Static water pressure loop pressure regulation valve with reduced input torsion required by static water pressure element

A pressure regulating valve, hydrostatic pressure technology, applied in the direction of servo meter circuit, fluid pressure actuation device, fluid pressure actuation system components, etc., can solve the problems that the manufacturer cannot guarantee, and achieve the effect of cheap manufacturing and torque reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

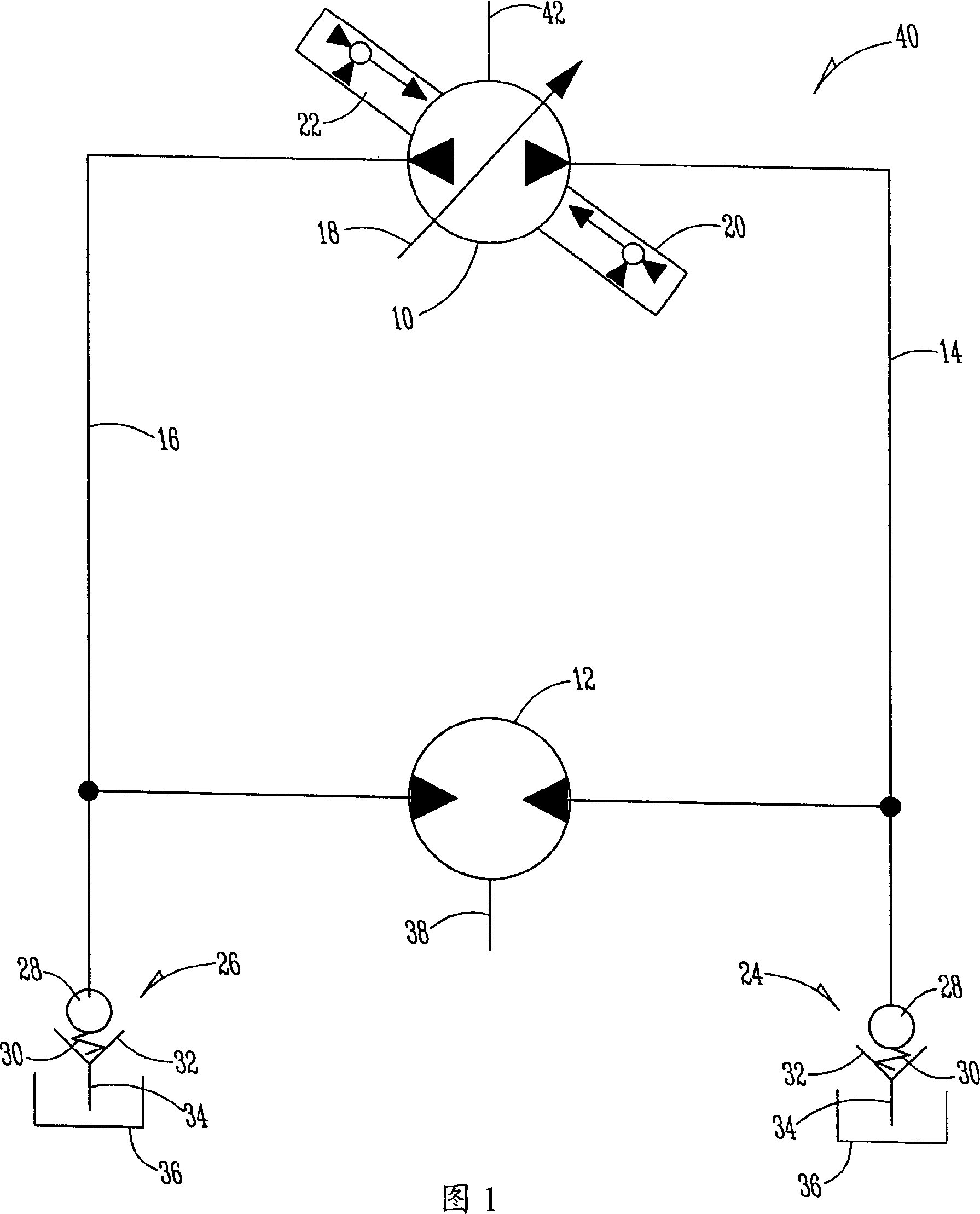

