External-compression rotary piston engine

A technology of rotary piston and engine, applied in the direction of rotary piston engine, rotary or oscillating piston engine, internal combustion piston engine, etc., can solve the problems of easy formation of flutter ripples, poor fuel economy, affecting the service life of the rotor engine, etc. Achieving the effect of convenient series modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

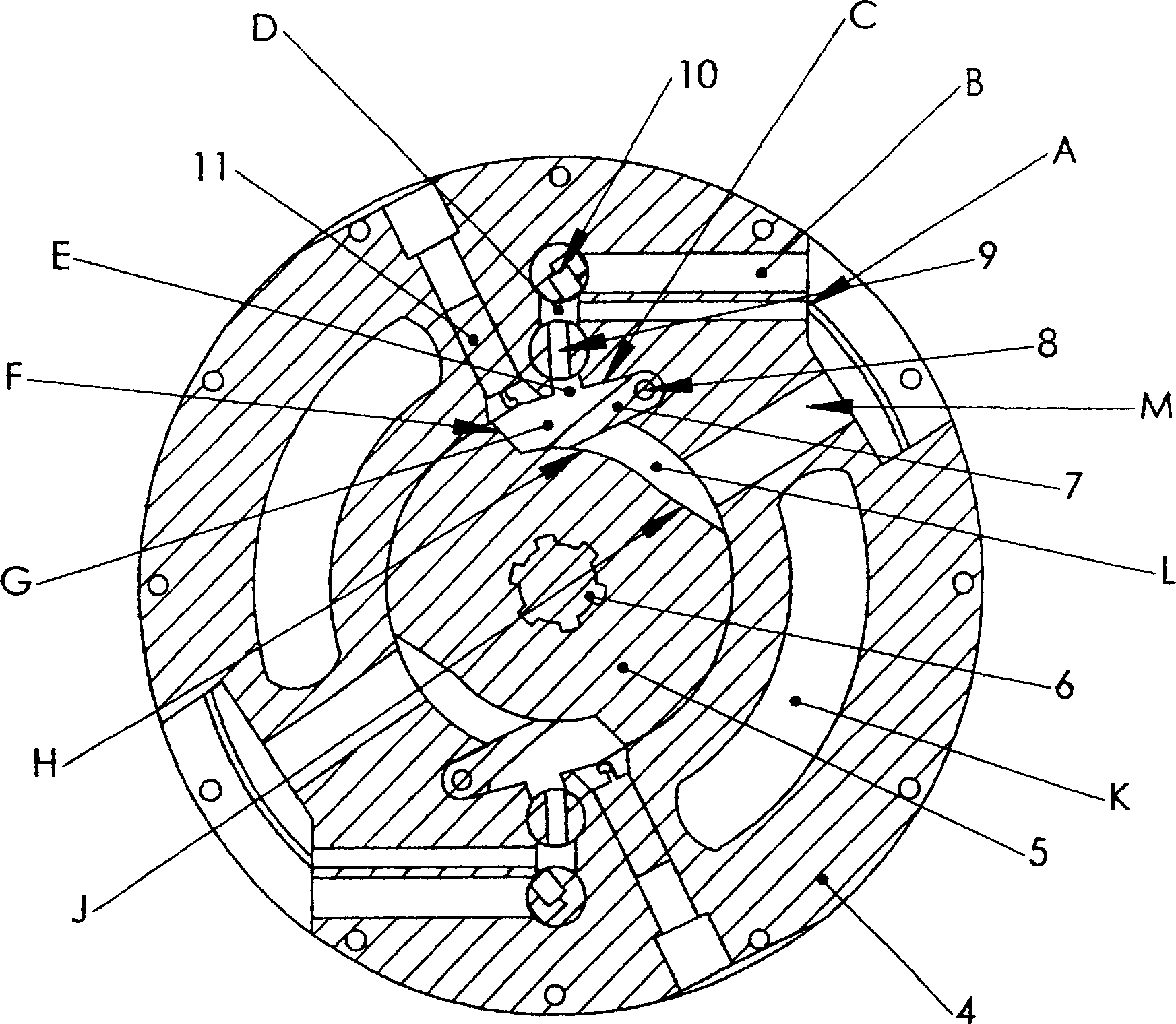

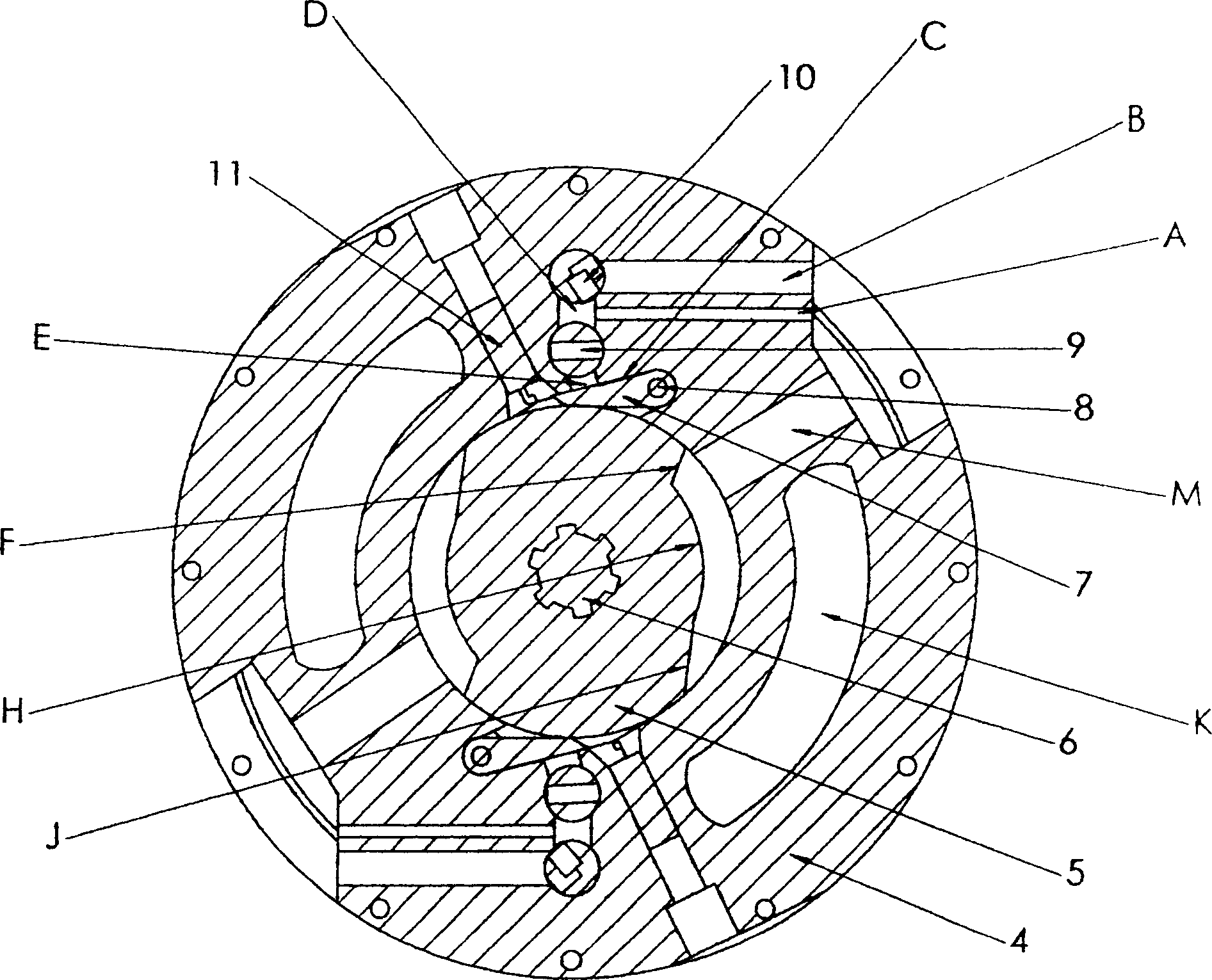

[0028] Below, the present invention will be described in detail in conjunction with the accompanying drawings by taking the externally compressed gas type rotary piston gasoline engine with two combustion chambers as an example.

