Sewing machine

A technology for sewing machines and sewing needles, which is applied in the direction of sewing machine components, needle holders for sewing machines, sewing equipment, etc., and can solve problems such as difficulties and complicated replacement operations of needle clamp parts 3

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

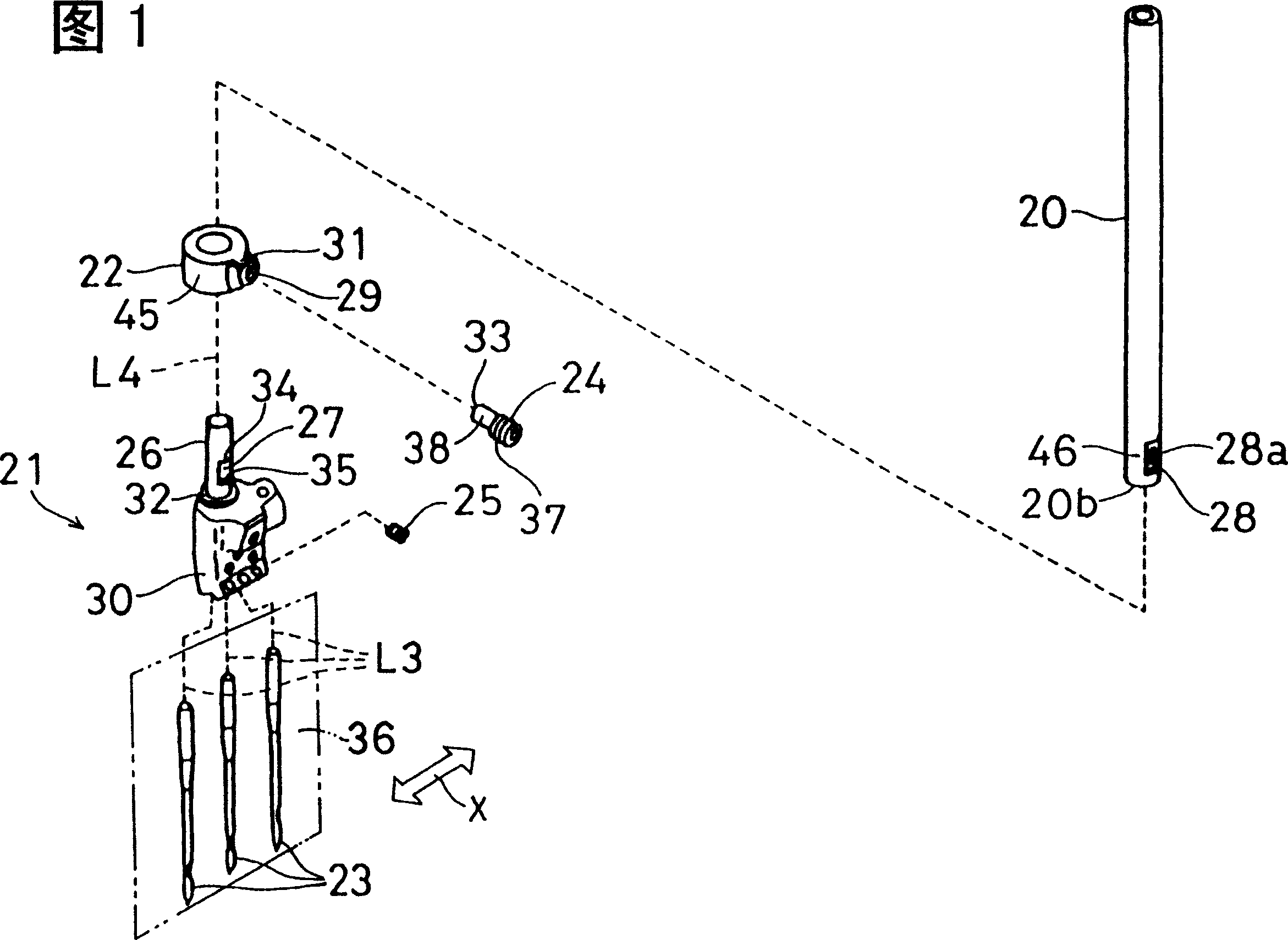

[0044] Refer to Figure 1 to Figure 5 A first embodiment of the present invention will be described. And in the sewing machine of the present invention, the structures other than the connecting portion of the needle bar and the needle clamp member are different from those in the Figure 12 It is the same as the past flat chain sewing machine 1 explained in Fig. 15, and Figure 12 The drawing descriptions related to each drawing of FIG. 15 are used in the first embodiment here.

