Connecting and positioning joint means for adjusting clothing waistline measurement, and clothings containing same

A technology for combining parts and clothes, which is applied in the direction of sewing tools, clothing belts, hook fasteners, etc., and can solve the problems of excess belt lower part, poor appearance, and insufficient size of the lower part.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

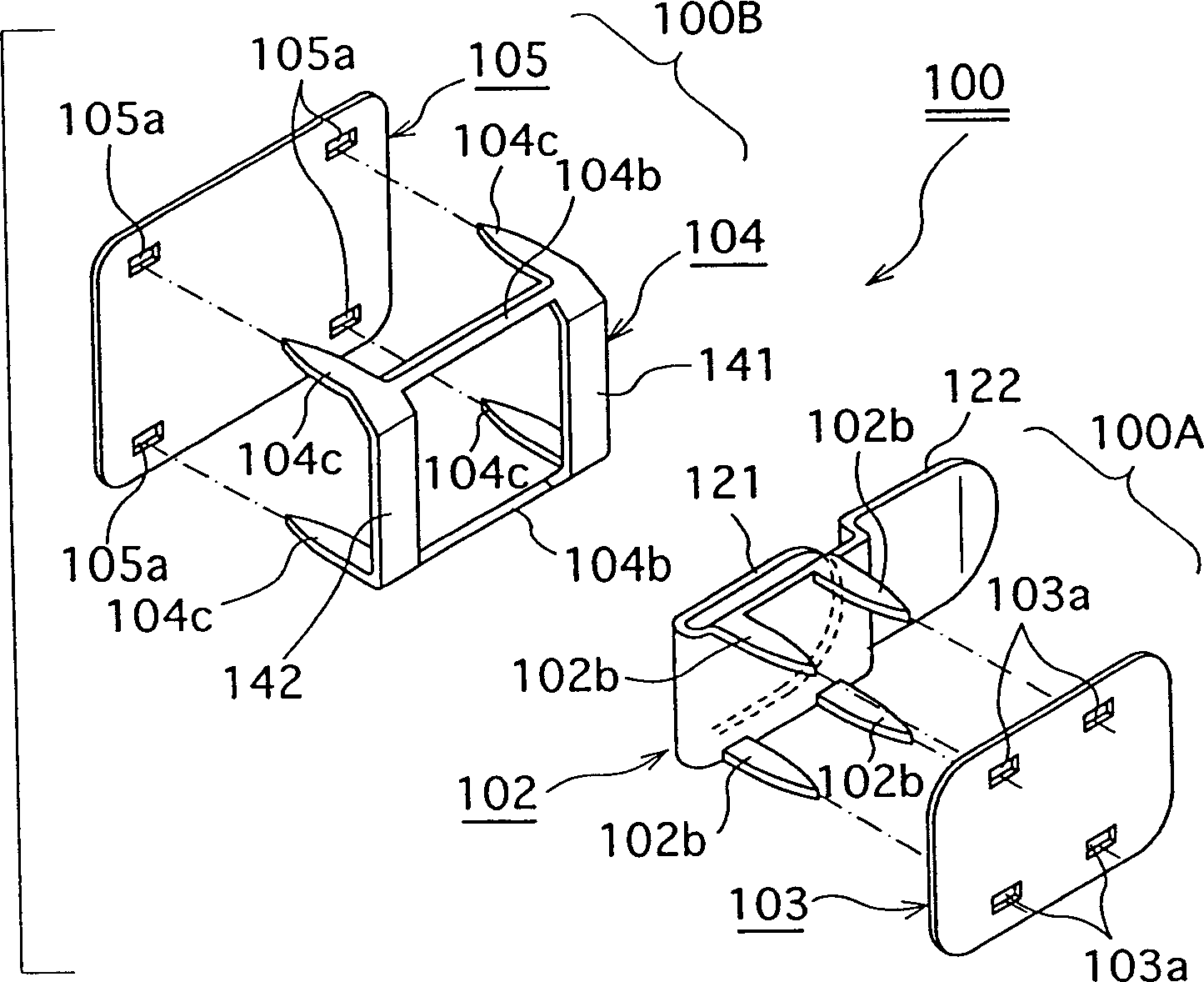

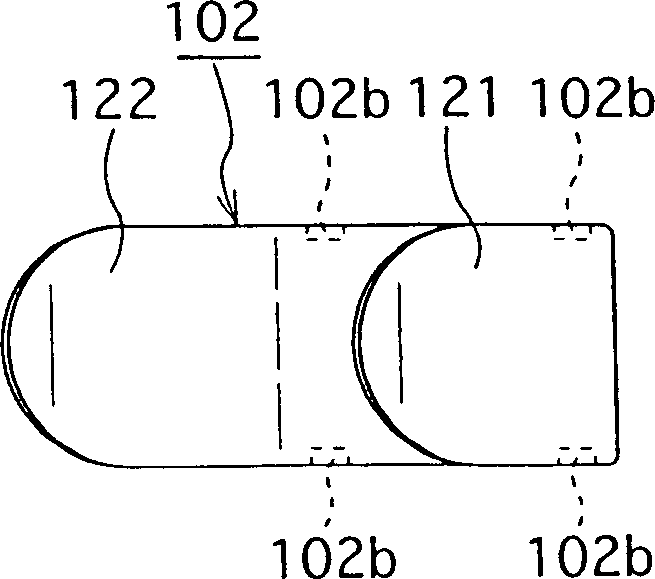

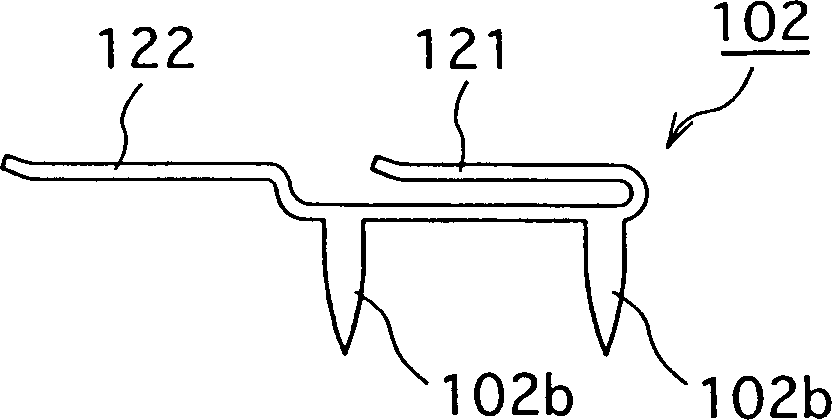

[0137] figure 1 It is an exploded perspective view showing the hook positioning joint of the first embodiment of the present invention. figure 2 It is a front view showing the hook part body of the hook assembly of the hook positioning coupling according to the first embodiment of the present invention. image 3 It is a plan view showing the hook body of the hook assembly of the hook and positioning coupling according to the first embodiment of the present invention. Figure 4It is a front view showing the hook part mounting plate of the hook assembly of the hook positioning coupling according to the first embodiment of the present invention. Figure 5 It is a plan view of the hook part mounting plate of the hook assembly of the hook positioning coupling according to the first embodiment of the present invention. Figure 6 It is an exploded perspective view showing the hook body of the hook assembly of the hook positioning coupling according to the first embodiment of the ...

Embodiment 2

[0169] Next, a second embodiment will be described.