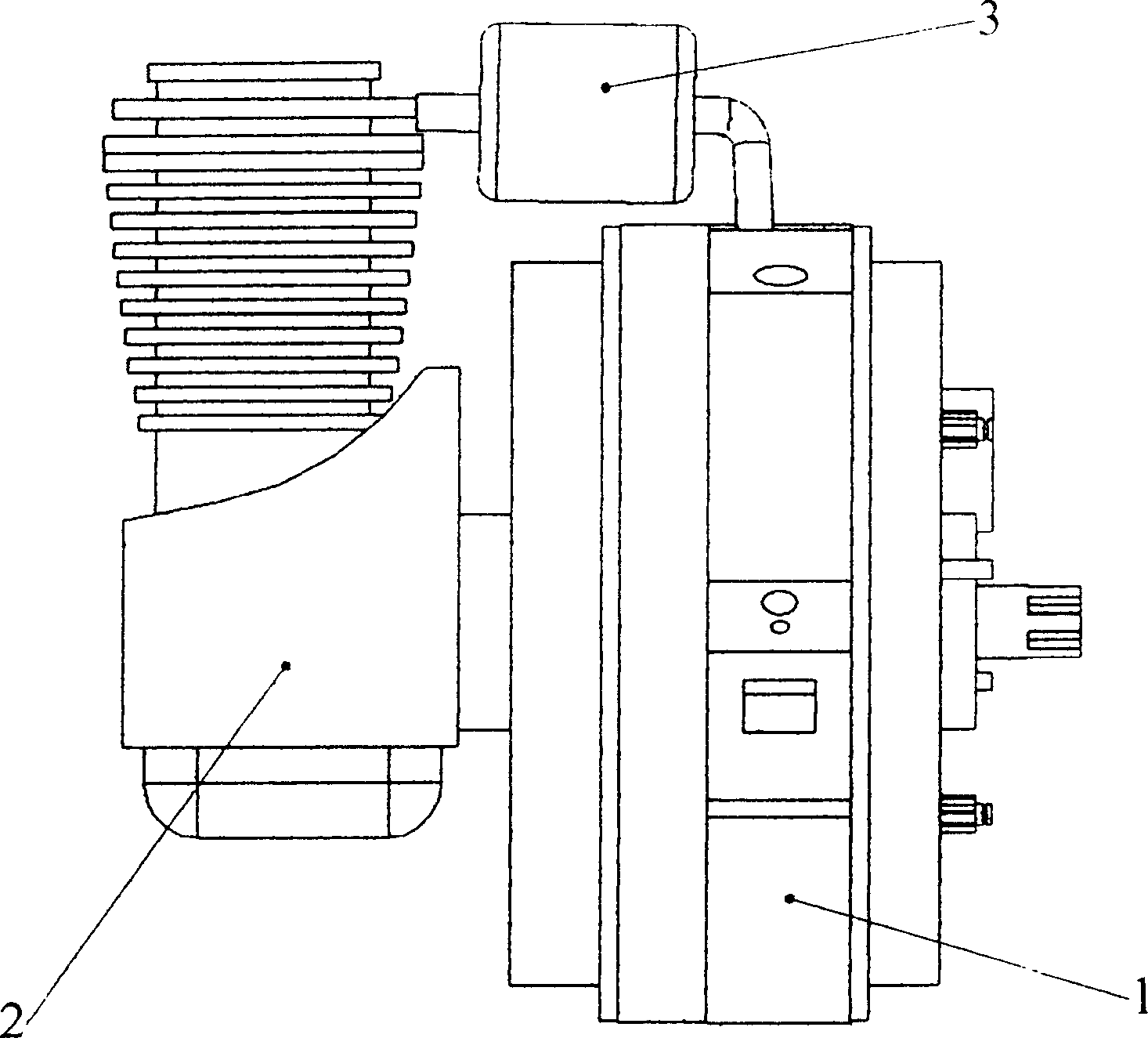

[0029] Such as figure 1 As shown, the external pressure air type rotary piston engine of the present invention is mainly composed of three major parts: a coaxial rotor machine 1, an air compressor 2 and a pressure regulator 3.

[0030] Such as figure 2As shown, the coaxial rotor machine is mainly composed of a housing 4, a rotor 5, a power output shaft 6, a reaction plate 7, a reaction plate shaft 8, a rotary valve 9, a throttle valve 10 and a spark plug 11. The rotor 5 is coaxially installed in the central hole of the housing 4 . On the cylindrical surface of the rotor 5, two crescent-shaped through grooves are opened along the axial direction, and the boundary lines of the through grooves are F, H and J. Two grooves C are opened on the housing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com