Electric iron with exchangeable rservoir

A technology for electric irons and containers, applied in hand irons, washing devices, textiles and papermaking, etc., can solve the problems of reduced internal pressure and reduced spraying effect, and achieve the effect of reducing the risk of clogging or pollution and eliminating accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

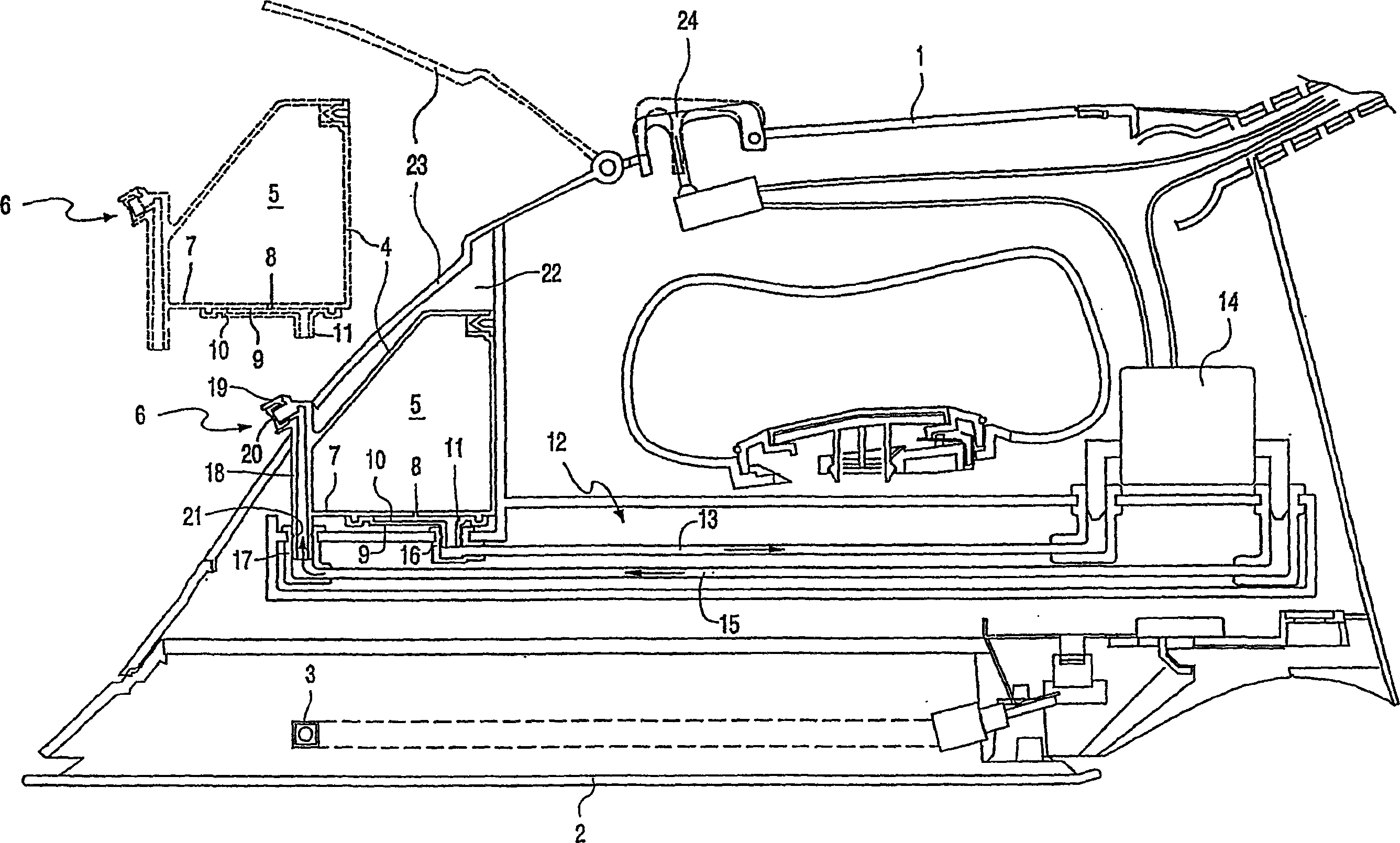

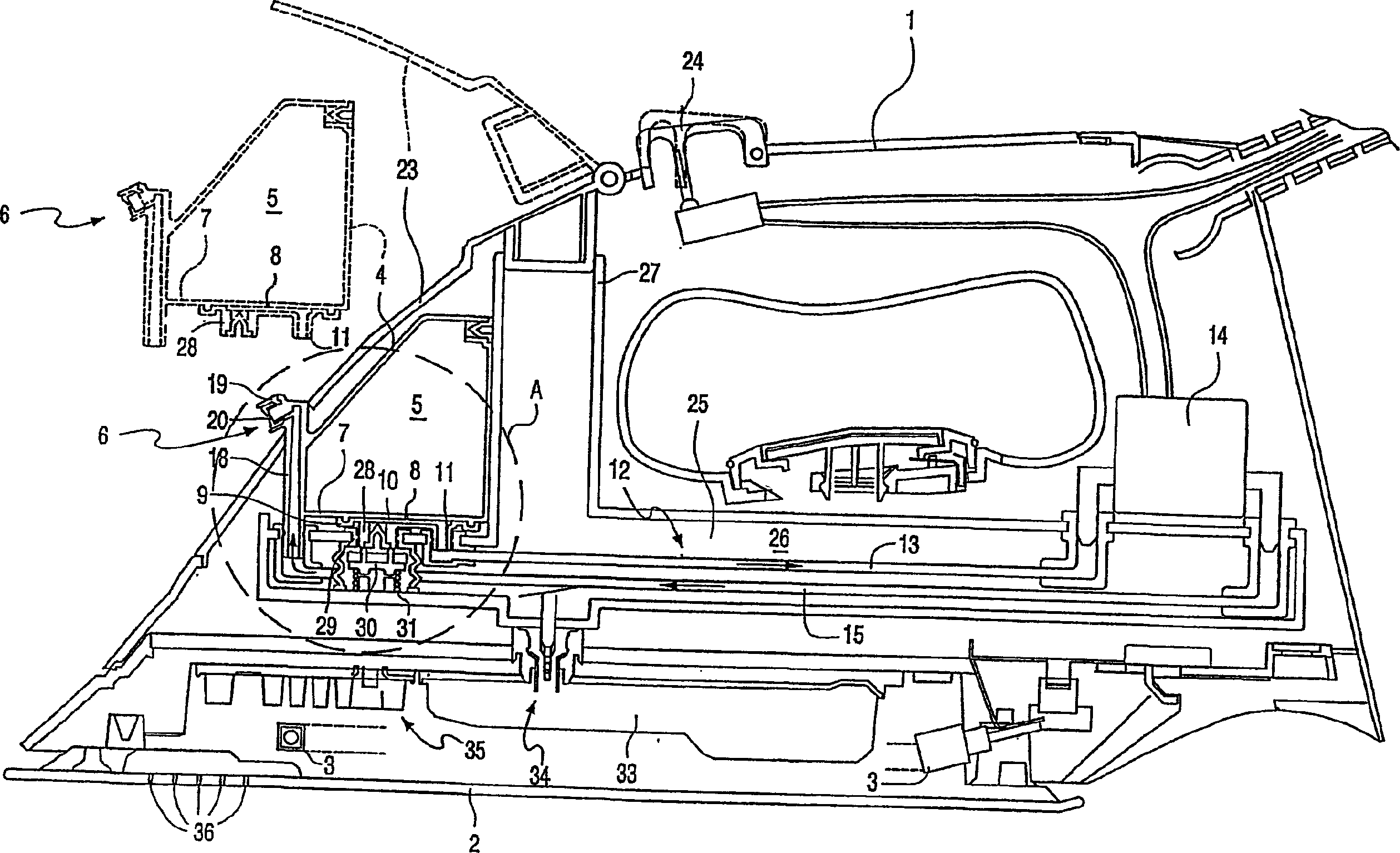

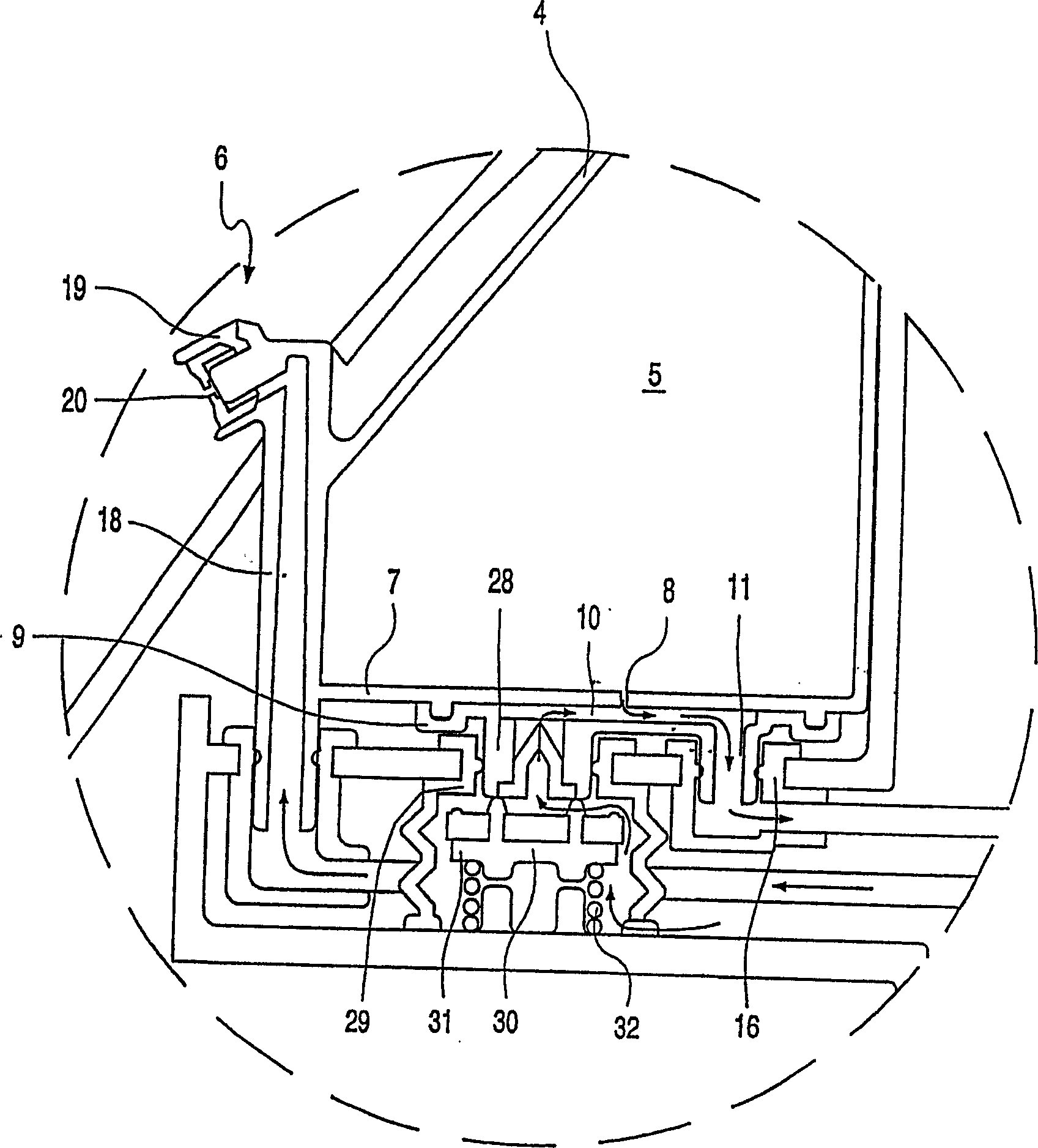

[0015] Such as figure 1 As shown, the iron according to the invention comprises a casing 1 , a soleplate 2 , a heating element 3 for heating the soleplate, a replaceable container 4 for containing a liquid 5 , and a nozzle arrangement 6 . The replaceable container 4 may be a case or box having a hard synthetic resin shell. The liquid 5 in the replaceable container is a so-called additive liquid with a certain particle size and viscosity. The bottom 7 of the replaceable container 4 is provided with an outlet 8 for the liquid 5 . Connected to the bottom surface of the bottom 7 is a connecting piece 9 which has a conduit 10 whose inlet communicates with the outlet 8 of the container 4 and whose outlet is terminated in an outlet pipe 11 . In a first preferred embodiment the connecting piece 9 may be integral with the box. The iron comprises a transfer system 12 for transferring liquid 5 from the replaceable container 4 to nozzle means 6 for spraying the liquid 5 onto the clothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com