Infant onesie card board production method

A production method and jumpsuit technology, which is applied in the field of paper plate production for baby jumpsuits, can solve the problems of time-consuming and labor-consuming, difficulty in ensuring the wearing comfort of infants, and affecting the production efficiency of enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

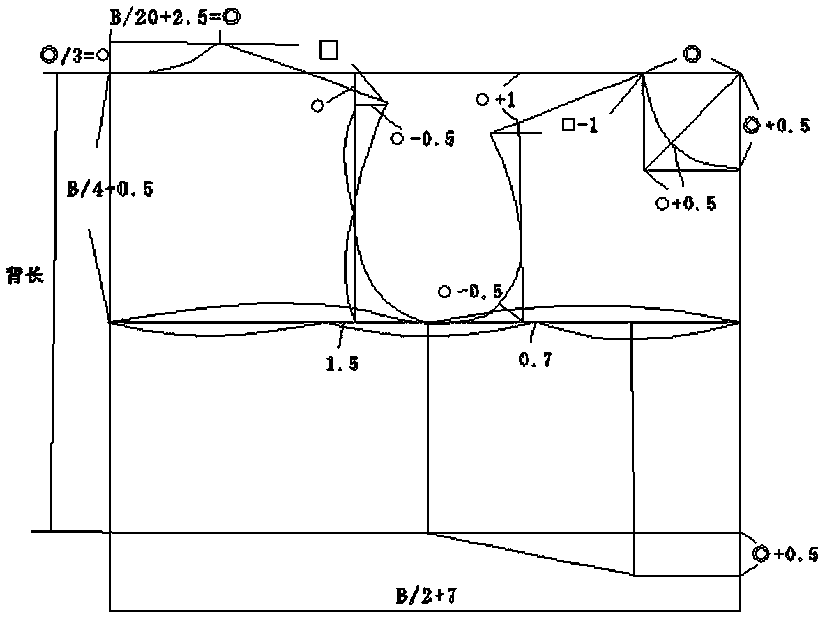

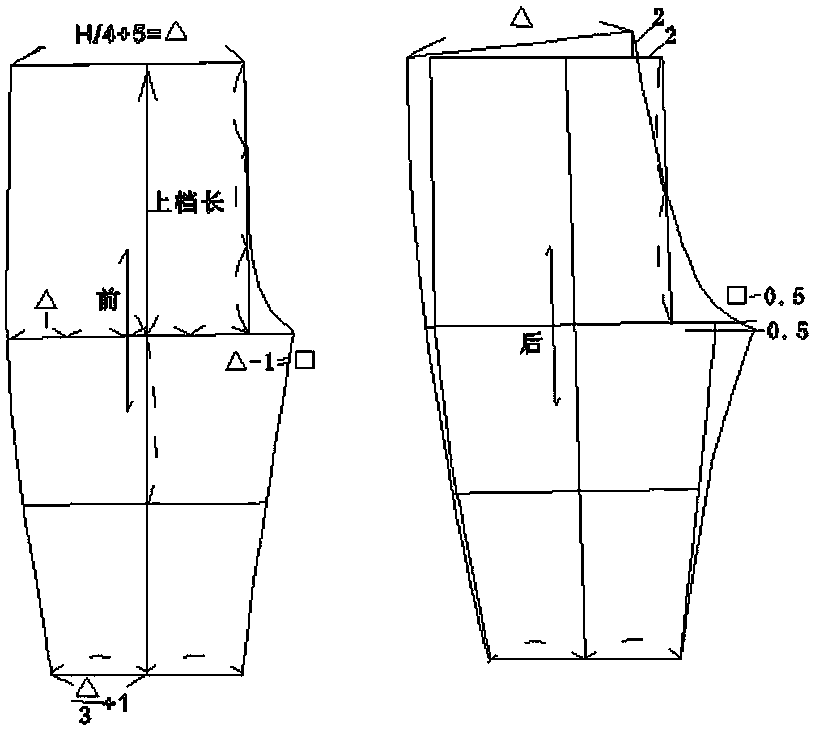

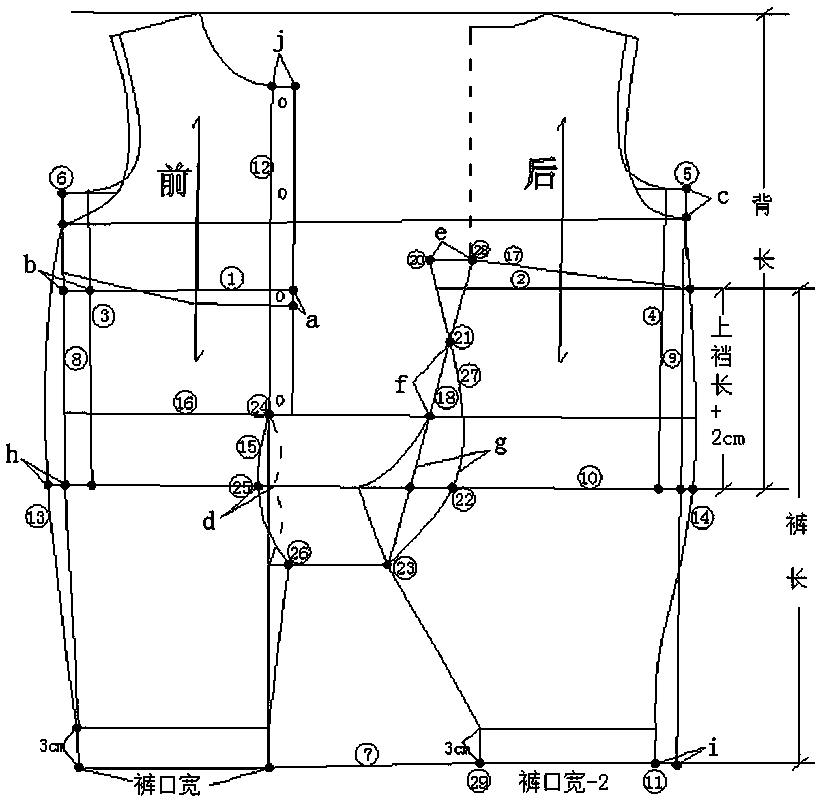

[0047] combine image 3 , the present embodiment provides a method for making a paper version of a baby jumpsuit. The structure is made by using the prototype of the Japanese culture-style children's clothing jacket and the prototype of the children's clothing trousers. It is mainly suitable for wearing by thin babies, and specifically includes the following step,

[0048] Step 1.1: Fabricate the structure of the upper body, including,

[0049] Make front waistline The position is higher than the waist line of the back piece Reduce the size a to 1cm; add a bust relaxation amount of 2cm to the side seam ③ of the front piece and the side seam ④ of the back piece. In this step, the waistline of the front piece is lowered by 1cm on the basis of the prototype of Japanese cultural children's clothing The position, the structure with 2cm more bust relaxation at the front and rear side seams ensures the relaxation of the baby's physical activities and improves the baby's wearing ...

Embodiment 2

[0064] combine image 3 , the present embodiment provides a method for making a paper version of a baby jumpsuit. The structure is made using the prototype of the Japanese culture-style children's clothing coat and the prototype of the children's clothing trousers. It is mainly suitable for wearing by a medium-sized baby, and specifically includes the following step,