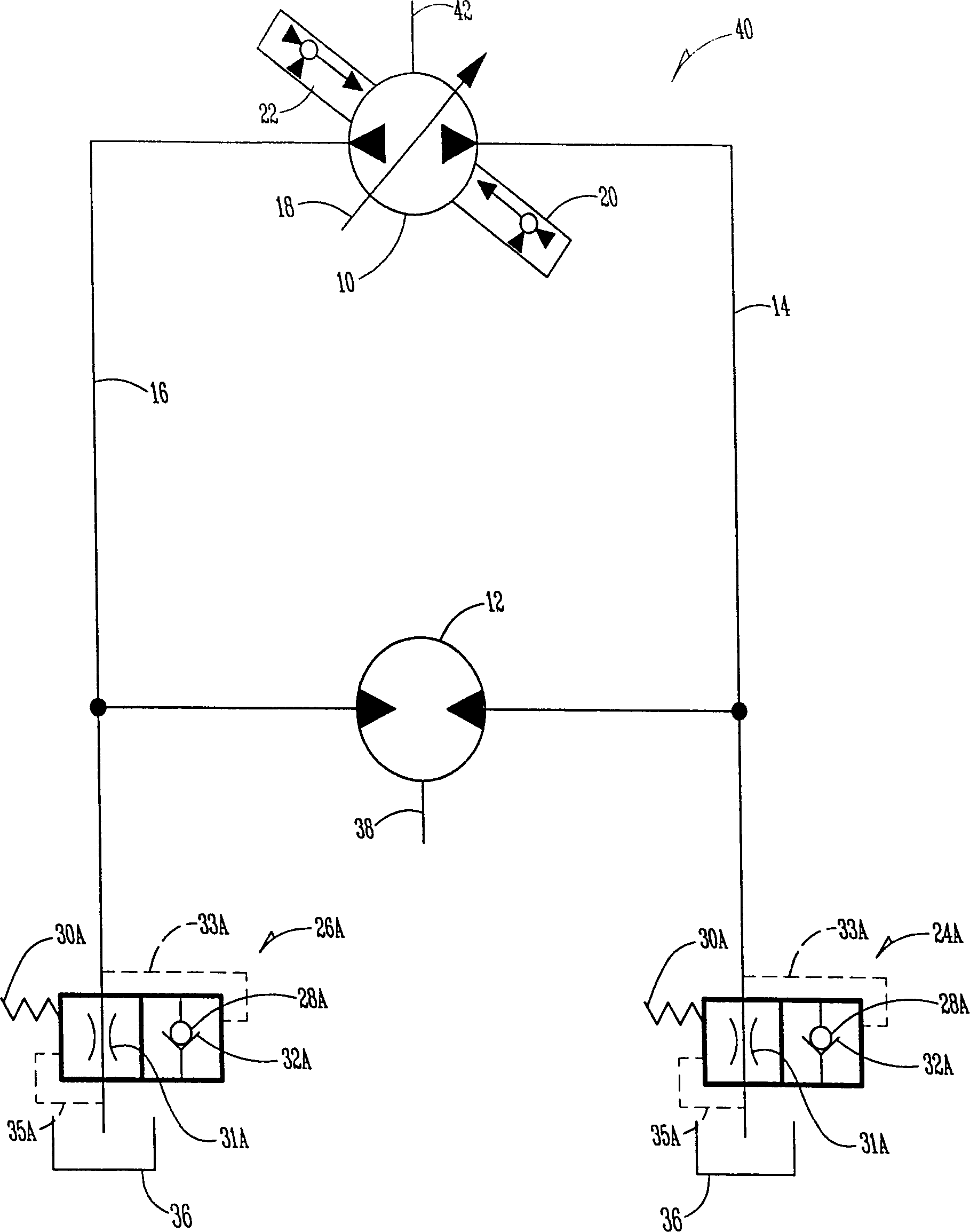

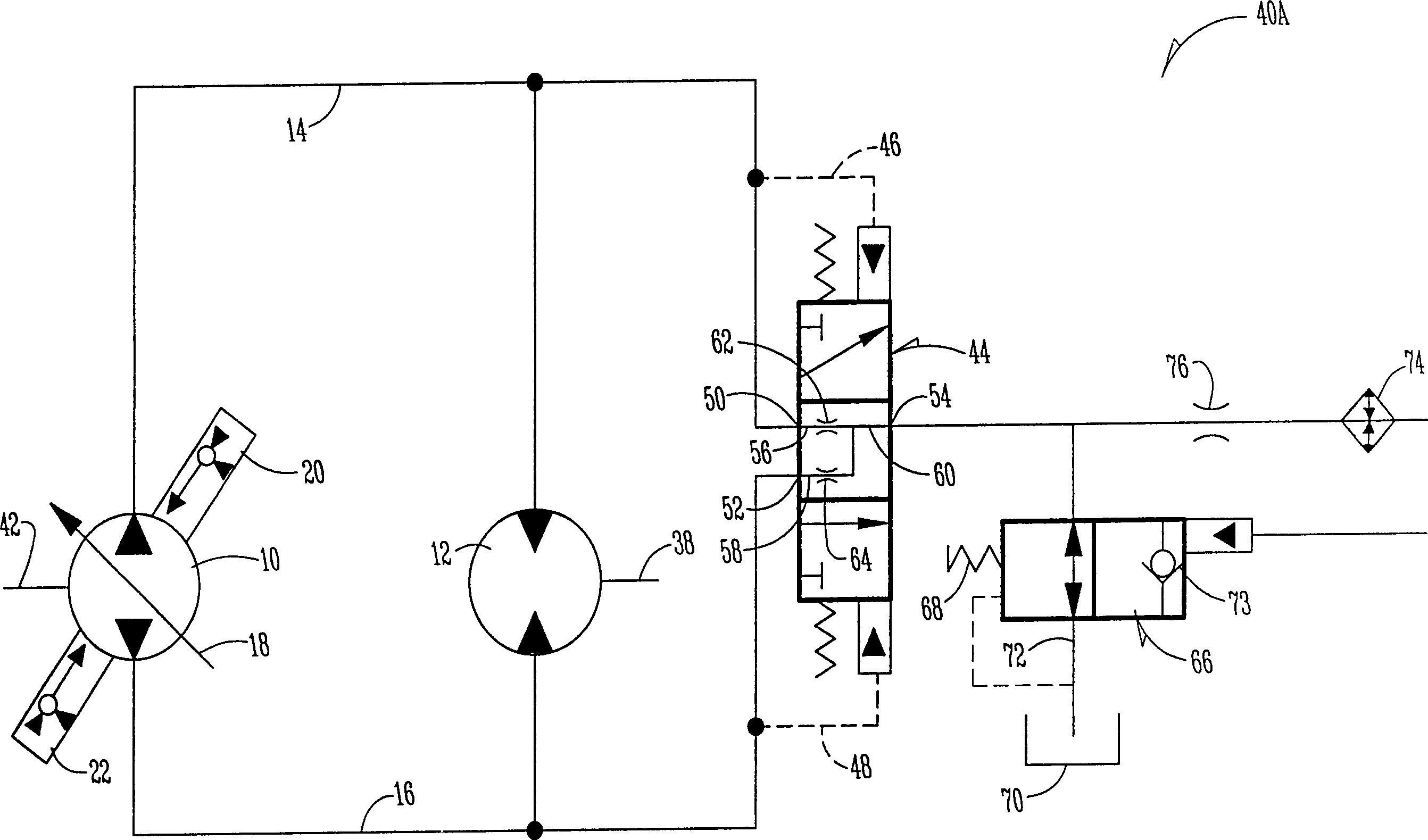

[0016] In the drawings, the same structures are given the same reference numerals. Figure 1 discloses an embodiment of the invention. The variable displacement hydraulic pump 10 is connected in closed circuit to the hydraulic motor 12 by means of a pair of system or working pressure lines 14 , 16 . Preferably, the pump 10 is a variable displacement pump having a fluid volume varying element 18 whose position is controlled by means of opposing servomechanisms 20 , 22 . Hydraulic motor 12 may be a constant displacement motor (as shown) or a variable displacement motor.

[0017] Pressure regulating valves 24 , 26 are connected to first and second system pressure lines 14 , 16 , respectively. Each pressure regulating valve 24, 26 includes a check ball 28 which is biased by a spring 30 to a position in which it cannot engage a seat 32 at the inlet of a line 34 which Connected to the cassette ejector or container 36 . Preferably, the pressure regulating valves 24, 26 are actuall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com