Contact net installing machine and its working process

A catenary, mechanical technology, applied in the direction of using take-up reel/photosensitive drum layout, transportation and packaging, overhead line/cable equipment, etc., can solve the problem of constant given tension, tension drop, difficulty, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

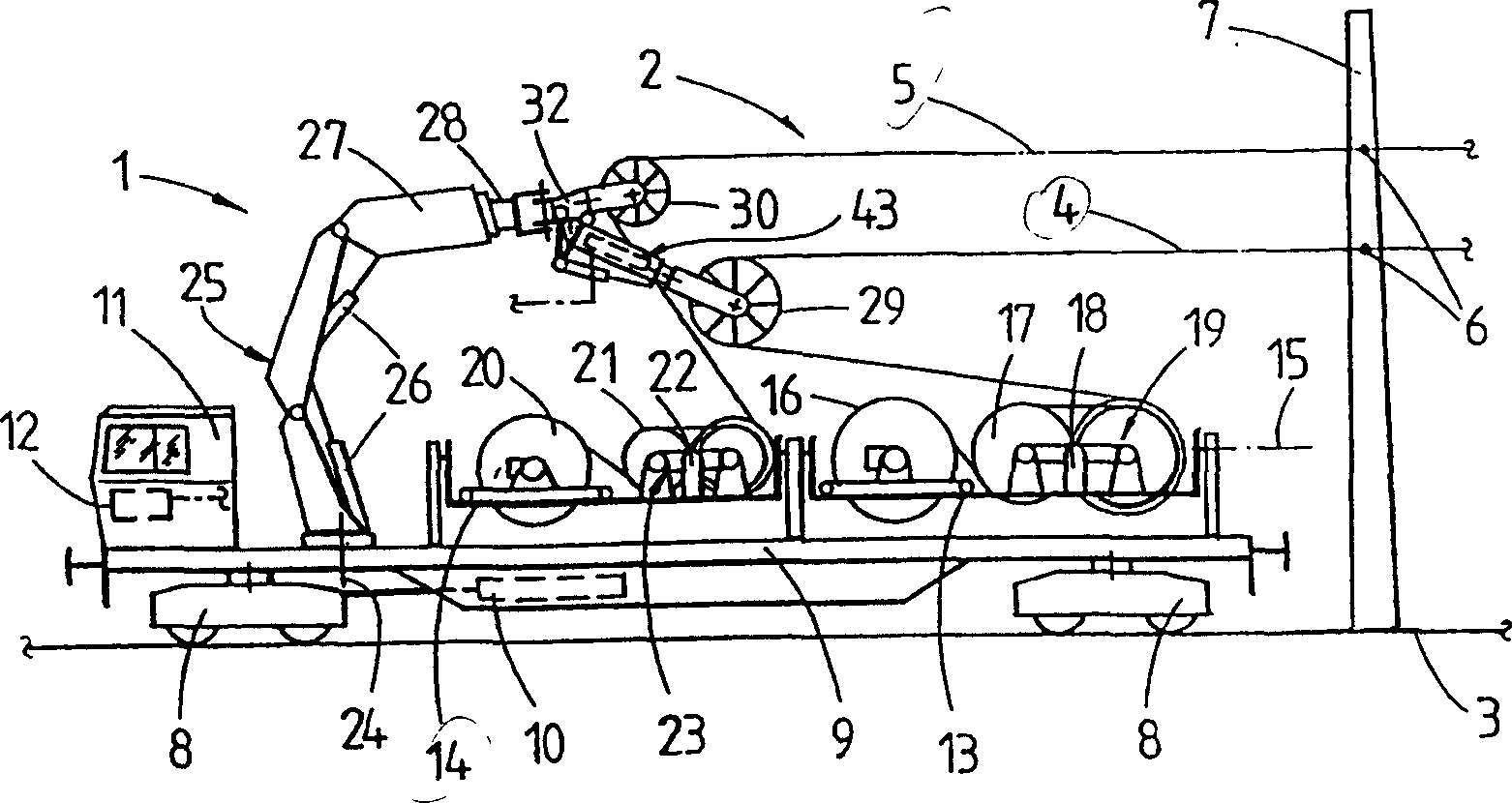

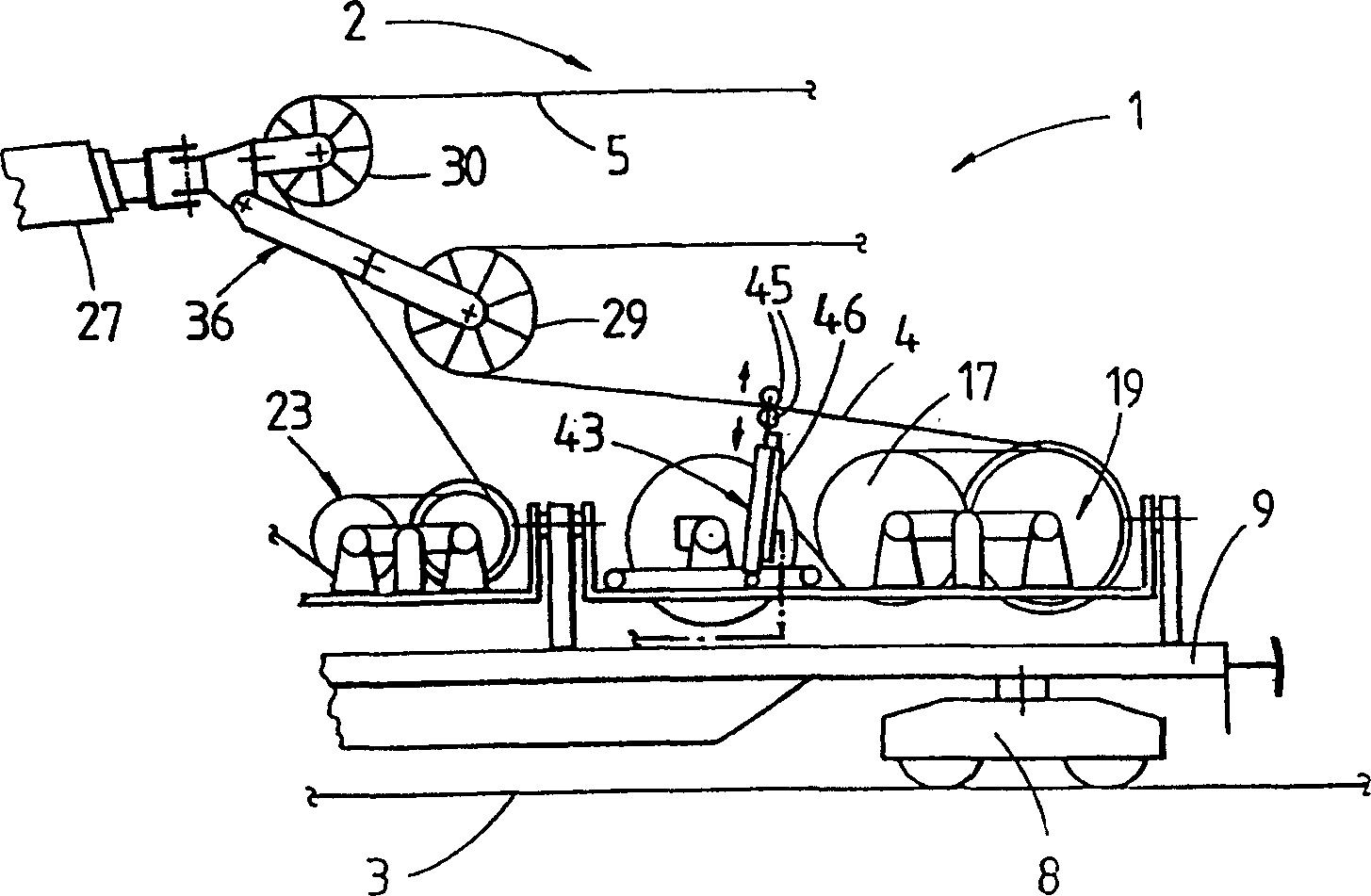

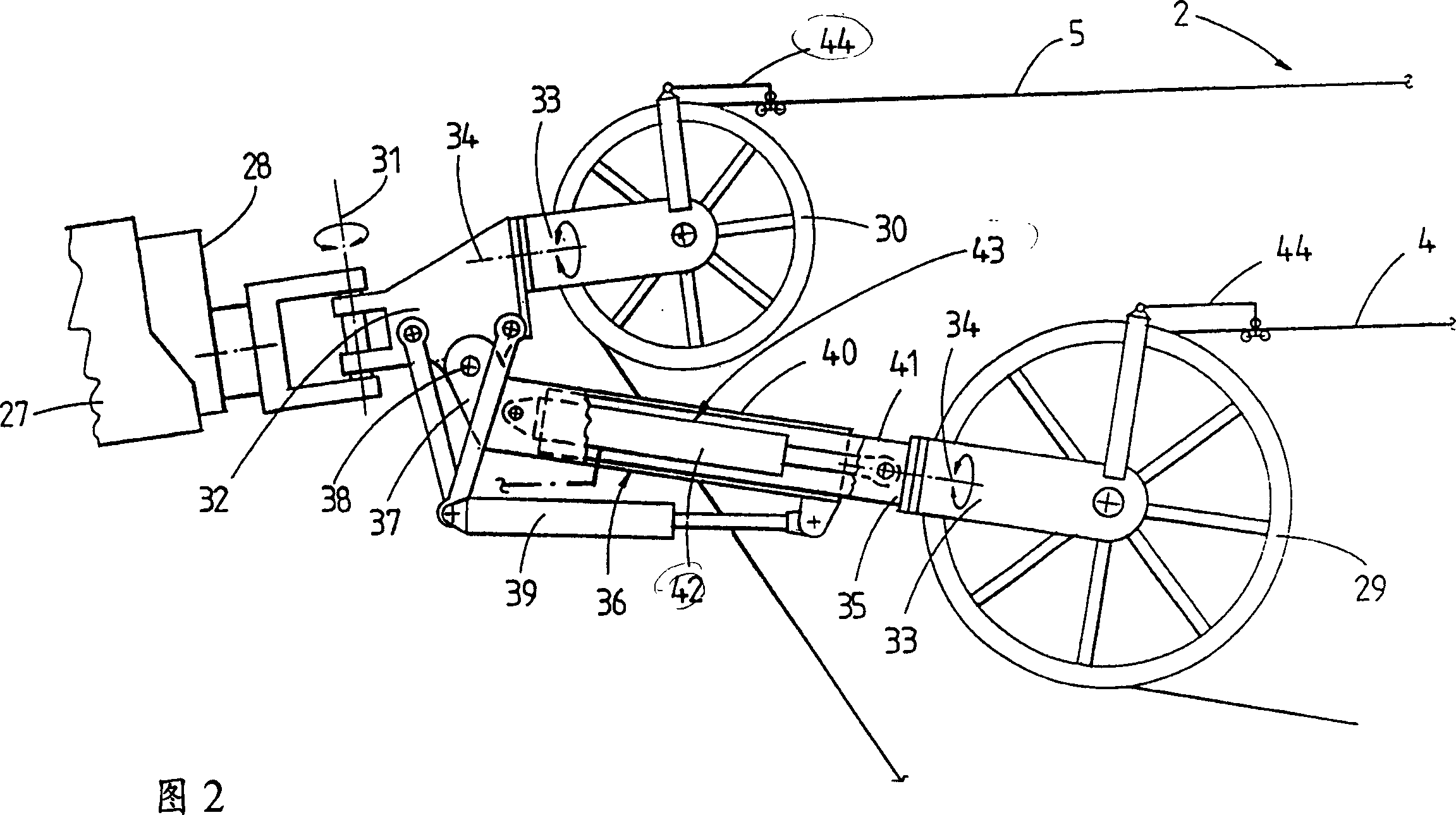

[0013] figure 1 Shown is a machine 1 for mounting rails 3 electrified catenary 2 . The catenary 2 is mainly composed of a contact wire 4 and a load-bearing cable 5 connected to the fixed point 6 of the catenary pole 7 beside the track. The machine 1 has a frame 9 supported on a rail 3 by means of a rail mechanism 8, and can travel along the rail 3 by means of a travel drive 10 and a control device 12 provided in the cab 11, ie, in the cab.

[0014] The frame 9 is provided with two supporting frames 13, 14 which are installed forward and backward along the longitudinal direction of the machine, and can swing back and forth around an axis 15 along the longitudinal direction of the machine. The carrier 13 is provided with a spool 16 on which the contact wires 4 are wound. There is also a rope winch 17 which can be actuated by means of a hydraulic drive 18 to form a tensile stressing device 19 . Similarly, a reel 20 of a load-bearing cable 5 and a rope winch 21 equipped with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com