[0065] Step 1.1: Fabricate the structure of the upper body, including,

[0066] Make front waist line The position is higher than the waist line of the back piece Reduce the size a to 1cm; add a bust relaxation amount of 2cm to the side seam ③ of the front piece and the side seam ④ of the back piece. In this step, the waistline of the front piece is lowered by 1cm on the basis of the prototype of Japanese cultural children's clothing The position, the structure with 2cm more bust relaxation at the front and rear side seams ensures the relaxation of the baby's physical activities and improves the baby's wear...

Embodiment 3

[0081] combine image 3 , the present embodiment provides a method for making a paper version of a baby jumpsuit, the structure of which is made using the prototype of the Japanese culture-style children's clothing jacket and the prototype of children's clothing trousers, which is mainly suitable for overweight babies, and specifically includes the following step,

[0082] Step 1.1: Fabricate the structure of the upper body, including,

[0083] Make front waistline The position is higher than the waist line of the back piece Reduce the size a to 1cm; add a bust relaxation amount of 2cm to the side seam ③ of the front piece and the side seam ④ of the back piece. In this step, the waistline of the front piece is lowered by 1cm on the basis of the prototype of Japanese cultural children's clothing The position, the structure with 2cm more bust relaxation at the front and rear side seams ensures the relaxation of the baby's physical activities and improves the baby's wearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com