[0170] Figure 15 It is an exploded perspective view showing the hook positioning joint of the second embodiment of the present invention. The hook positioning joint 100 of the second embodiment is in the hook positioning joint 100 of the first embodiment, the hook portion is formed on the joint part with the hook body 102 of the hook mounting plate 103X of the hook assembly 100AX The concave-convex curved portion 103b into which the claw 102b enters, and the concave-convex curved portion 105b into which the claw 104c of the receiving part enters is formed on the joint portion with the receiving body 104 of the receiving mounting plate 105X of the receiving assembly 100BX. In addition, the hook attachment plate 103X has a through-hole 103ax corresponding to the through-hole 103a. Furthermore, the receiving mounting plate 105X has a through-hole 105ax corresponding to the through-hole 105a.

[0171] Further, a concave-con...

Embodiment 3

[0175] The third embodiment will be described below.

[0176] Figure 16 It is an exploded perspective view showing the receiving assembly 100BY of the hitch positioning joint 100 according to the third embodiment of the present invention.

[0177] In the receiving unit 100BY of the third embodiment, the joint portion of the receiving part mounting plate 105Y and the receiving body 104 is formed with a concave-convex curved part 105by into which the receiving part claws 104c enter.

[0178] Moreover, on the joint portion of the receiving part mounting plate 105Y of the receiving assembly 100BY and the receiving body 104, in order to obtain a margin for the connection part 104b of the receiving body 104 to enter, only the concave-convex curved part 105by is used as the area where the receiving part claw 104c enters. . In addition, the receiving mounting plate 105Y has 105ay corresponding to the through-hole 105a.

[0179] Furthermore, one concave-convex portion 105c composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com