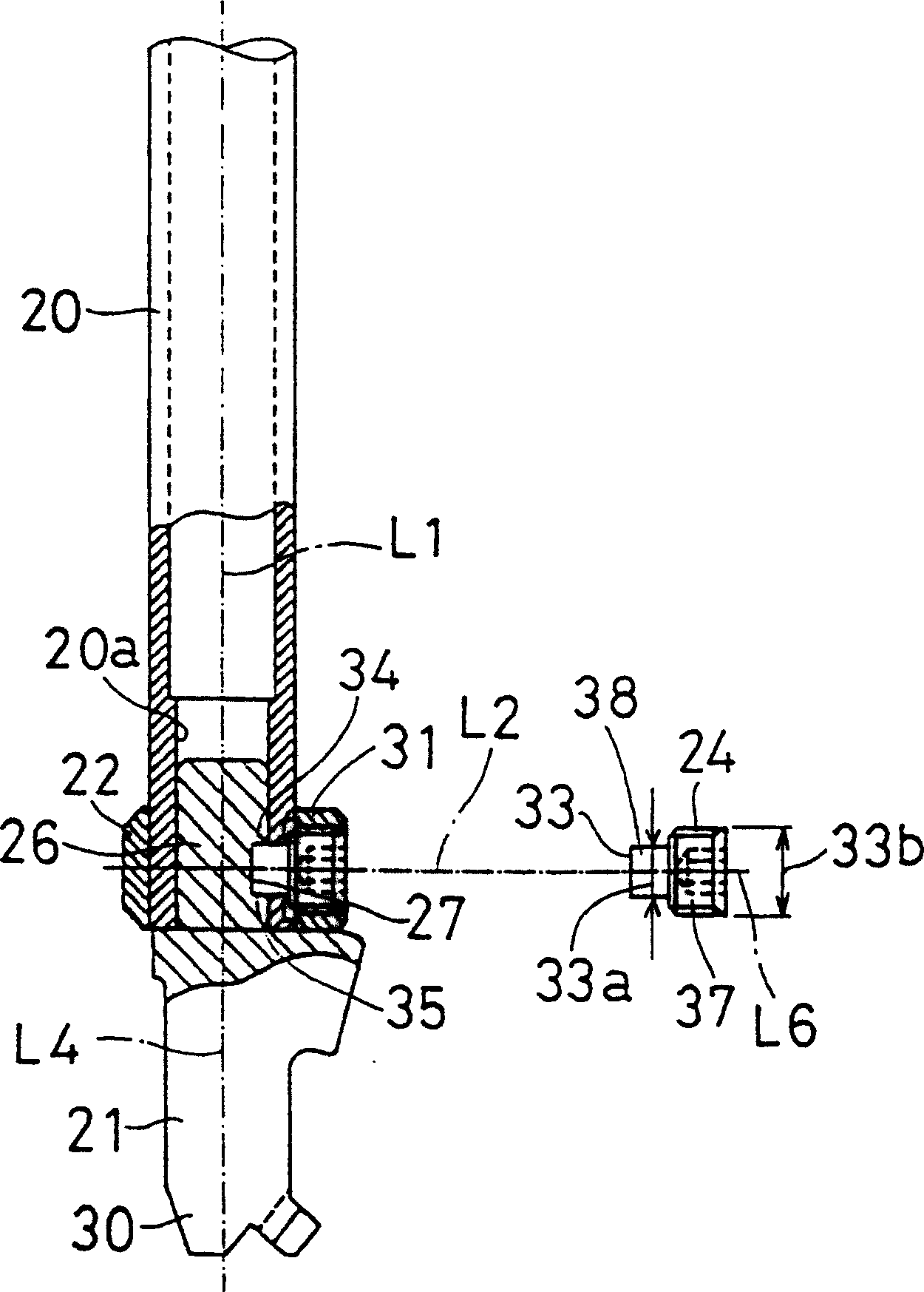

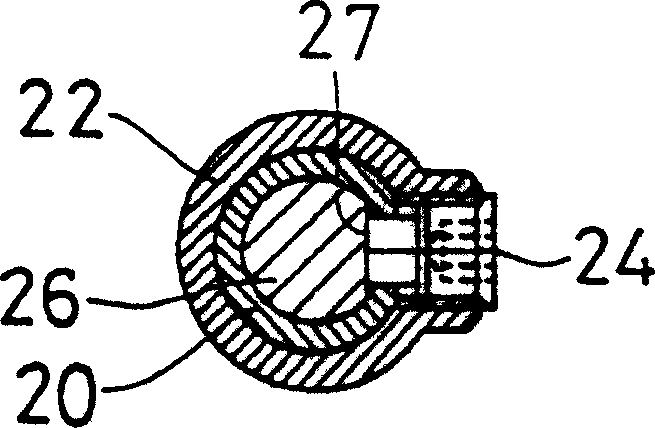

[0045] Fig. 1 shows the exploded perspective view of the needle bar 20 and the needle clip part 21 of the present embodiment, figure 2 A longitudinal sectional view showing the connecting portion of the needle bar 20 and the needle clamp member 21, image 3 Representing the cross-sectional view of the connecting portion of the needle bar 20 and the needle clamp member 21 at right angles to the axis, Figure 4 express figure 2 An enlarged cross-sectional view of a part of Figure 5 Indicated by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com