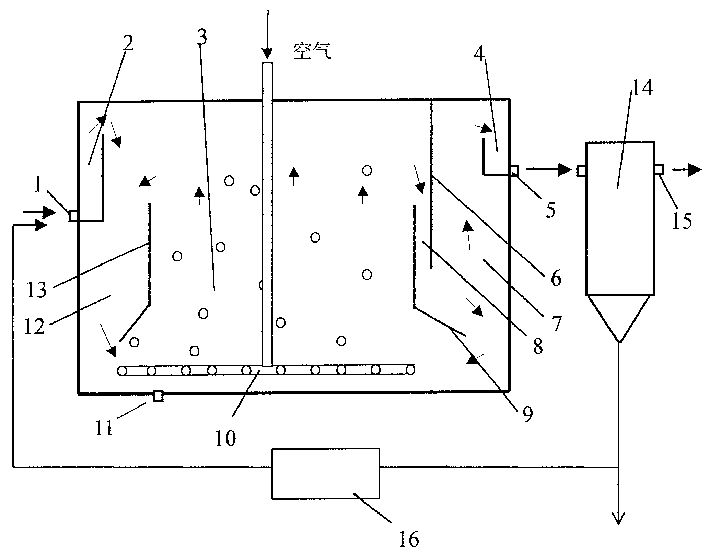

[0024] Figure 1, the bioreactor of the present invention contains a deflector 6 and a deflector 9, which divide the reactor into a mixing zone 3, a static zone 7, and a mixed liquid circulation channel 8. The mixing zone 3 is located between the deflector 9 and the reactor water distribution system 2, the static zone 7 is located between the deflector 6 and the reactor water collection system 4, and the circulation channel 8 for the mixed liquid circulation is located between the deflector 6 and the flow guide between plates 9. An aeration mixing device 10 is provided in the mixing zone 3 . The sewage and the returned activated sludge from the sedimentation tank first enter the mixing zone 3 of the bioreactor through the water inlet 1 and the water distribution system 2 . The sewage and activated sludge are fully mixed and reacted under the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com