A sampling device for thermal analysis

A sampling device and thermal analysis technology, applied in the direction of sampling device, sampling, and analyzing materials, etc., can solve the problem that thermocouples can only be used once

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

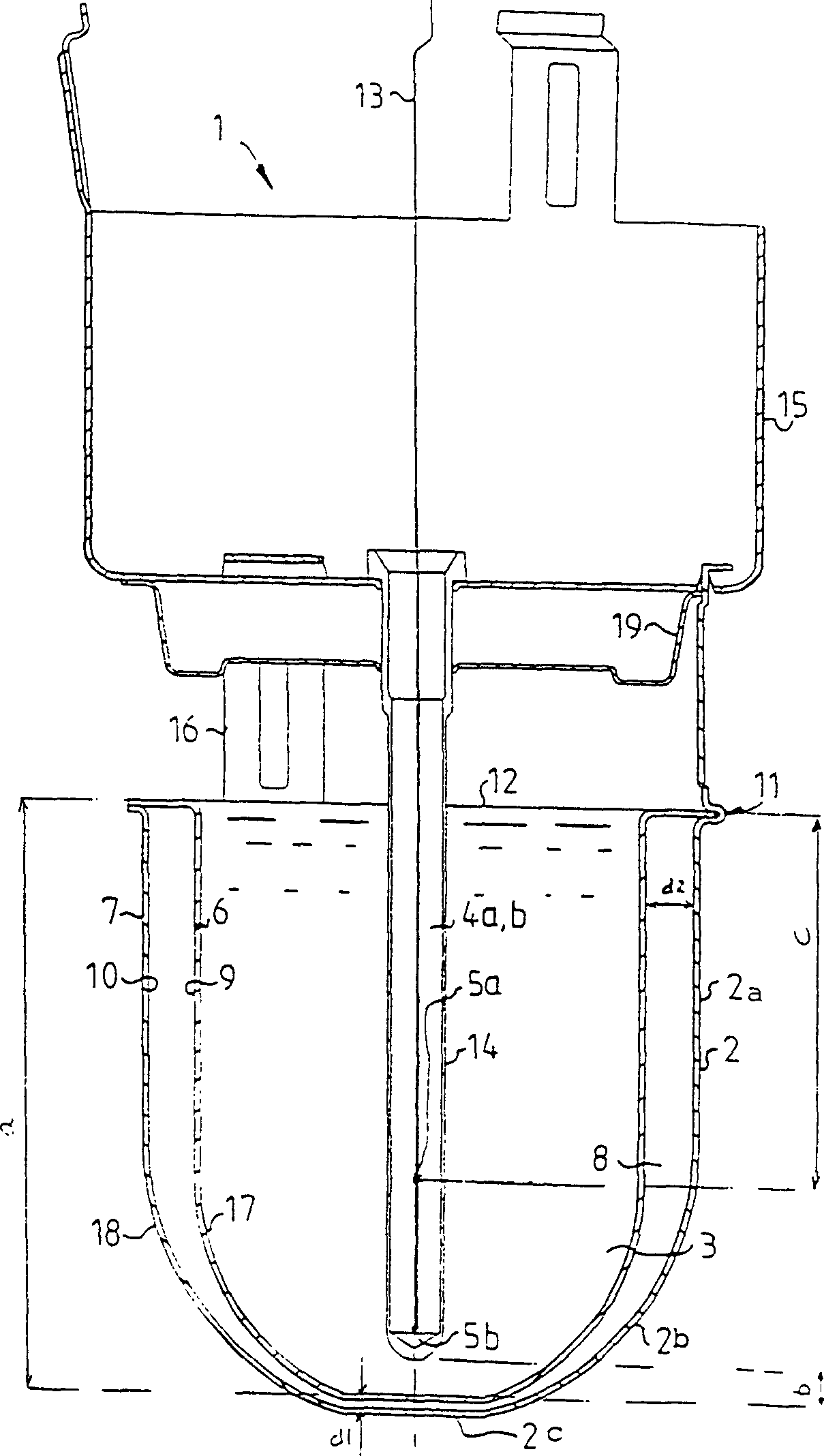

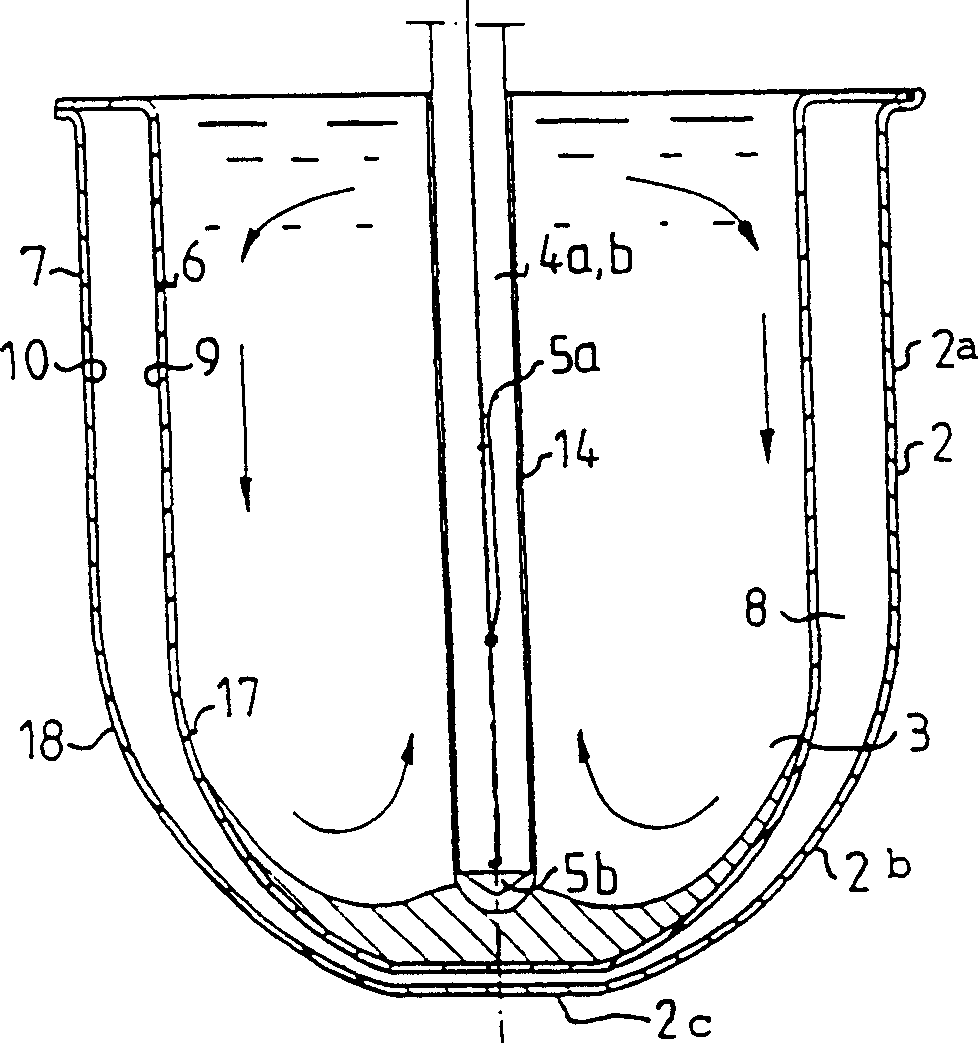

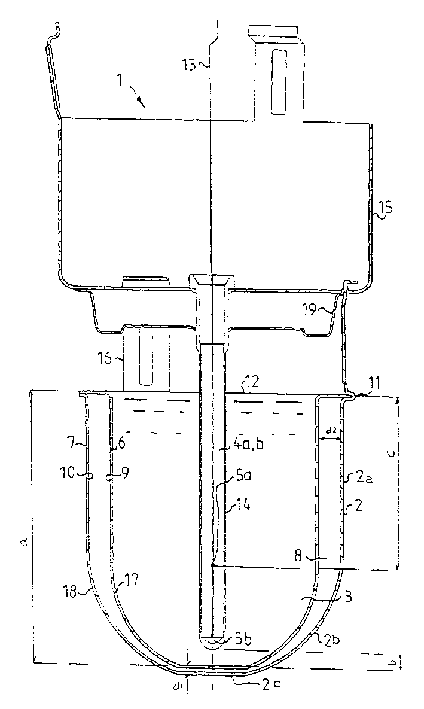

[0031] figure 1 Represents a sampling device 1 according to the invention comprising a double-walled sampling container 2, substantially cylindrical, open at the top and having a hemispherical bottom 2b provided with a flattened portion 2c, A sample 3 of solidifying molten metal is contained in a container 2 so that the sample is filled up to the mouth 12 of the container, the sampling device 1 also includes temperature-sensitive sensors 4a-b for thermal analysis and a sensor The support 15, the sensor support 15 comprises a radiation shield 19 fixed to the container 2 by legs 16, said support 15 and radiation shield 19 guide the protective tube 14 enclosing the sensors 4a-b and Hold firmly in place. The measuring portions 5a-b of the temperature-sensitive sensors (ie thermocouples in the description below) 4a-b are immersed in the sample 3 . Herein, the height of the cylindrical part 2a of the container 2 is approximately twice the height of the semicircular bottom 2b in or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com