Spliting method for DL-pantoyl intenral ester

A technology of pantothenolactone and resolution agent, which is applied in the field of resolution of DL-pantothene lactone, can solve the problems of low resolution yield, low resolution yield and large dosage of L-calcium pantothenate, and achieve The effect of improving the total utilization rate, reducing production costs, and high split yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

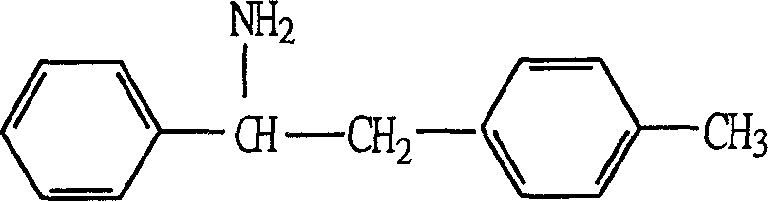

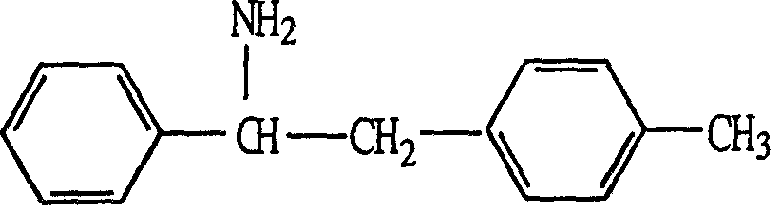

[0018] Embodiment 1 (resolving agent R-NH 2 purification)

[0019] Accurately weigh 285 grams of R-NH 2 The crude product (industrial pure, commercially available) is added in 474 milliliters of anhydrous toluene, 64.8 grams of glacial acetic acid are added in a 250 milliliter constant pressure dropping funnel, slowly added in the toluene, after the dropwise addition, the water bath is heated to 80 -85°C, react for 0.5 hours, transfer to a 200ml large beaker after completion, cool naturally at room temperature, and then use an ice-water bath to cool to 0-10°C for crystallization, crystallization is complete, filter, and the filtrate is used for the next batch. , the solid was directly used for the next step of recrystallization.

[0020] Put the above solid into a 1000 ml three-necked flask, then add 423 ml of toluene, heat up the water bath to dissolve it, and keep it under reflux for 0.5 hours, then transfer it to a 1000 ml flask after completion, repeat the above crystall...

Embodiment 2

[0022] Embodiment 2 (preparation of DL-panthenolactone hydrolyzate)

[0023] Add 70.5 g of DL-panthenolactone into a 1000 ml four-necked flask, measure 210 ml of 2 mol / L sodium hydroxide, pour it into the flask, install a thermometer, put the reflux condenser in the four-necked flask, and under stirring, Raise the temperature to 75-80°C and hydrolyze for 0.5 hours. Finished, measured pH value is 9-10 is advisable. Then adjust the pH value to 7.5-8 with 2 mol / L hydrochloric acid.

Embodiment 3

[0024] Embodiment 3 (resolution of DL-panthenolactone)

[0025] 61.5 g R-NH 2 Add 0.25 ml of concentrated hydrochloric acid to the resolving agent, stir to form a salt, add 480 ml of water, heat to 80-85°C in a water bath to dissolve it, add the DL-pantolactone hydrolyzate in the above example 2, and control the dropping time Not less than 1 hour, the rate of addition is 5 ml / min, stirring at 450 rpm, the temperature of the water bath is 70-75°C, after dropping, continue to stir for 1 hour, cool to room temperature, vacuum filter, and the filter cake is used to recover D - pantothenolactone and most of the resolving agent, the filtrate decompresses and recovers water, making it 1 / 3 of the original volume, after the completion, adjust 10-11 with 2 mol / liter sodium hydroxide, and use 200 ml of toluene, 250 Milliliter extraction twice, the extract toluene is used to recover a small amount of resolving agent R-NH dissolved in the filtrate 2 , the aqueous phase is adjusted to pH ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com